In the never-ending pursuit of cost reduction, electroplating of PV cells has been considered for some time by producers as a potential replacement technology for screen printing. However, major progress with print processes resulting in finer metallization lines and reduced silver usage has meant that electroplating has not gained major traction with cell producers. That appears to be beginning to change, with some equipment and material suppliers making progress with plating processes, attracting considerable interest.

One indication of this shift is a deal announced today, and signed during the 2017 SNEC in China in April, which will see Germany equipment supplier RENA collaborate with Chinese producer Aiko Solar on the electroplating of cells. In announcing the collaboration today, the two companies say that the electroplating process can deliver a cost reduction per watt of around US$0.01, or around 15%.

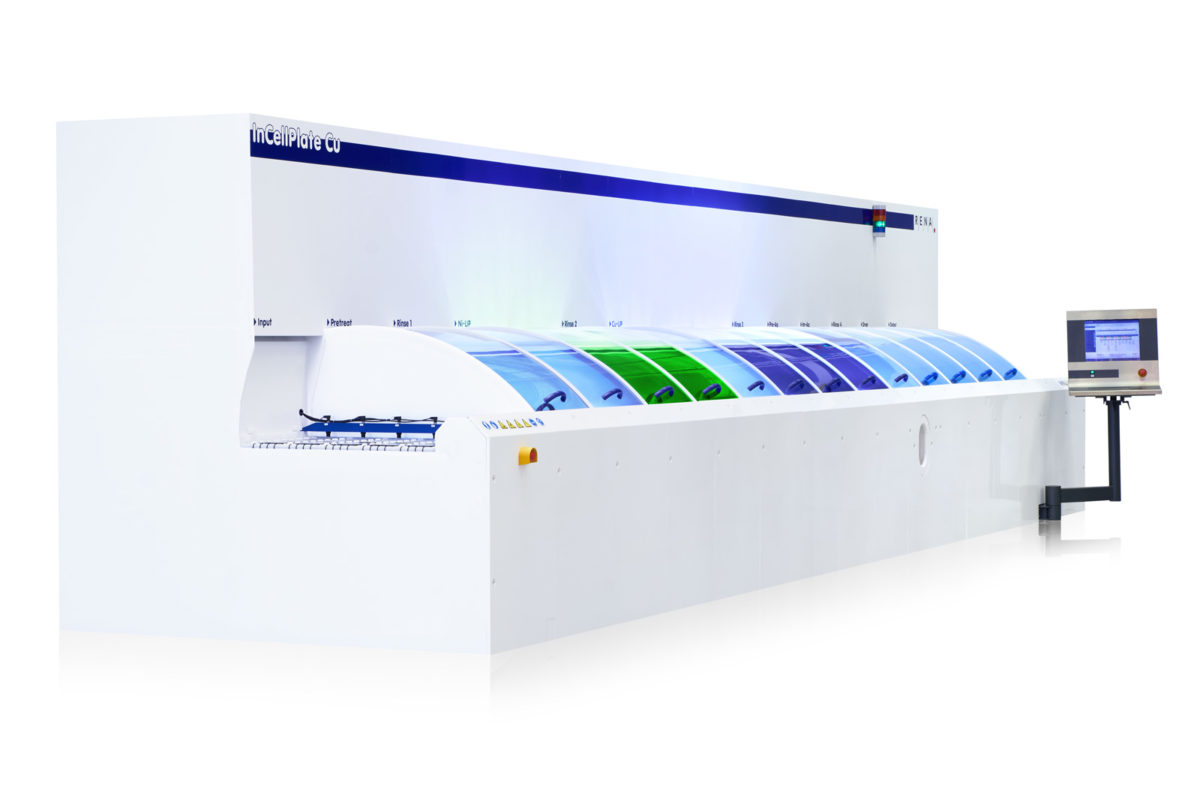

“The plating technology using the ‘Rena InCellPlate' will help us to drive down the cost as we can replace the screen-printed front side silver electrodes,” said Aiko Chairman Chen Gang in a statement. “This will be a major cost saving.”

Rena has collaborated with copper material supplier MacDermid Enthone, and laser supplier InnoLas on the electroplating process. It was recognized by pv magazine's independent jury as the co-winner of the 2017 Technology Highlights award, earlier this year during the SNEC event.

Popular content

Aiko produces both multi and monocrystalline PERC PV cells, including bifacial products. Rena has supplied alkaline texturing, Rena BatchTex, and edge isolation, Rena InOxide+, equipment to Aiko for its monocrystalline cell production lines.

Aiko has achieved efficiencies of 21.5% on mono PERC cells and has achieved a bifaciality of over 70%. The Chinese producer says that the Rena wet chemistry platforms allow it to meet the cell surface requirements of a variety of cell concepts.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.