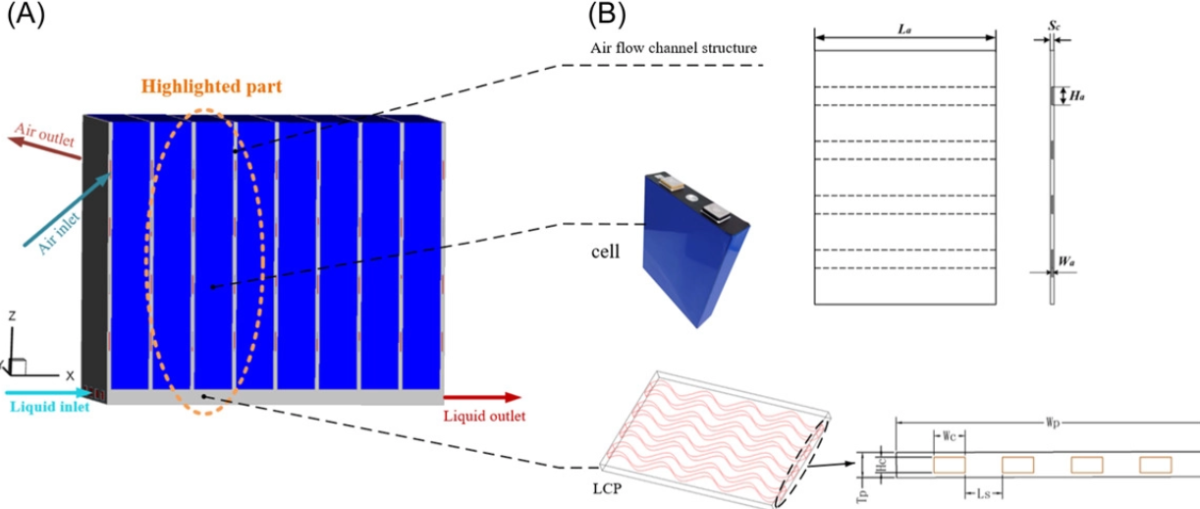

Nanjing Forestry University researchers in China have developed a novel cooling system of liquid cold plates coupled with air flow channels (LCP-AFC) to improve the thermal performance of EV batteries. They studied the effects of five factors on the heat dissipation of the EV battery module, including the battery discharge rate, inlet temperature of cooling liquid, nanofluids, airflow velocity, liquid, and air flow directions. The results showed that the maximum temperature and temperature difference of the battery module under a 1 C discharge rate could be reduced by 1.1 C and 0.92 C compared to the single liquid cooling. Comparing the LCP-AFC with single air cooling, the maximum temperature and temperature difference of the battery module under a 4 C discharge rate could be reduced by 18.74 C and 2.71 C. The temperature uniformity of the battery module was not satisfied with the inlet temperature of the cooling liquid, which was lower than 15 C. The heat transfer performance was improved by adding Al, Cu, or Ag nanoparticles into the deionized water. Among them, Ag–water nanofluid had the most significant cooling effect. Parallel flow indicated better thermal performance than cross flow and counter flow. The researchers described the system in Energy Science and Engineering.

SK is developing a battery diagnosis service for electric vehicles, with plans to add it to its own charging stations next year. It is developing the new service with its battery unit, SK On, and its charger subsidiary, SK Signet. SK On's battery-as-a-service (BaaS) will analyze data from SK Signet's rapid chargers, and measure battery life and condition in real time when users plug in. They said 50 kW chargers will 30 minutes to diagnose, and the faster the charging speed, the shorter the time. The results will displayed through the charger screen and a planned app.

Xelectrix Power and Mobilespace have agreed to jointly develop a mobile power storage device with an integrated automatic transfer switch (ATS), for on- and off-grid charging. The 80 kW Ecobaze system has a capacity of 160 kWh – enough to cover all of the energy needs of a typical movie set – and can be charged with a PV system or from the grid. The generator can fully charge the storage system within 1.5 to two hours, with an output of up to 100 KW whenever storage reaches its minimum state of charge (SoC). The system can supply basis demand (60 kWh to 120 kWh) for between one to three days without the need to turn on the diesel generator, and can supply loads up to 80 kW. The generator only turns on if the SoC reaches its minimum, or if the load is higher than the rated power of the 80 kW storage system inverter. The storage system and generator can together supply loads up to 180 kW.

BMW Group plans to build assembly lines for the high-voltage batteries next to its new vehicle plant in Debrecen, Hungary. Production of the battery packs is expected to begin in parallel with vehicle production by the end of 2025. The Munich-based carmaker is investing more than €2 billion ($2.08 billion) in the plant, where it will make its sixth-generation batteries, as it switches from prismatic to round cells in its New Class vehicles. It will build the new batteries according to the “pack-to-open-body concept” for a system voltage of 800 V.

Mazda has unveiled a $10.6 billion plan to electrify its fleet of vehicles. The Japanese carmaker said it also might invest in battery production. “We estimate Mazda's EV ratio in global sales to rise to a range between 25% and 40% as of 2030,” the company said in a statement, noting that it is working with partner companies on a range of electrification-related research projects. One of them, in partnership with Rohm and Imasen Electric Industrial, focuses on the development of inverters with silicon-carbide power semiconductors – one of the core parts of an electric drive unit. Imasen is also involved in a separate 50:50 collaboration with Mazda to develop inverters and production tech for components such as circuit boards.

Popular content

VinFast has shipped its first batch of EVs. The Vietnamese carmaker is exporting 999 units of its VF 8 model to the United States. The shipment is the first batch of 65,000 global orders already made for the VF 8 and VF 9, according to the company. More VF 8 SUVs will be exported to Canada and Europe in early 2023. VinFast is also building an EV plant in North Carolina, pending final regulatory approval.

ABB has raised around CHF 200 million ($211.5 million) from the sale of an 8% stake in its EV charging business. It will retain 92% of E-mobility, as it aims to list its shares in the second half of 2023. The list of buyers includes investors linked to IKEA and AMAG, and proceeds from the stake sale will be used to expand E-mobility and make hardware and software acquisitions, said ABB.

Batri and its international consortium partners are working on a renewable energy transport hub in Swansea, Wales. The group includes DST Innovations, Siemens, construction giant HDR, and infrastructure specialist Enable. The hub will feature electric and hydrogen charging facilities for cars, public transport vehicles, e-bikes, and e-scooters, as part of a larger scheme to reinvent Swansea's dock area. The plans includes a tidal lagoon, a data center, a battery factory, green hydrogen production, floating solar panels, and a battery storage facility for the renewable energy generated on site. Other elements of the scheme include affordable homes and a climate change research center. Subject to planning consent, work is scheduled to start on the project in 2023.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.