Proper recycling strategies for perovskite solar modules would improve their carbon footprint and their overall energy payback times, but such module technology is still far from reaching full commercial maturity, according to researchers from Cornell University.

The scientists have tried to show that recycling strategies could improve sustainability and energy payback times for PV modules, given the current pace of technological development. Energy payback refers to the time it takes for solar panels to generate the same amount of energy that was used to manufacture them.

The research team said that most scientists are currently working on perovskite cell performance and the well-known issue of thermal stability, which needs to be improved if the technology is to reach mass production.

“However, the perovskite modules' energy packback time is less relevant to the stability issue,” researcher Fengqi You told pv magazine. “We found perovskite modules typically last longer than their energy payback time.”

According to the research group, proper recycling strategies could substantially improve the environmental performance of new perovskite solar cells.

“We had taken lead into account in our analysis,” You said. “It is very important to consider it due to the health and environmental concerns, but we should also keep other toxic components in mind in this process.”

In the proposed approach, lead is not expected to be recycled, but rather “treated” through selective dissolution, he noted.

“We are aware of the importance of further developing technologies to better treat and recycle lead from the perovskite cells and we have an ongoing project on both technology development and systems analysis looking into this issue,” You said.

Popular content

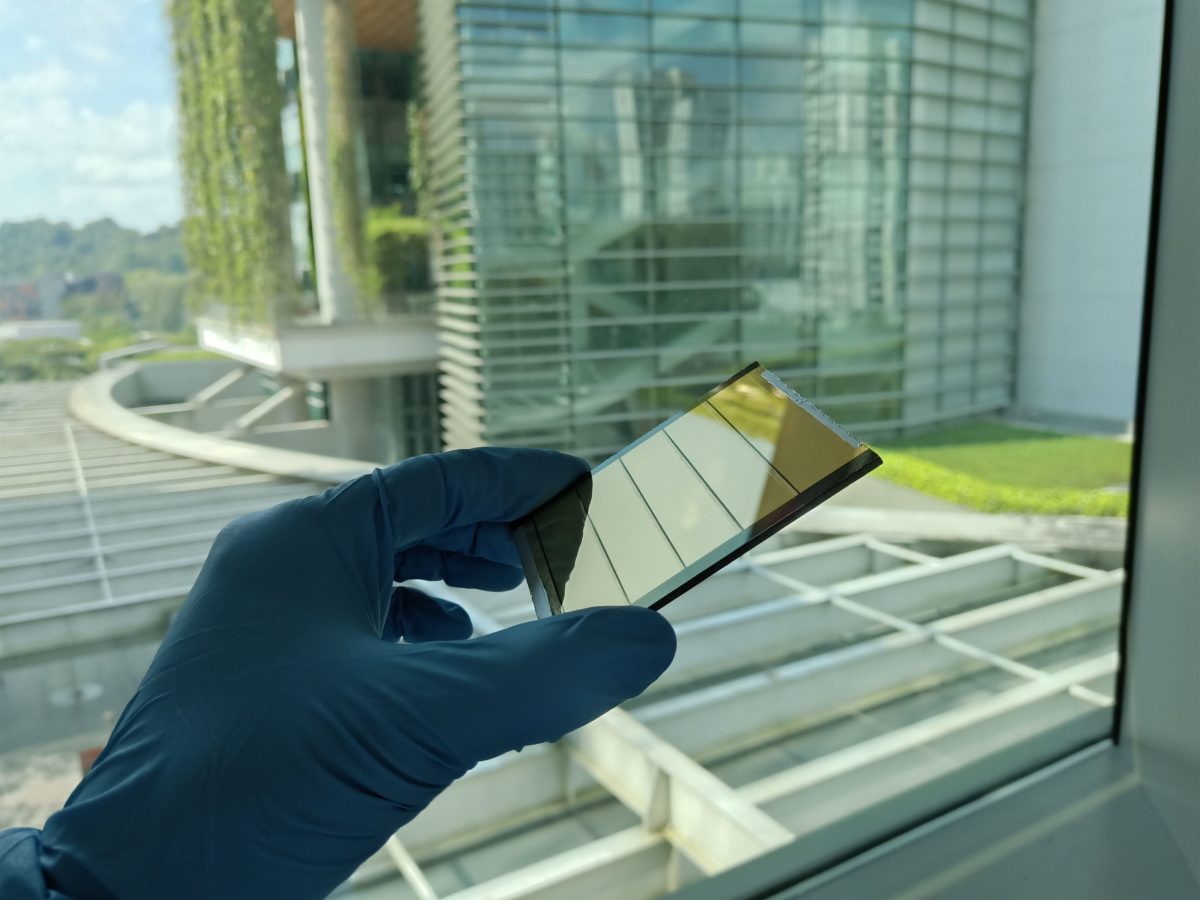

The academics made a distinction between laboratory-scale modules based on niche materials and panel prototypes that may be close to industrial production. They identified six device architectures and performed life cycle assessments (LCAs) for both material replacement and recycling. The six categories include: panels with electron transport layer (ETL) based on Lanthanum (La)-doped BaSnO3 (LBSO) perovskite; modules with charge transport layers made of metal oxide; devices fabricated with mixed cation halide perovskite; defect-engineered panels; products fabricated with a a Tin(IV) oxide (SnO2) layer; and semi-transparent modules.

According to the analysis, recycled perovskite solar cells could offer 72.6% lower primary energy consumption and a 71.2% reduction in carbon footprints. The best recycled perovskite cell architecture could see an energy payback time of about one month, with a carbon footprint as low as 13.4 grams of carbon dioxide equivalent output per kWh of electricity produced, the research group claimed.

“Without recycling, the energy payback time and carbon footprint of new perovskite solar cells show a range of 70 days to 13 months, and 27.5 to 158.0 grams of carbon dioxide equivalent throughout their life cycles,” they said.

These values compare to an energy payback period of 1.3 to 2.4 years for crystalline silicon modules. Their initial carbon footprint was estimated at 22.1 grams to 38.1 grams of carbon dioxide equivalent emissions per kilowatt-hour of output.

“Recycling makes perovskites outcompete all other rivals,” said researcher Xueyu Tian.

The researchers presented their findings in “Life cycle assessment of recycling strategies for perovskite photovoltaic modules,” which was recently published in Nature Sustainability.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.