Chinese PV Industry Brief: DMEGC to build 20 GW TOPCon cell factory

DMEGC has revealed plans to build a 20 GW solar cell factory in Sichuan province, while Daqo said it has secured long-term polysilicon supply agreements with Longi and another undisclosed Chinese company.

US Customs clears solar panels after holding them over forced labor fears

The US authorities have cleared a significant supply of JinkoSolar modules, made with Wacker polysilicon, for sale in the US market, according to ROTH Capital Partners.

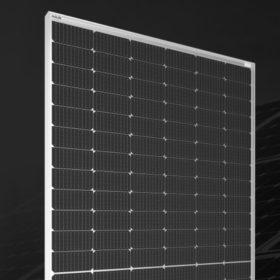

Goldi Solar releases 520-550 W line of mono PERC solar panels

India’s Goldi Solar has unveiled the HELOC Pro series of mono PERC solar modules, which are built with PV cells made in India. They are available in mono facial and bifacial variants, with power outputs ranging from 520 W to 550 W.

Agrivoltaics to reduce water evaporation

Chinese scientists assessed water evaporation on plots of land covered by two different kinds of agrivoltaic arrays and managed to significantly reduce evaporation in both cases. They looked at the relationship between cumulative surface evaporation and evaporation time.

Novel method to calculate variations in temperature coefficients of solar modules

Brazilian scientists have assessed variations in temperature coefficients in solar modules to determine whether there is a relationship between the dependence of these coefficients and irradiance. They claim their work could be used to improve PV module performance modeling.

Hevel Solar unveils 450 W heterojunction solar panel with M6 cells

Russia’s Hevel Solar said its new modules are based on 166 mm x 166 mm half-cut cells. They reportedly have a bifaciality factor of 90% and a temperature coefficient of -0.26% per degree Celsius.

Itochu to start recycling solar modules

Japan’s Itochu has announced a new tie-up with France’s Rosi Solar, which develops tech to recover and recycle high-purity silver, copper and silicon from solar modules.

Luminescent solar concentrators for agrivoltaics, greenhouses

Moroccan researchers have proposed the use of luminescent solar concentrators for power generation in greenhouses and agrivoltaic projects. They say they are capable of producing electricity in low-light illumination and converting ultraviolet light to visible light that could be used for crops.

Chinese PV Industry Brief: TCL Zhonghuan cuts wafer prices by more than 4%

TCL Zhonghuan has announced wafer price cuts, Shenzhen Energy unveiled a plan to build a 2 GW solar-storage project, and the Chinese authorities have announced measures to expedite grid connections for new solar and wind plants.

Perovskites and microgrooves can revolutionize solar

Ambitious targets for solar energy generation present challenges to an industry keen to explore new avenues for solar production. Neil Spann, chief executive of UK thin film solar manufacturer Power Roll, describes a commercial solution to the problems of over reliance on silicon solar modules.