A team from the Okinawa Institute of Science and Technology (OIST) has published research it says could be the “key to moving perovskite solar cells to market”.

The research focuses on the electron transport layer. The team used tin dioxide (SnO2) instead of the more commonly used titanium dioxide for the layer, which was deposited using sputtering deposition – a common process already used in industry.

The team noted tin dioxide is already known as a viable replacement for titanium dioxide – which tends to react with the perovskite layer when exposed to sunlight, degrading the device – in perovskite cells, but stated it is the first group to successfully incorporate such an electron transport layer into a “large scale device”.

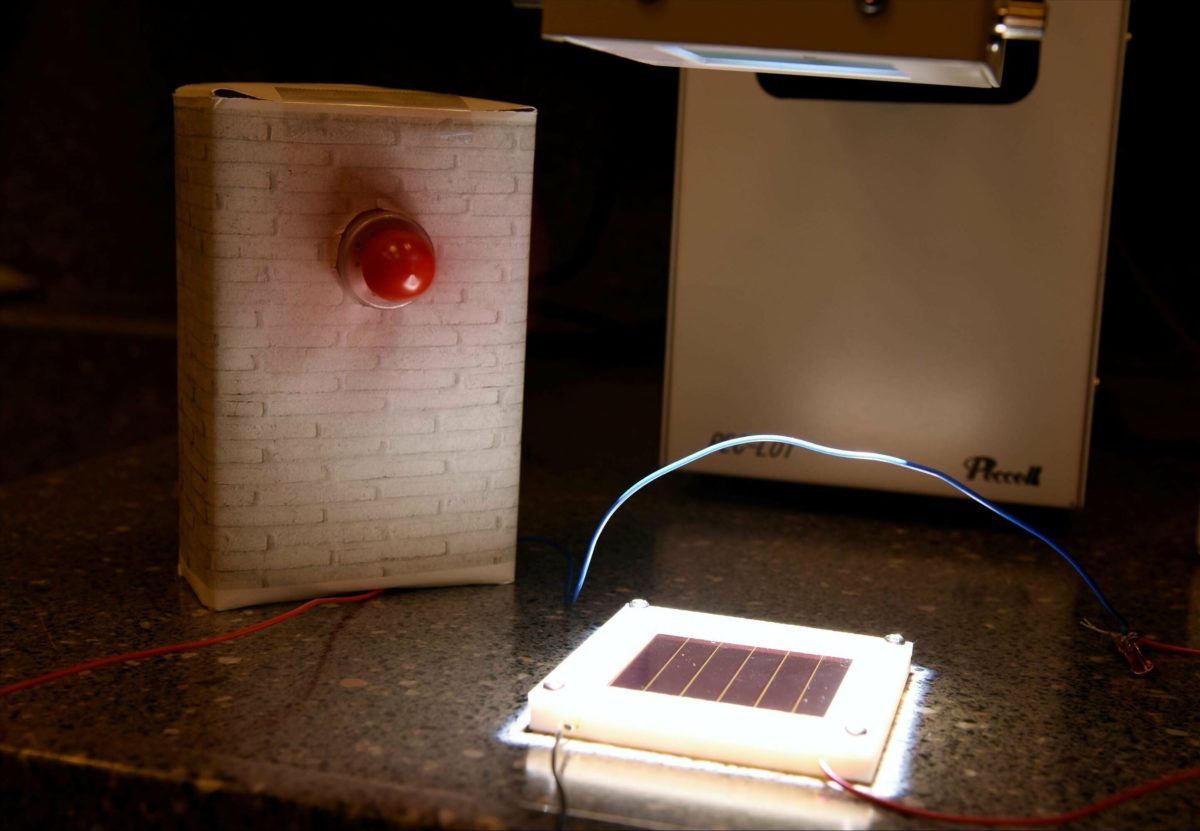

The result, described in the paper Scalable Fabrication of Stable High Efficiency Perovskite Solar Cells and Modules Utilizing Room Temperature Sputtered SnO2 Electron Transport Layer published in the Advanced Functional Materials journal, achieved a maximum efficiency of 20.2%. The team was also able to demonstrate a larger device that incorporated its SnO2 layer, creating a 5x5cm² module which had efficiency of more than 12% and an operational lifetime – defined as the point at which efficiency falls to 80% of the initial value – of 515 hours.

Popular content

Extended lifetime

According to OIST, the lifetimes demonstrated by the tin dioxide-based devices are more than three times those achieved on devices featuring a titanium dioxide electron transport layer. The researchers are also enthusiastic about the potential for commercialization of devices based on their technology, and said it represents “a crucial step forward towards meeting the current industry standard for perovskite solar cell efficiency”.

“We want to scale these devices up to a large size and though their efficiency is already reasonable, we want to push it further,” said Yabing Qi, lead author of the paper and a post-doctoral scholar in OIST’s Energy Materials and Surface Sciences unit. “We are optimistic that in the next few years this technology will be viable for commercialization.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Only 12% and 515 hours, that`s not much is it, i think i`ll stick to the panels i`ve got.

Paywalled Wiley journal. This is a downvote.