Integration on hold: Energy Taiwan 2023

This week, pv magazine was in Taipei for the Energy Taiwan exhibition. The island is moving forward on net-zero ambitions and hosts a renewable energy industry ready to support other companies in achieving them. There is much focus on energy storage and grid integration, as Taiwan looks to create space in its grids for more renewable energy. However, with elections upcoming in early 2024 and one party likely to favor nuclear over renewables, many projects are now on hold.

New production process could double wafer throughput to up to 20,000 per hour

Scientists from Germany’s Fraunhofer ISE – together with a consortium of plant manufacturers, metrology companies, and research institutions – have developed a new production line concept for high-efficiency silicon cells, with a throughput of 15,000 to 20,000 wafers per hour – roughly double the usual amount.

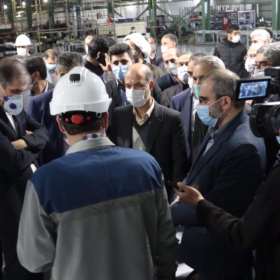

Iran brings 150MW solar cell factory online

Dec. 23 saw the inauguration of a new solar cell factory in the city of Khomeini, according to the Iranian government’s Renewable Energy and Energy Efficiency Organization. The factory, operated by Tehran headquartered company Mana Energy Pak, will be among the first in the region to produce silicon solar cells.

ITRPV: More work needed to process 210mm wafers

In an update to its annual International Technology Roadmap for Photovoltaics, German engineering association VDMA discusses the readiness level for various technologies in PV cell and module manufacturing, finding that more process development is needed for 210mm wafers – the largest format currently on the market – to match the throughputs that will soon be achievable with smaller formats including 182mm.

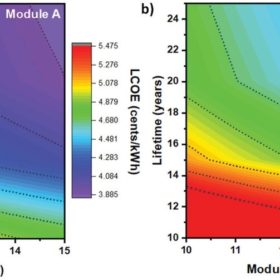

Analyzing the opportunity for perovskite solar module production in India

Scientists in India conducted a techno-economic analysis for a 100 MW production line for carbon-electrode perovskite solar modules, located in Himachal Pradesh, India. The analysis concludes that, even at the smaller scale, this emerging technology could achieve cost levels comparable with today’s silicon solar products.

ITRPV: Large formats are here to stay

The 2021 edition of the International Technology Roadmap for Photovoltaics (ITRPV) was published today by German engineering association VDMA. The report, which forecasts technology trends across the solar industry, expects PERC to maintain its position as the dominant cell technology and notes that large wafer formats are here to stay.

Simulating PV’s silver future

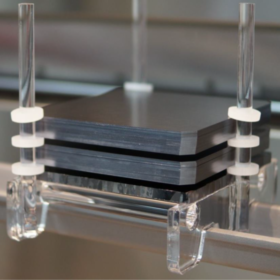

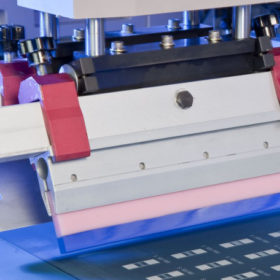

Scientists at Germany’s Fraunhofer ISE developed a model to simulate different setups for screen printing in solar cell metallization. The model provides a comparable ‘screen utility index’ value that can predict the usefulness of different architectures in the printing equipment in relation to the properties of a given silver paste. The approach, says Fraunhofer, will assist the PV industry in reducing the amounts of silver needed in silicon cell manufacturing.

RENA picks up 15 GW equipment order

Germany based PV equipment supplier RENA Technologies has received what it describes as its ‘biggest ever order’, from a tier 1 manufacturer in Asia, for 15 GW of its wafer texturing equipment. Financial details of the deal have not been disclosed, although the company states that the order is worth “tens of millions of euros.”

Slimming down on silver

Using an innovative high-speed video setup, scientists in Germany were able to observe the screen-printing process used in solar cell metallization, on a time scale of less than 50 milliseconds. Insights into the paste’s behavior and the mechanisms at work during screen printing will improve the process and the formulation of the silver paste it relies on.

Meyer Burger seals $100 million HJT order, expects to hit break-even in first half

Swiss equipment supplier Meyer Burger has signed a contract to supply heterojunction cell manufacturing equipment to an unnamed North American manufacturer. The company also posted its preliminary results for the first half, posting a $14 million EBITDA loss but stating it expects to break even for the period after selling its wafer business.