Researchers from the University of Queensland and Brisbane-based Graphene Manufacturing Group (GMG) are teaming up to develop faster-charging, more sustainable battery prototypes with lifespans three times the length of current lithium-ion batteries.

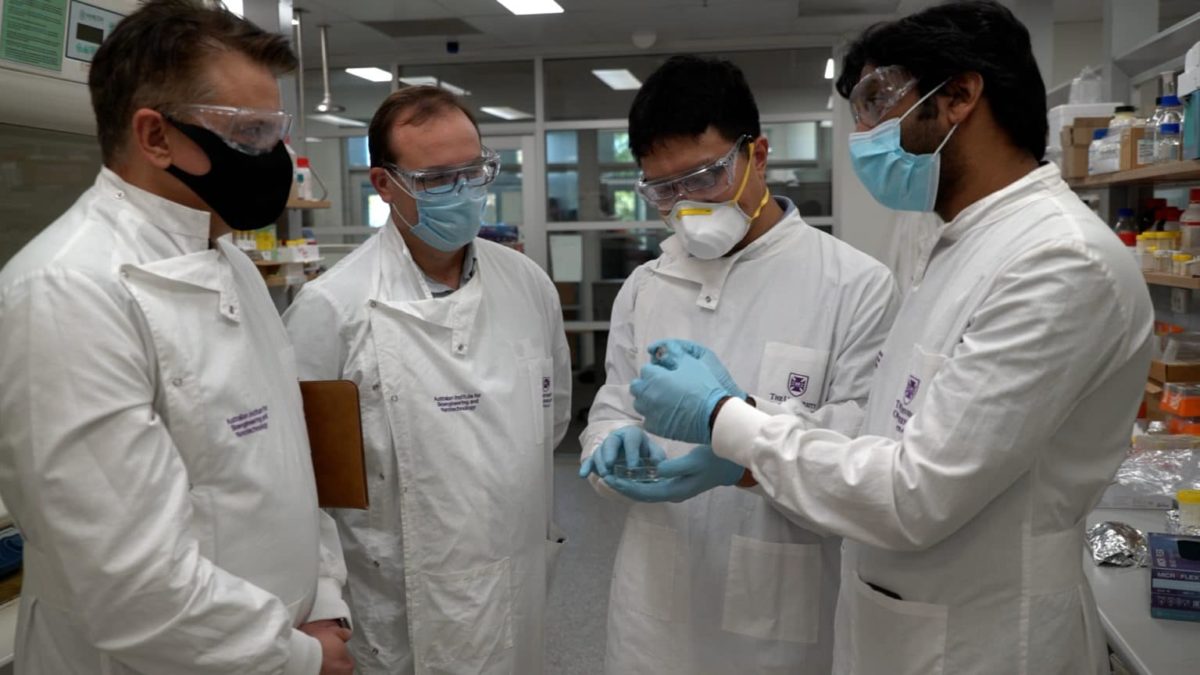

GMG, which was recently listed on the TSX Venture Exchange in Canada, has reached a research agreement with scientists from the University of Queensland’s Australian Institute for Bioengineering and Nanotechnology (AIBN) to build batteries for anything from watches to grid storage and everything in between, including phones, laptops, and electric vehicles.

The University of Queensland technology, which sees an aluminum ion battery paired with graphene electrodes, was designed by Professor Michael Yu, Xiaodan Huang and postdoctoral student Yueqi Kong as a way to make graphene into more efficient electrodes for powering batteries. The technology has already been patented and licensed by UniQuest, the University of Queensland's commercialization company.

Graphene is the wonder material of the age. It's the thinnest and strongest material known to science, and, if that wasn’t enough, it is also a great conductor of electricity – better even than copper. Or at least, it would be the wonder material of the age if the so-called “graphene revolution” promised less and delivered more.

It was more than a decade ago that scientists from the University of Manchester won the Nobel Prize for Physics thanks to some simple tape that proved to be a breakthrough in extracting graphene from everyday graphite.

In essence, graphene is just good old carbon, but it is tessellated in such a way to produce a bogglingly strong bond between atoms. Of course, like anything with so much promise and hype, the graphene revolution has taken longer than expected, but that is only because people don’t have much patience for the things they’ve been promised, especially when it is something as potentially ubiquitous as graphene.

Nevertheless, the University of Queensland and GMG are not the only parties making progress. In March, scientists at China’s Dalian University of Technology and the University of Nebraska in the United States collaborated to fabricate a battery consisting of a pure aluminum anode, a graphene cathode, and an organic electrolyte. The batteries are described in “Ultra-fast charging in aluminium-ion batteries: electric double layers on active anode,” which was recently published in Nature Communications.

Popular content

Back in 2019, scientists at the Royal Melbourne Institute of Technology (RMIT) demonstrated a laser printing process that enables graphene supercapacitors to be embedded directly onto textiles, creating a fabric that can store energy and be integrated with a solar cell and used to power smart fabric applications.

Graphene batteries

“Testing showed rechargeable graphene aluminium ion batteries had a battery life of up to three times that of current leading lithium-ion batteries,” said AIBN Director Professor Alan Rowan. “And higher power density meant they charged up to 70 times faster.”

AIBN has been working hard on the technology for several years, and the research team is excited to be shifting into a commercial prototype development stage, especially as the promise on the cards is more efficient and greener batteries.

“The batteries are rechargeable for a larger number of cycles without deteriorating performance and are easier to recycle, reducing potential for harmful metals to leak into the environment,” said Rowan.

UniQuest CEO Dean Moss said he believes aluminum ion batteries with graphene electrodes “could transform the existing rechargeable battery market. Lithium-ion batteries demand the extraction of rare earth materials using large amounts of water and are processed with chemicals that can potentially harm the environment.”

GMG CEO Craig Nicol agrees, noting that the possibility for the energy storage market included far-reaching benefits in safety, efficiency, sustainability. He points to the ability of aluminum ion batteries “to use local raw materials to manufacture battery cells at a competitive cost to replace imported lithium-ion cells is a massive opportunity for GMG and Australia to reduce supply chain risks and create local jobs.”

University of Queensland scientists were awarded a AUD 390,000 ($303,600) grant over three years from the Australian Research Council’s Linkage Project in 2020 to develop graphene aluminum ion technology.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

No mention of the energy density (as distinct from power density) relative to lithium ion. Also, would a solid state version be possible and preferable?

With recharge rates of 70 times faster than LiPO you could in theory stop more often for quick charge. Say you only got 1/4 the energy density you might only get 100km out of your tesla, but recharge in say 5 min to 100%, good enough for 80% of your daily drive as most do less then 40km a fay.

PROTON EXCHANGE MEMBRANES. ARE KEY TO UNIVERSAL BATTERY ? 2ND PART IS THE ON GOING RECHARGE SYTEM. Blur gas .. which I know . Generator effects as a co.plement source .

.

As I understand it, from an episode of the Skeptics Guide to the Galaxy, the energy density of this type of battery is about 3x that of Lithium Ion.

So could you have a structural aluminium vehicle body, that safely stored energy?

As long as you don’t mind turning some structure to ions as you drive, that sounds fine. It might be worth working up against the structural battery work with all that tough graphene holding the Al salts.

Graphene aluminium ion batteries present as a gob-smacking advance in battery energy storage. EV vehicles will celebrate this development, and fossil fuel vehicles prepare for your imminent funeral.

Great stuff University of Queensland.

what about its application for large utility scale storage for the grid?

Should get rid of a lot of poisonous lithium cobalt batteries and get rid of range anxiety and hopefully be a lot cheaper which will really open up the car market to the vast majority of us

gmg.v