Scientists at the US Department of Energy’s Pacific Northwest National Laboratory (PNNL) have developed an aluminum-nickel (Al-Ni) molten salt battery that, under thermal cycling, exhibits high retention of cell capacity over periods of weeks.

The scientists described the small prototype as a “freeze-thaw battery” that cuts off the self-charge function when a battery is idling. “It’s a lot like growing food in your garden in the spring, putting the extra in a container in your freezer, and then thawing it out for dinner in the winter,” explained researcher Minyuan Miller Li.

The battery is charged by heating it to around 180 C, with its ions flowing through the liquid electrolyte. The device is then restored to room temperature and the electrolyte becomes solid, thus trapping the ions that transport the stored energy.

“The freeze-thaw phenomenon is possible because the battery’s electrolyte is molten salt – a molecular cousin of ordinary table salt. The material is liquid at higher temperatures but solid at room temperature,” the scientists said.

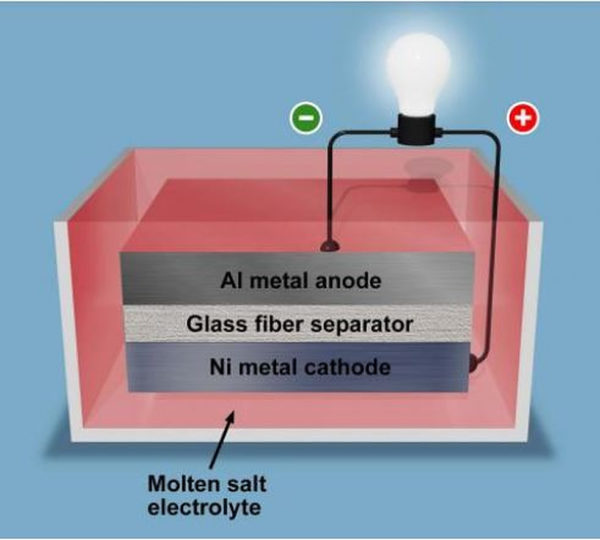

They noted that the battery can be heated again, as the ions restart flowing through the electrolyte when energy is needed. They built it with an aluminum anode and a nickel cathode, immersed in a sea of molten-salt electrolyte.

Image: Mike Perkins, PNNL

They added sulfur to the electrolyte to increase the battery’s storage capacity. A ceramic separator was embedded between the anode and the cathode to avoid breakage during the freeze-thaw cycle.

Popular content

“The PNNL battery uses simple fiberglass, possible because of the battery’s stable chemistry. This cuts costs and makes the battery sturdier when undergoing freeze-thaw cycles,” said the scientists.

They claimed that the battery can retain 92% of its initial capacity over a period of 12 weeks. They said it has a theoretical energy density of 260 W/hours per kg.

“The battery’s energy is stored at a materials cost of about $23 per kilowatt-hour, measured before a recent jump in the cost of nickel,” they said. “The team is exploring the use of iron, which is less expensive, in hopes of bringing the materials cost down to around $6 per kilowatt-hour, roughly 15 times less than the materials cost of today’s lithium-ion batteries.

The scientists described the battery in “A freeze-thaw molten salt battery for seasonal storage,” which was recently published in Cell Reports Physical Science.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

The higher operating temp. will cost some energy!

Don’t worry about it, global warming has it covered

What is the efficiency once the thermal cycling is included?

What’s the cycle efficiency?

How many cycles will it last?