A group of scientists from Durham University in the United Kingdom has proposed the use of Brayton pumped thermal energy storage (PTES) for the storage of large-scale grid electricity, in the form of high-grade thermal energy.

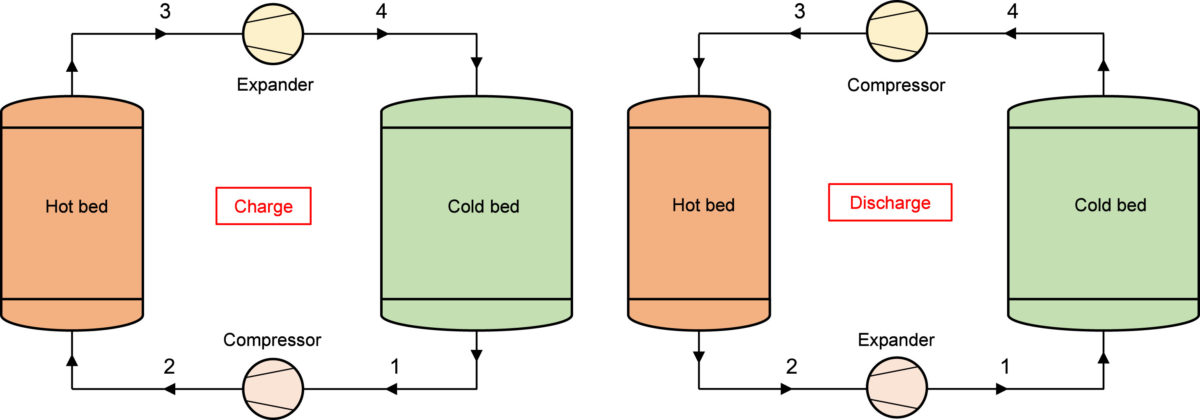

PTES systems use a running thermal cycle to transform low-temperature heat into high-temperature heat and then store it in a thermal storage unit during charging. The systems allow higher storage efficiencies than the direct electric heating of the thermal storage unit and are purportedly a promising way to manage intermittent renewable energy. The technology modeled by the UK group is based on the so-called Brayton cycle and involves the use of reversible heat-pump and heat-engine cycles to store electricity in the form of thermal energy.

“The system operates as a heat pump cycle during charge followed by a heat engine during discharge,” the scientists explained. “Thermal energy is transferred to the working fluid during compression and expansion.”

The proposed Brayton PTES system is based on thermal storage in packed beds, which includes heat transfer mechanisms within the system itself. The packed beds were modeled as well-insulated tanks storing thermal material without heat leakage. Latent heat storage, which exploits the melting and solidification phenomena of a phase change material (PCM) to absorb or release heat, was used to maximize the duration of the high power region and increase the overall efficiency of the system.

“The volumes of the tanks were increased and PCMs added downstream of the main storage section; the length of each store was increased by 50%,” the scientists said. “Specific analysis will be required in the implementation of individual PCMs with each system if they are to be commercially deployed in the future.

The system is based on a Brayton PTES concept demonstrated by UK-based Isentropic Inc. It consists of two insulated containers filled with crushed rock or gravel, a hot vessel working at high temperature and high pressure, and a cold vessel operating at low temperature and low pressure. The two vessels are connected via pipes and the whole system is filled with argon, an inert shielding gas that is mostly used in high-temperature industrial processes.

Popular content

The modeled system was assumed to have a nominal power of 1 MW and a storage capacity of 4 MWh. It was based on packed bed hot and cold storage tanks relying on magnetite with a motor-generator connecting the compressor expander (CE) on a single shaft. Magnetite was selected due to its high specific heat, following a concept developed in the Isentropic demonstration system.

Through their modeling, the researchers found that the addition of latent heat storage could improve overall system efficiency to up to 80%.

“As discharge time was constrained by renewable energy source and market conditions, the objective of this study was to maximize the duration of the high power region and decrease the size of the power front in compressor expander (CE) device. This can be achieved by elongating the tanks and increasing the segmentation temperature ratio,” they said. “It is recognized that use of the highly efficient reciprocating CE devices contributed to the high predicted efficiency of the system and other assumptions such as ideal electro-mechanical conversion are also likely to reduce the energy reclaimed in discharge in a real system.”

They presented their findings in “Operation and performance of Brayton Pumped Thermal Energy Storage with additional latent storage,” which was recently published in Applied Energy.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Instead of all their fancy calculations, they could have just said that they assume 106% of the ideal Carnot cycle efficiency (84.1%) to reach their stated round trip efficiency of 89.0% (Table 4). #TooManyOptimisticAssumptions #QED 🤣

@KeithDPatch