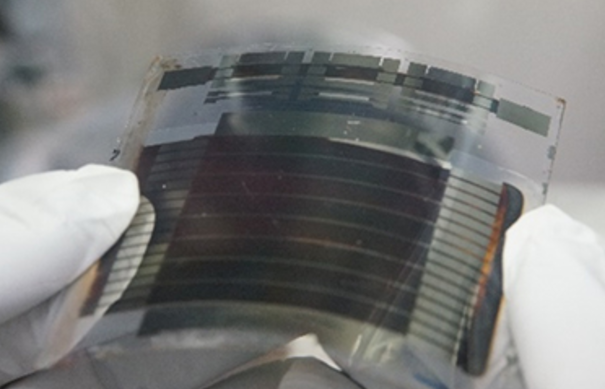

It reached a conversion rate of 10.5% for its 5X5cm film-based perovskite solar cell mini-modules by utilizing a new printing process. The company says its advancements will also drive cost reductions for flexible solar panels, particularly for use in building-integrated PV (BIPV) applications. It achieved its results under a research program supported by the New Energy and Industrial Technology Development Organization (NEDO).

The Tokyo-based group vowed to push forward with its R&D efforts to achieve efficiency rates that surpass those of crystalline silicon PV cells. It aims to eventually match baseload power generation costs in Japan by generating electricity for JPY 7 ($0.06)/kWh.

“Perovskite solar cells offer the promise of high conversion efficiency allied with reduced module costs, as they can be fabricated by printing,” it said in an online statement. “Having demonstrated the possibility of increasing area and efficiency of a film-based module, and achieving a conversion efficiency of over 10%, Toshiba will now focus on increasing the module size and conversion efficiency, through measures including changing the composition of the perovskite material and by process improvements.”

The company says it managed to expand the size of its cells and ramp up energy conversion rates by creating the 5X5cm cells. Its fabrication process for film-based perovskite solar cells involves using a film substrate and scribe method drawn from the production of organic thin-film solar cell modules. Its flexible film substrate allows roll-to-roll fabrication, which brings costs down.

However, the company acknowledged the difficulty of developing big, uniform perovskite polycrystalline layers. It also noted how the scribe process is not suitable for removing layers on top of electrodes, which drives up resistance between cells and drags down conversion efficiency. This is an obstacle to fabricating modules formed on a film substrate, it said.

Popular content

Toshiba’s printing technology for the production of film-based perovskite solar cell modules involves forming the substrate with a resin film, such as polyethylene terephthalate. It uses a planar inverted structure that can be produced at a temperature below 150C for the cell structure. The company managed to form a uniform thin layer of methylammonium lead iodide by utilizing a meniscus printing technology that it developed by conducting research on organic thin film solar cells. It said that this improves the efficiency of panels by lowering the degree to which the cells vary from each other.

The company also ramped up energy conversion efficiency by cutting the resistance between cells to the same level as with a glass substrate. It did so by optimizing blade pressure throughout the scribe process, but also by selecting materials that remove the layer that covers the electrodes, even with weak blade pressure. In addition, it said that it achieved the 10.5% conversion efficiency partly because the indium tin oxide transparent electrode that it developed for the resin substrate offered lower sheet resistance.

Last week, researchers from the University of Cambridge and Italy’s Politecnico di Milano reported that they had set a time limit for ultrafast perovskite solar cells and identified the speeds at which cells would have to operate to ramp up efficiency. And earlier this month, researchers from Oxford, Cambridge and Bath Universities in the U.K. — in cooperation with the Massachusetts Institute of Technology and TU Delft in the Netherlands — revealed that they had discovered that defects in crystalline perovskite structures can be permanently healed via exposure to light and humidity.

NEDO — an industrial R&D entity under the Japanese government — works with major Japanese companies to achieve new technological breakthroughs in a wide range of fields. In August, it teamed up with Hitachi and Itochu to switch on a microgrid powered by a 1 MW PV array in western India. The project will test microgrid control technologies and the effectiveness of Japanese PV modules in the hot, dry conditions of Rajasthan.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.