Keep your solar cells dry

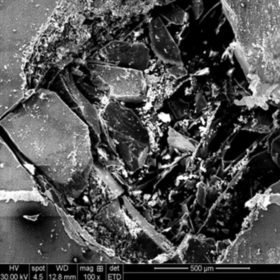

Scientists in Norway used various imaging and characterization techniques to analyze the cells and other components of silicon PV modules that had been installed in the field for more than 10 years. The group’s aim was to isolate the role of moisture in various mechanisms that cause performance loss over time, and to understand how these mechanisms progress over long-term installation in real outdoor conditions.

Key takeways from SiliconPV 2023

The annual SiliconPV Conference came to TU Delft in the Netherlands last week and offered an important health check for the science and technology behind solar energy. pv magazine was on site to hear the latest from researchers reaching for higher efficiency through tandem cells and other innovations, and working to cut down solar technology’s consumption of rare and expensive materials.

Putting bifacial modules to the test

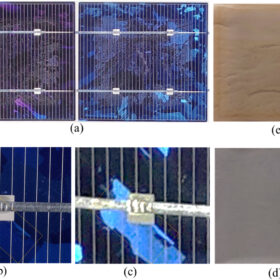

US scientists recently put different bifacial solar cells and modules through a series of tests at elevated temperature, humidity, voltage and mechanical stress levels. The tests revealed a range of light-induced and potential-induced degradation mechanisms that modules will likely suffer in the field.

Quantifying loss-mitigating effects of PV warranty insurance

German consultancy VDE Renewables and global reinsurer Munich Re have outlined an approach to quantify the impact of risk mitigation measures applied to PV projects, as well as the advantages that may be derived by relying on an insurance solution. Risk mitigation expert Ulrike Jahn has spoken with pv magazine on how the new approach was shaped and what kind of performance issues should be taken into account by PV asset owners.

Multiple effects of potential-induced degradation on solar module performance

UK researchers have analyzed the multiple effects of PID on 28 modules at an outdoor testing field. The novel approach considered all multiple PID effects through a comprehensive analysis, which included power losses, hotspots, mm-level defects, and the performance ratio.

Behind PID in bifacial solar cells

New research from Germany outlines mechanisms behind a form of potential-induced degradation specifically affecting the rear side of bifacial solar cells. Results suggest that the issue may be more complex than previously thought; and avoiding irreversible damage to cells in the field will require a rethink of testing standards.

When does revamping pay off?

With projects in many PV markets aging past the 10-year mark – with major leaps in technology having occurred in that time – revamping is a popular topic among asset owners. pv magazine spoke with Asier Ukar, general manager of the Spanish subsidiary of German engineering company PI Berlin, to uncover the benefits of revamping PV projects with new components and also to examine the challenges and risks involved.

The weekend read: Bifacial adoption spurs rethink on PID

PV systems are unique among electronic devices, as they are expected to survive outdoors for at least 25 to 30 years. This makes module and system quality one of the cornerstones of guaranteed returns on investment. Potential-induced degradation (PID) is a critical failure mode with a potentially high financial impact. New research from imec and Hasselt University looks at the damaging impact that PID can have on bifacial technology, writes Michaël Daenen, a professor at EnergyVille and Hasselt University.

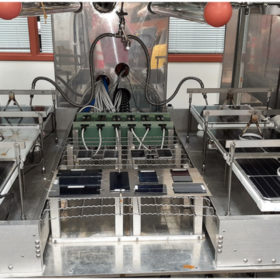

Foil method for PID test misleading if only one side of bifacial module is stressed

Results from PID stress tests can be misleading when bifacial PV modules are PID-stressed from just one side using the foil method in IEC TS 62804, according to a new study by Belgian researchers. An unintended electric field arises between the non-stressed side of the cell and the grounded interior of the climate chamber, which may have the undesired effect of causing additional PID stress.

Discussion on performance ratio as a KPI for service providers

The performance ratio of an installation is stable, yet the yield and the revenues drop significantly. A U.K. case study shows that faults can compensate for performance ratio value, meaning this value is not always a good key performance indicator on its own. This issue will be discussed during the upcoming asset management session at the pv magazine virtual roundtable Europe 2020.