TOPCON solar cell, is touted as the next generation of solar cell technology after PERC. This novel architecture is introduced by researchers at Fraunhofer Institute for Solar Energy Systems in Germany in 2013.

TOPCon is a “tunnel oxide passivated contact solar cell” technology based on the principle of selective carriers, whose structure is N-type silicon substrate cells, prepares an ultra-thin layer of silicon oxide on the back of the cells, and then deposits a thin layer of doped silicon, which together form a passivation contact structure, effectively reduces surface composite and metal contact compounding, and provides more space for N-PERT battery conversion efficiency.

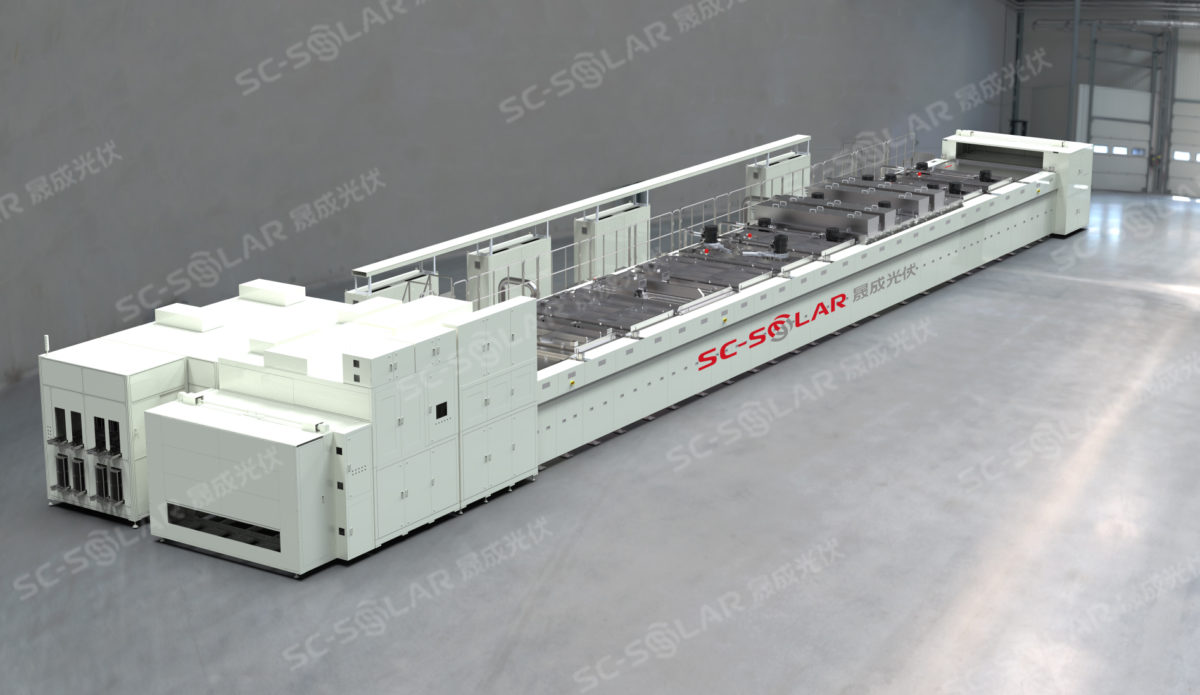

Since 2020, SC SOLAR devise cost-driven strategies towards industrial manufacturing of TOPCon-based solar cells after assessing various process routes based on currently production-ready and upcoming future alternative process technologies. This week, First TOPCon two-in-one deposition tool was launched.

SC SOLAR's TOPCon two-in-one deposition tool was a combination of PECVD and PVD technologies to prepare the backside tunneling silicon dioxide layer and doped silicon (carbide) layer, this method can reduce or even avoid the wrap-around problems caused by LPCVD. This technical method can also improve the weakness of layer bursting, low life of graphite boat and unstable mass production which are prone to occur in tubular PECVD. Meanwhile, it can avoid using a large-scale linear ion source, which is relying on imports, high cost and poor uniformity.

SC SOLAR's TOPCon two-in-one deposition tool can effectively improve the passivation quality of the layer, with addition of silicon carbide layer can reduce the wavelength-loss and improve the current density of TOPCon cells. Meantime, in-line configuration has the strengths of high productivity, low temperature, and excellent layer quality, compatible with silicon wafers of different sizes from M2 to M12. It improves the yield of TOPCon cells and the average conversion efficiency of mass production, and helps reduce production energy consumption and equipment costs.

At present, the first-generation TOPCon two-in-one deposition tool developed by SC SOLAR is named SHENGYAO series, different models and specifications can be customized according to customer requirements.

By Reducing the deposited poly-Si thickness, the impact of the wrap-around can be diminished. A wrap-around of poly-Si onto the edges and the front side of the cells that may occur, SC SOLAR also has developed an easy BOE de-wrapping cleaning machine to help customers.

SC SOLAR has been not only designed to meet our customers’ requirements, based on comprehensive solar cells application experience but also cooperated with solar photovoltaic manufacturer all around the world, and keep its market leader position in assembly line installations. The delivery of the TOPCon two-in-one deposition tool once again proved the company's technological innovation capabilities. Up to now, SC Solar has advanced technology reserves and actual product sales in the fields of high-efficiency solar cells and modules such as TOPCon, HJT, and perovskite.

In the future, SC Solar will continue to devote itself to accelerating the intelligent process of the whole industry chain of PV industry, making PV manufacturing more efficient, safer and easier.