Putting polyvinylidene-fluoride backsheets to the test

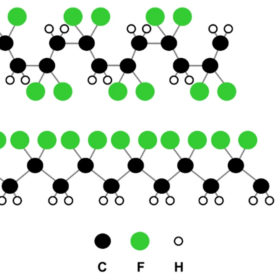

US scientists tested PV modules built with backsheets and polyvinylidene-fluoride (PVDF) layers, to replicate the degradation the material has suffered in the field of accelerated testing. By exposing the modules to multiple stresses, they were able to cause degradation in the backsheet materials. Though this did not closely match what has been seen in the field, such testing can be useful in identifying potential weaknesses.

Coveme: Pushing for a greener solar industry with emphasis on material innovation

Separating backsheets from solar PV modules is one of the most challenging issues for module recycling, because of the glues involved. Given the difficulties in pulling apart the layers, which are typically made of virgin plastic, they are usually burned. However, there are some industry players taking steps to improve the design, recyclability and reusability of backsheets. One of them is Italy-based Coveme, which recently partnered with pv magazine’s UP Initiative. In the following interview, CEO Amedeo Maccolini explains what the company is doing to step UP its sustainability game.