New design for photovoltaic-thermal panels mitigates risk of cracking

Researchers in Sweden have developed a new PVT module using an aluminum alloy structure between the thermal absorber and the photovoltac cells. This architecture reportedly reduces thermal expansion by 20%, thus increasing the chances of mitigating cracks in the PV unit.

Laser optimization for half-cut solar cells

Scientists in Korea examined the parameters of laser ‘scribe and break’ processes used to cut silicon cells, in search of optimizations to reduce damage caused at the cut edges. They also found that varying encapsulant thickness or even adding a supportive rail across the back of a module can help reduce performance loss caused by cell cutting damage.

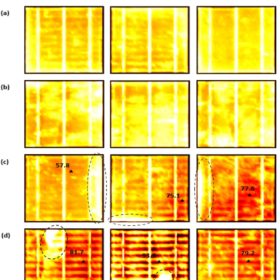

Damaging defects in silicon solar cells

Scientists in the UK investigated the relationship between two of the most worrisome defects that can affect solar cells in the field – cracking and hotspots. Their work analyzed solar cells with different levels of cracking under varying light conditions, finding that the most severely cracked cells were considerably more likely to run at high temperatures and form damaging hotspots.

Webinar Q&A: A recipe for improved performance

In a recent pv magazine webinar, module degradation experts took our audience through the role of temperature and mechanical stress in causing modules to under-perform. We were treated to a look at some impressive results for modules integrated with Coolback – a solution that replaces the backsheet/rear glass and frame in a conventional panel and promises lower operating temperatures and better mechanical strength. Here, Simon Meijer and Alex Masolin, from Coolback – along with Fraunhofer ISE’s Andreas Beinert – answer some of the questions we didn’t have time for during the live broadcast.

AI identifies a $14bn solar problem

How do you know when an inverter or module is under-performing? Monitoring services should shed light on problems but AI-driven digital asset manager Raycatch says much information is hidden behind a wall of “noise.” Breaking that wall with advanced data analysis could unlock billions of cost savings.

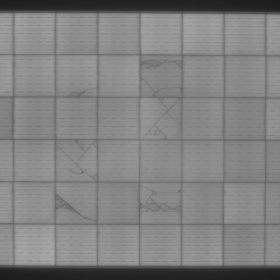

Looking into the cracks

A white paper published earlier in December by PV Evolution Labs investigates the formation of performance damaging cracks in PV cells, based on mechanical stress testing of more than 40 commercially available PV modules. While the lab warns that susceptibility to cracking will change according to the specific bill of materials making up each module, certain technologies are shown to perform better than others.

PV module recycling should prioritize high-purity silicon recovery

Recovering silicon of the quality required for reuse in panels is at the heart of mitigating device carbon footprints. R&D efforts should be ramped up now, says an international research group, so the technology is in place when huge volumes of modules begin to need replacing.