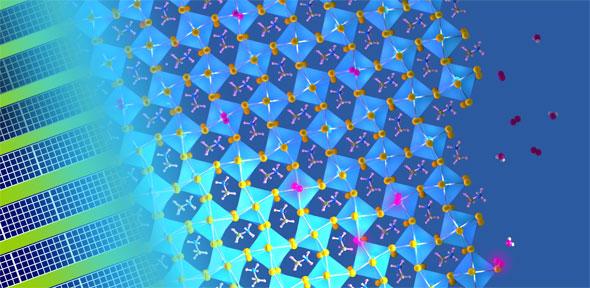

A joint team of researchers from Oxford, Cambridge and Bath Universities in the UK, the Massachusetts Institute of Technology and TU Delft in the Netherlands have made a discovery which could accelerate the development of viable perovskite solar cells.

The low-cost/high efficiency potential of perovskites has been well known for years now, but material defects and degradation have put major roadblocks in the technology’s development.

“In perovskite solar cells and LEDs, you tend to lose a lot of efficiency through defects,” explains lead researcher Sam Stranks of Cambridge University’s Cavendish Laboratory. “We want to know the origins of the defects, so we can eliminate them and make perovskites more efficient.”

The research, published in the inaugural edition of scientific journal Joule draws on the team’s previous discovery, which found that perovskite defects could be healed by light, but only temporarily. Now, the project has come a step further, and the researchers have discovered a method which makes the healing effect more permanent.

Popular content

The team created a perovskite device, production of which it says would be compatible with scalable roll-to-roll processes. Before completing the device, however, they exposed it to light, oxygen and humidity for 30 minutes, and then deposited the remaining layers to complete the device.

The application of light, and just the right level of humidity, caused electrons to bond with oxygen and form a superoxide, which could prevent defects from hindering electrons. The presence of humidity converted the perovskite surface into a protective shell, which removes defects from the surface and locks in the superoxide, making the healing effect last much longer.

“It’s counter-intuitive, but applying humidity and light makes perovskite solar cells more luminescent, a property which is extremely important if you want efficient solar cells,” continues Stranks. “We’ve seen an increase in luminescence efficiency from 1% to 89%, and we think we could get all the way to 100%m which means we could have no voltage loss – but there is still a lot of work to be done.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.