Cell microcracking is a major quality issue for the PV industry. Thanks to the weakness of silicon cell material, cracking can occur due to improper handling in module production, transport and installation, and significantly reduce a module’s power output before it is even installed.

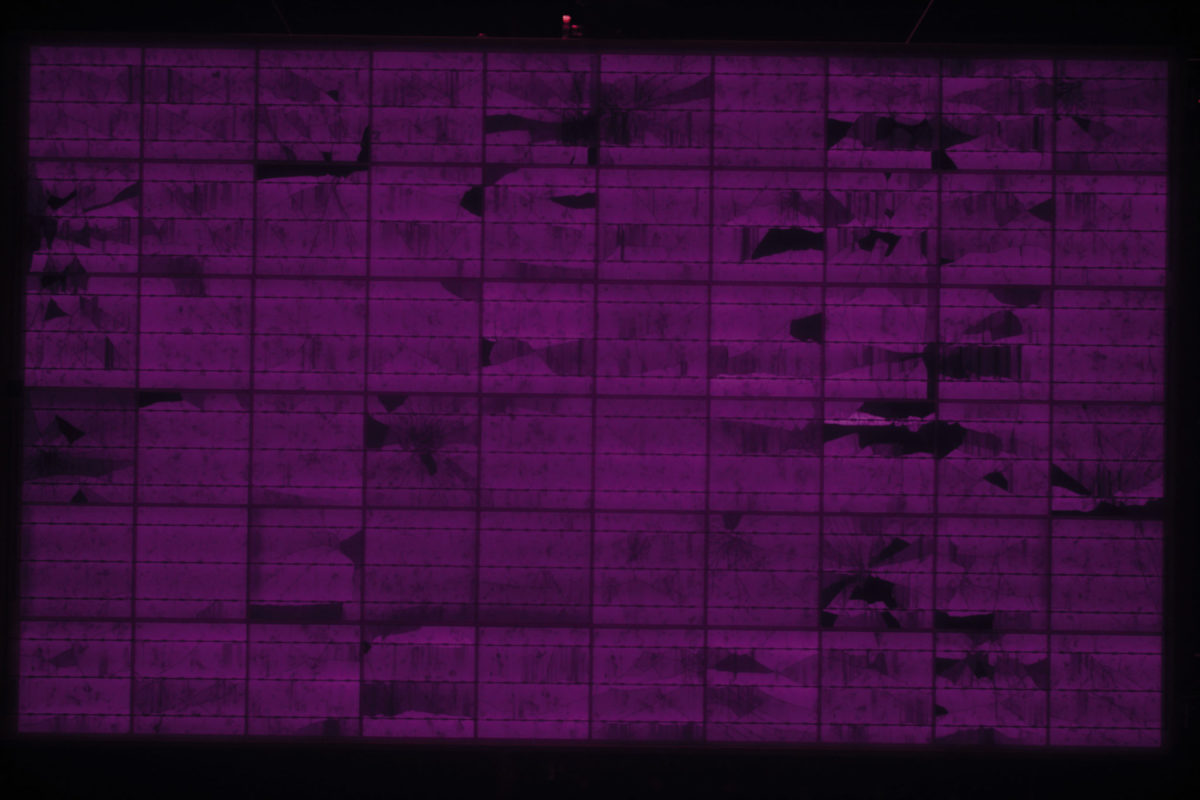

Scientists now propose new processes to be applied at the module level, where a pre-stressing technique is used to increase the residual compressive stresses present in the module. Cells which had this technique applied showed evidence of microcracks closing, and “dark” cracked sections in electroluminescence testing becoming active cell areas again.

The discovery was made by researchers on the EU funded PHYSIC project, led by the IMT School for Advanced Studies in Lucca, Italy. Rather than focusing on the cells themselves, the project’s approach took into account the whole module structure into which the cells are embedded.

“Careful analysis led to the discovery that exerting a weak residual compressive stress on solar cells after module manufacturing can increase electric conductivity around any cracks,” says Marco Paggi, the professor in charge of the PHYSIC project. “Due to these desirable residual stresses, cracks tend to close, letting electric current pass freely through them.”

Popular content

The project estimates the economic impact of microcracks – including repair/replacement costs and lost energy production – at €6 per kilowatt, per year. This would place overall annual losses well into three digit millions each year. “Neglecting material degradation issues can prove very harmful for the operation of PV modules,” says Paggi, “leading to electric power losses much higher than what is saved by focusing on increasing solar energy conversion efficiency.”

According the project’s outline on the EU’s Community Research and Development Information Service, the project has received a €149,000 grant from the EU, and includes plans for the founding of a startup company for fund raising and industrial exploitation of the idea.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Is it impractical to include a performance measurement of some form in the contract so no money until the panels produce certain amount of power into a defined dummy load per lumen of sunlight?