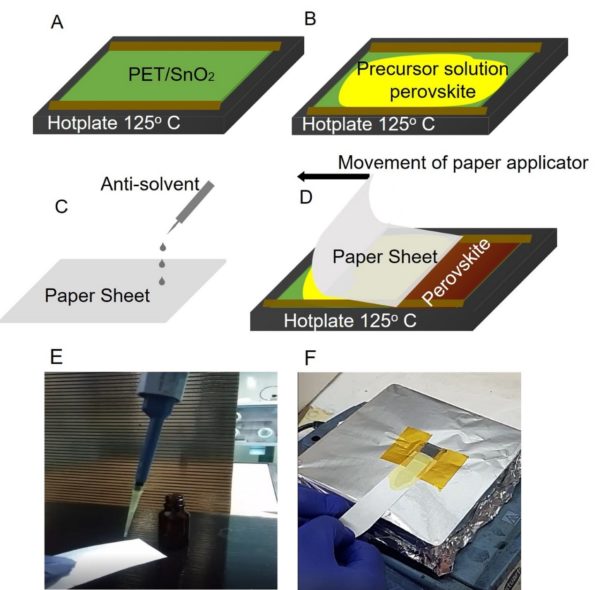

Researchers from the University of Rome Tor Vergata in Italy and the University of Zanjan in Iran have developed a new method to manufacture perovskite photovoltaic cells with just a small sheet of paper as an applicator. They claim that this eliminates the need for a spin coater or other large-area techniques such as slot-die coating or blade coating.

“This method enables the deposition of the perovskite film incredibly cheaply as well as effectively,” researcher Nazila Zarabinia told pv magazine. “The trick to achieving good solar cell efficiency is to soak the piece of paper in an anti-solvent before drawing the applicator over the precursor liquid.”

They said the novel applicator has better porosity and smoothness than other soft applicators for the deposition of high-quality perovskite films. They described the “deposition via an antisolvent soaked applicator (DASSA)” technique as an easily scalable process to produce uniform, pinhole-free perovskite films.

“We think this simple method will appeal to all those labs setting up a line in perovskite research who have not been able, for money or time, to buy expensive deposition equipment since it enables the deposition of the perovskite film incredibly cheaply,” researcher Thomas Brown explained. “It can also be of particular interest to groups developing automated printing techniques by applying the anti-solvent, not on the perovskite film as usual, but on the applicator instead.”

Image: University of Rome Tor Vergata

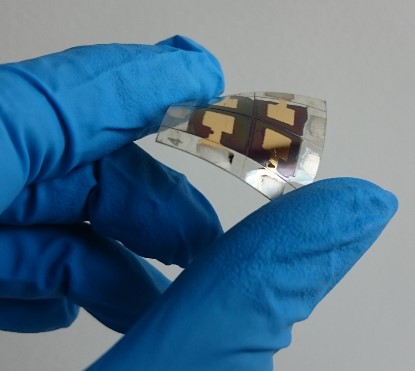

The research group tested the process on a solar cell based on a polyethylene terephthalate (PET) substrate with a power conversion efficiency (PCE) of 6.7%.

Popular content

“When the paper applicator was soaked in the green antisolvent, ethyl acetate, the maximum PCE jumped to 11.1%,” the scientists said. “By soaking the applicator with antisolvent, double cation perovskite films with increased uniformity, crystallinity, and better-interconnection were obtained as evidenced by analysis of the PL, SEM, and XRD measurements.”

For comparison, a similar device developed with spin coating and an antisolvent method achieved an efficiency of 14.9 %. The researchers said that this shows there is scope for further improvement.

“Setting up an automated system that would carry out the application more precisely compared to the manual deposition we implemented here would improve macroscopic and microscopic film uniformity as well as performance and reproducibility,” they said.

The researchers described the new manufacturing process in “Simple and effective deposition method for solar cell perovskite films using a sheet of paper,” which was recently published in iScience.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.