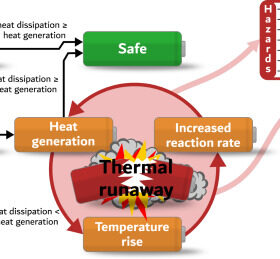

How safe are lithium iron phosphate batteries?

Researchers in the United Kingdom have analyzed lithium-ion battery thermal runaway off-gas and have found that nickel manganese cobalt (NMC) batteries generate larger specific off-gas volumes, while lithium iron phosphate (LFP) batteries are a greater flammability hazard and show greater toxicity, depending on relative state of charge (SOC).

Weekend Read: A battery worth its salt

While lithium ion battery prices are falling again, interest in sodium ion (Na-ion) energy storage has not waned. With a global ramp-up of cell manufacturing capacity under way, it remains unclear whether this promising technology can tip the scales on supply and demand.

The Battery Cycle part two: Device lifespan

Having discussed battery chemistry in a previous article, Volytica diagnostics here examines the causes of battery degradation and how to extend device lifetimes, ahead of a pv magazine webinar tomorrow.

The Battery Cycle: NMC, LFP, LTO – What’s the difference?

With battery storage such a crucial aspect of the energy transition, lithium-ion (li-ion) batteries are frequently referenced but what is the difference between NMC (nickel-manganese-cobalt), LFP (lithium ferro-phosphate), and LTO (lithium-titanium-oxide) devices and their underlying chemistry?

New nickel-manganese-cobalt battery for maritime applications

EST-Floattech has developed a nickel-manganese-cobalt (NMC) energy storage system for maritime applications. The are two versions of the battery modules, with storage capacities of 5.8 kWh or 10 kWh. The company also plans to offer a variant with lithium iron phosphate (LFP) battery chemistry.

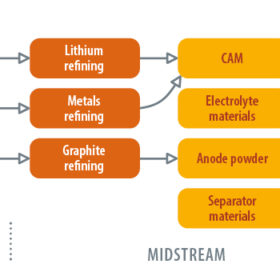

Battery supply chain state of health

As the US Uyghur Forced Labor Prevention Act demonstrated, companies preparing to spend big on batteries are at risk of being blindsided by supply-chain-related legislation. Here are some tips on how US developers can anticipate policy curveballs.

Analyst predicts 2030 bidding war for dead EV batteries

A lack of end-of-life batteries this decade is likely to play into the hands of Chinese recyclers located near most of the world’s production facilities, according to analyst WoodMac, but might at least help rebalance the current situation in which new products are cheaper than recycled ones.

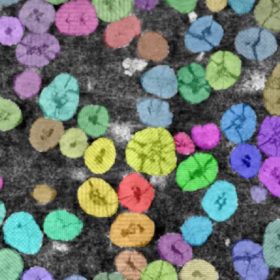

A closer look at battery degradation, assisted by machine learning

Scientists at the SLAC National Accelerator Laboratory in the U.S. have developed a machine learning algorithm that can identify and track individual particles within a lithium-ion battery cell. Their findings shed more light on how the batteries lose performance over time, and could challenge previous assumptions of scientists working to develop batteries with longer lifetimes.

Bridging the gap between battery and supercapacitor

By engineering the structure of a hard carbon electrode, scientists at the CIC energIGUNE research center have created an ‘ultrafast battery’ which has been shown to combine the energy density of a lithium device with the fast discharge times normally associated with supercapacitors.

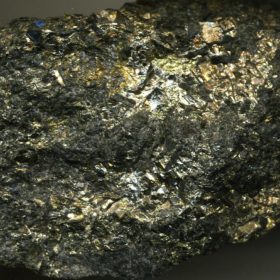

‘Investment in nickel production needs to happen now’

Rather than helping electric vehicle take-up by driving down costs to parity with traditional engines, the low price of nickel at the moment is deterring investors and could cause a supply shortage that holds back electromobility in a few years’ time.