Researchers from the Queensland University of Technology have made a remarkable breakthrough with the development of an electrochemical process in which carbon dioxide is captured from the air and stored in water as a non-toxic calcium carbonate (chalk) in a renewably powered process that could also produce green hydrogen and decarbonize the cement industry.

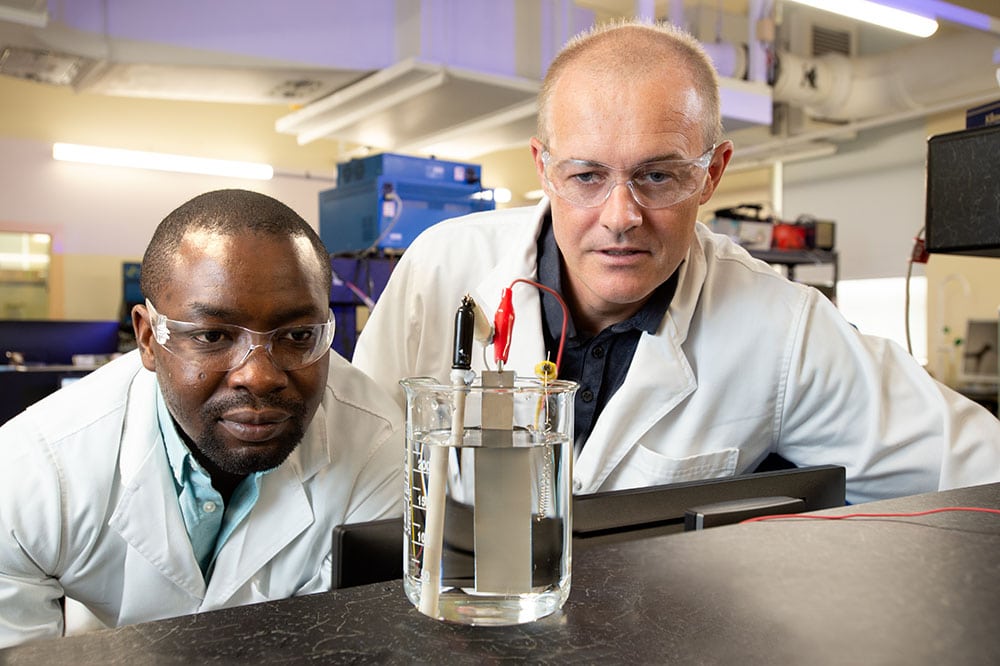

PhD researcher Olawale Oloye and Professor Anthony O’Mullane from the QUT Centre for Clean Energy Technologies and Practices developed the process of capturing and converting carbon dioxide through a mineralization approach that seems to produce a host of serendipitous by-products.

According to O’Mullane, the “process involves the capture of CO2 by its reaction with an alkaline solution produced on demand, to form solid carbonate products which can be used, for example, as construction materials, thereby keeping carbon dioxide out of the atmosphere. This can be done using a simple calcium source in water.”

It is also important to note that the QUT researchers used seawater instead of potable water, as potable water is too precious a resource for large-scale carbon capture, especially in Australia.

Popular content

“We found we could use seawater once it had been treated to remove sulphates. To do this we first precipitated calcium sulphate or gypsum, another building material, and then carried out the same process to successfully turn CO2 into calcium carbonate, thus providing proof of concept of a circular carbon economy,” O’Mullane said. “Next, the hydrogen evolution reaction during electrolysis ensured that the electrode was continually renewed to keep the electrochemical reaction going while also generating another valuable product, green hydrogen. This means if this electrolysis process is powered by renewable electricity, we are producing green hydrogen alongside the calcium carbonate (CaCO3).”

The process captures and stores carbon dioxide from the atmosphere, while also generating a green fuel source capable of decarbonizing pesky industrial sectors such as heavy transport, manufacturing, and the entire energy sector of export partners like Japan.

O’Mullane said the use of renewable energy to capture CO2 and create calcium carbonate may be needed in the cement industry, which is one of the tougher industries to decarbonize.

“We envision this technology would benefit emission-intensive industries such as the cement industry whose CO2 footprint is 7-10% of anthropogenic CO2 emissions,” said O’Mullane. “By coupling the mineralization process to produce CaCO3 from the emitted CO2 during the clinking step we could create a closed loop system and reduce a significant percentage of the CO2 involved in cement production.”

The scientists described their findings in “Electrochemical Capture and Storage of CO2 as Calcium Carbonate,” which was recently published in ChemSusChem.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.