Heterojunction (HJT) is among the most promising routes to higher efficiencies in silicon PV. While HJT modules are already in production from a few manufacturers, there is plenty of potential to push their efficiency higher.

Chinese manufacturer Longi Solar earlier this year set a record for HJT cell efficiency at 26.3%, and Australian startup SunDrive pushed efficiency for a commercial-sized to 25.54% back in September. Cell efficiencies for most HJT cells in mass production, however, remain around the 23-24% mark.

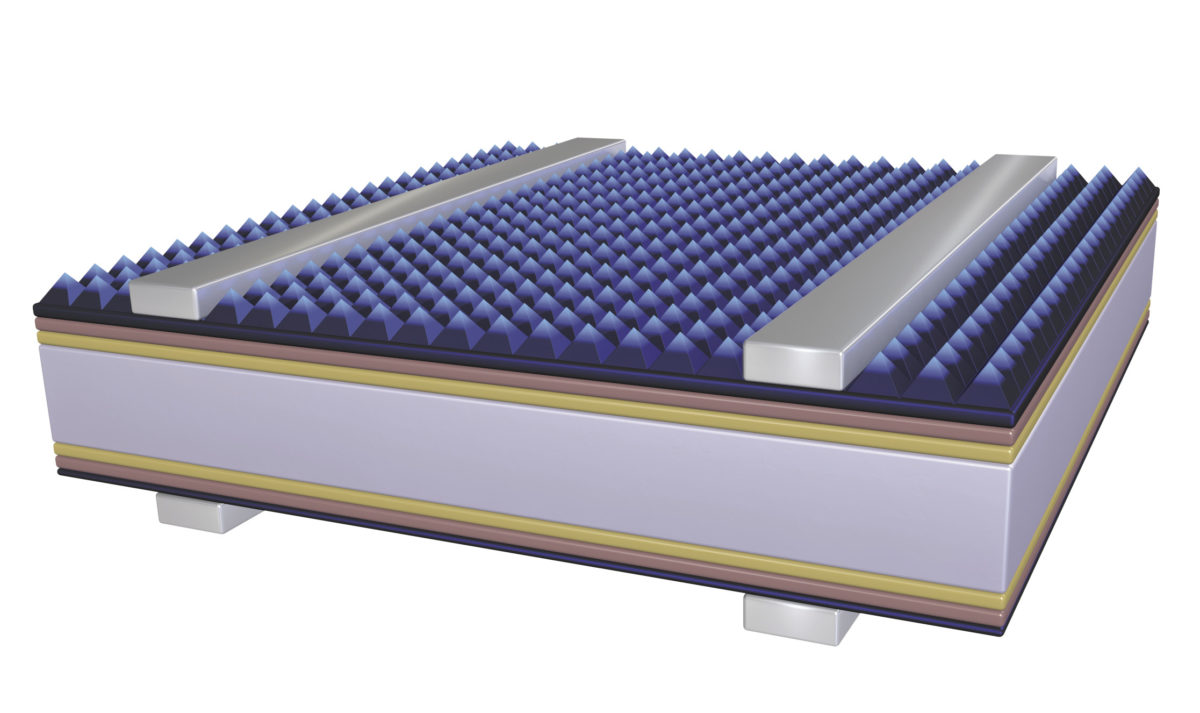

Scientists led by Germany’s Forschungszentrum Jülich analyzed the mechanisms leading to performance losses in an HJT cell, and identified several potential new routes to improved efficiency. And they were able to demonstrate these routes in action, improving the efficiency of an M2-sized HJT cell from 23.55% to 24.51% through the use of a two-layer structure of amorphous silicon and the addition of magnesium fluoride as an anti-reflective coating. Their work is described in full in the paper A route towards high-efficiency silicon heterojunction solar cells, published in Progress in Photovoltaics.

Rear side optimizations

The group noted that losses in the cell current were primarily caused by reflection, light trapping and parasitic absorption, while transport between the silicon layers and the transparent electrode was the source of losses in fill factor. Many common strategies to reduce parasitic absorption, they note, are in contradiction with efforts to reduce the series resistance.

Popular content

In looking for ways to avoid this contradiction, the group focused on the rear side of the cell. They divided the amorphous silicon layer into two parts, with a porous first layer and a dense second layer. This was shown to reduce resistance losses between the layers on the rear side, and improve the cell’s fill factor. Secondly, they applied a layer of magnesium fluoride between the transparent conductive oxide and back reflector, which reduced absorption and improved the current in the cell.

In their analysis of the loss mechanisms, the group also identified several other possible routes to improvement, with possibilities including more transparent, wide bandgap window layers, or further optimizations to the transparent conductive oxide layer, taking into account both optical and electrical effects.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.