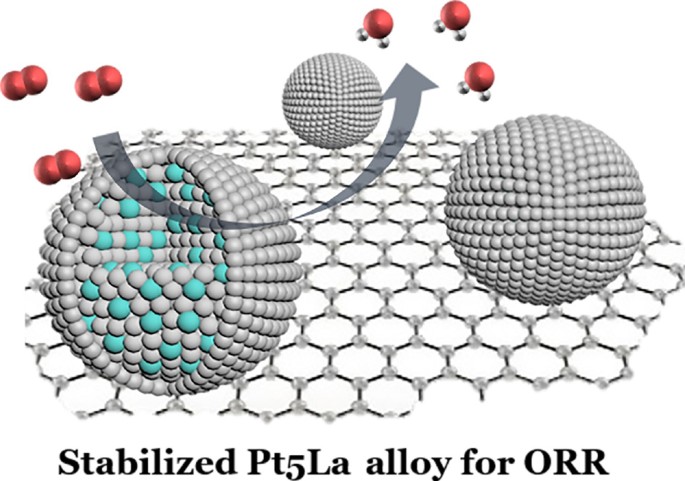

Tsinghua University researchers have devised a way to combine high-cost platinum and a low-cost rare earth element, lanthanum, as an alloy to serve as a catalyst in fuel cells. The team obtained readily available lanthanum salts and trimesic acid, and these two precursor materials then self-assembled themselves into nano-scale “rods.” These nanorods were then impregnated with platinum at 900 C. The resultant platinum-lanthanum nanoparticles were then stress-tested for their performance in a fuel cell. “The resultant Pt5La alloy catalyst exhibits enhanced activity with half wave of 0.92 V and mass activity of 0.49 A·mgPt−1, which strictly follows the 4e transfer pathway,” the researchers wrote in “Ultra-stable Pt5La intermetallic compound towards highly efficient oxygen reduction reaction,” which was recently published in Nano Research. They said that the catalyst exhibits superior stability after 30,000 cycles of the accelerated stressed test, with mass activity retention of 93.9%.

Vattenfall, Swedish steelmaker SSAB, and Swedish state-owned miner LKAB have revealed new research showing the promising properties of hydrogen direct reduced sponge iron (H-DRI). Their HYBRIT project focuses on the use of hydrogen to produce ore-based steel, instead of coking coal. “Hydrogen-reduced carbon-free DRI produced with HYBRIT technology in the pilot plant is highly metallized and has superior mechanical and aging properties compared to direct reduced iron using fossil-based reducing gas such as natural gas,” said SSAB. The partners said they aim to start industrial production of H-DRI by the end of the decade, starting with a pilot facility in Gällivare, Sweden.

Salzgitter and Sunfire have completed the EU-funded GrInHy2.0 project with “record production” of roughly 100 tons of green hydrogen to make green steel. They have operated a high-temperature electrolyzer from Sunfire with an electrical connected load of 720 kW on the premises of Salzgitter Flachstahl since 2019. The partnership between Sunfire and Salzgitter is set to continue beyond GrInHy2.0.

Popular content

Sasol and ArcelorMittal have partnered to develop carbon capture technology and produce green steel. Under a joint development agreement, they will assess the potential of Saldanha, South Africa, as an export hub for green hydrogen and derivatives. They will also focus on ways to use renewable electricity and green hydrogen to convert captured carbon into fuels and chemicals, according to a statement.

Petronas and Heriot-Watt University have started a new research partnership, with plans to use thermochemical reactions to produce hydrogen from biomass and other waste materials. The GBP 1 million ($1.1 million) research project will also explore solutions to address scalability and storage to promote adoption globally. They will focus on using the estimated 4 million tons of waste and by-products created by distilleries in the United Kingdom and the approximately 127 million tons of agriculture waste generated for hydrogen production every year in Malaysia.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.