Identifying early-stage discoloration in the ethylene-vinyl acetate (EVA) copolymer encapsulants used for crystalline solar module lamination can spot panel degradation before power output is affected.

Discoloration reduces direct short circuit current, making it a prime source of reduced panel performance, alongside premature delamination.

Researchers led by academics from the Indian Institute of Technology (IIT) Bombay have proposed a new, non-destructive method of detecting early-stage photobleaching and discoloration in EVA encapsulants. Both phenomena were described as ‘opposite reaction mechanisms’ in encapsulants by the researchers.

Discoloration, caused by the presence of conjugated compounds, volatiles and other gaseous elements, leads to the appearance of fluorophores – fluorescent chemical compounds which intercept UV light and reduce light transmittance and reflectance within PV panels. Photobleaching occurs when fluorophores are converted to non-fluorescent form and is usually localized at the edges of solar cells and does not hamper performance.

Non-destructive

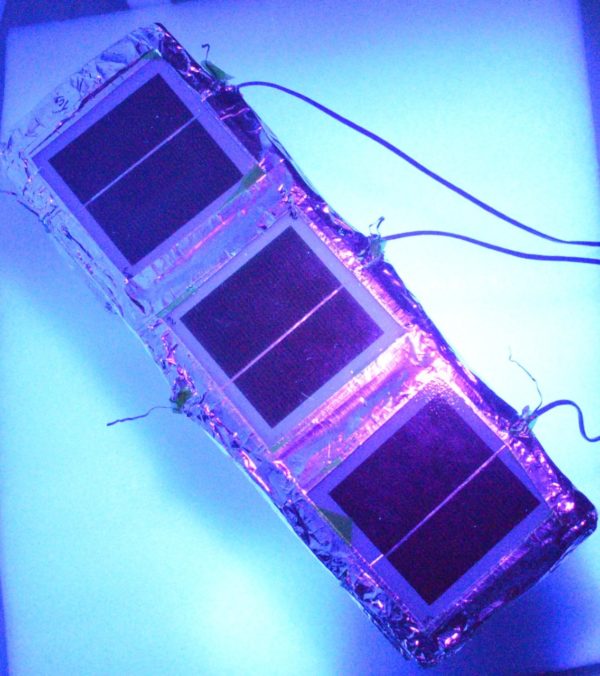

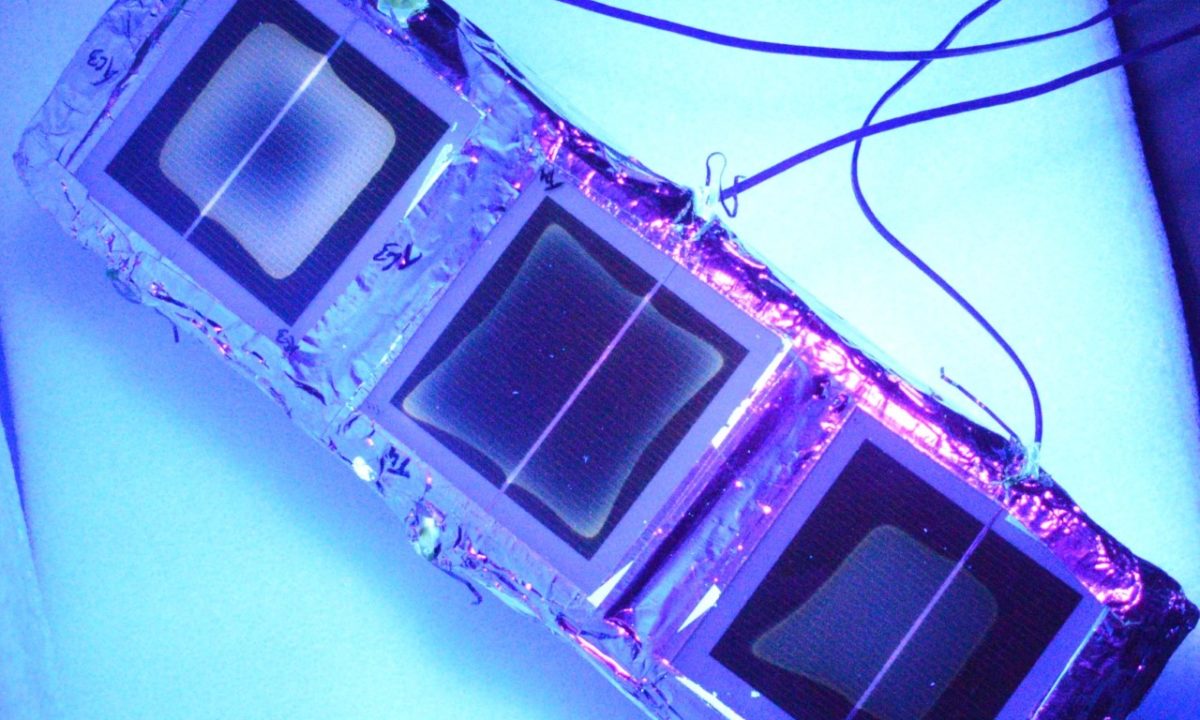

To spot early-stage discoloration and photobleaching, the IIT Bombay group used fluorescence imaging, which is typically used to detect EVA encapsulant degradation, and Raman spectroscopy, a technique used to observe vibrational, rotational and other states in molecular systems. The researchers analyzed UV-cut (C), UV-transparent (T) and combined – TC – EVA encapsulant, single-cell solar module samples in a UV accelerated-aging test. The samples were placed over 12cm thick glass wool insulation and tightly packed with aluminum tape.

The results showed the order in which the two opposite reaction mechanisms occurred differed depending upon the nature of the cell which underwent the accelerated aging process.

Image: Indian Institute of Technology

“It is found that the oxygen diffusion coefficient of the T sample is four and nine times slower than the TC and C samples, respectively, in the photobleached region,” the scientists said. “Fluorescence imaging and spectra and Raman spectra were taken before and after the accelerated test and indicated that discoloration causing fluorophore generation was higher after [photobleaching] for transparent and combined EVAs, whereas [it was] higher at the center for UV‐cut EVA laminates.”

Popular content

Different discoloration

After the aging test, the researchers analyzed the difference between the three samples with ultraviolet-visible spectroscopy and a colorimeter.

The IIT Bombay group said, after 34 days of UV accelerated-aging, their novel technique was effective at identifying early-stage photobleaching and discoloration.

“The main finding of this study is that discoloration initiation is different for the T-EVA and the C-EVA samples,” they wrote in the paper Early‐stage identification of encapsulants photobleaching and discoloration in crystalline silicon photovoltaic module laminates, published in Progess in Photovoltaics.

According to the findings, discoloration of the encapsulants began after photobleaching at the edges of cells and moved towards the central region of the T and TC samples. However, in the C sample, discoloration started from the central region and moved to the corners. “Fluorescence and Raman spectra showed that there [were] no unsaturated fluorophores present in the photobleached region, whereas the discoloration region [showed] strong unsaturated fluorophore fluorescence,” the paper noted.

“This work establishes a significant impact in the area of PV module encapsulation and may result in the industry adopting the techniques to identify the initial stages of discoloration in different encapsulants before fabricating … PV modules,” the IIT Bombay group stated. “It will also help the industry in choosing the right encapsulant material for the operation of PV modules in different climatic conditions.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.