A research group from the University of Luxembourg has conducted a study that is said to change 20-year old assumptions on the chemical processes of solar cell manufacturing.

According to the scientists, the addition of sodium to the light absorbing layer of the cell, which according to common belief is responsible for inhibiting the mixing of gallium and indium, may be realized through a different approach, and a “more demanding fabrication strategy.”

Under the current traditional concept of cell manufacturing, the addition of sodium is made after the growth process of the light absorbing layer is concluded.

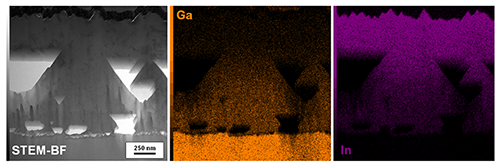

The Luxembourg researchers, instead, believe that if the absorber is made of only one grain, the addition of sodium can be made during the growth process. This, according to them, has the advantage of helping to homogenize the distribution of the elements.

“Instead, it is suggested that sodium promotes indium and gallium intragrain diffusion, while it hinders intergrain diffusion by segregating at grain boundaries,” the research team said.

Popular content

It added, “The deeper understanding of dopant-mediated atomic diffusion mechanisms should lead to more effective chemical and electrical passivation strategies, and more efficient solar cells.”

The authors of the report have concluded that the addition of sodium has the dual effect of homogenizing the elements inside each grain and of slowing down homogenization in the interplay between grains.

“This gives us the opportunity to rethink how we produce solar cells. In the future, these insights might lead to improvements in the manufacturing process,” said research coordinator, Philip Dale.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.