Long-distance hydrogen interconnectors may become competitive with high-voltage electricity cables for the transport of energy, provided that the fuel interconnectors are longer than 350km and have a capacity of more than 1GW, when considering construction in 2050.

Those are the main conclusions of a study conducted by researchers at Durham University, in the U.K., in which the authors assessed the techno-economic potential of hydrogen interconnector systems (HIS'), by calculating the levelized cost of energy (LCOE) and the levelized cost of storage (LCOS) as the main parameters.

According to the paper, there are currently only 4,500km of hydrogen pipelines globally, which compares to over 160,000km of oil and gas pipelines. “Due to the lower energy density of hydrogen compared to methane, hydrogen pipelines require larger capacities than natural gas pipelines to transport the same amount of energy,” the scientists explained. “This would be achieved either through compressing the hydrogen to higher inlet pressures or designing pipelines with larger internal diameters.”

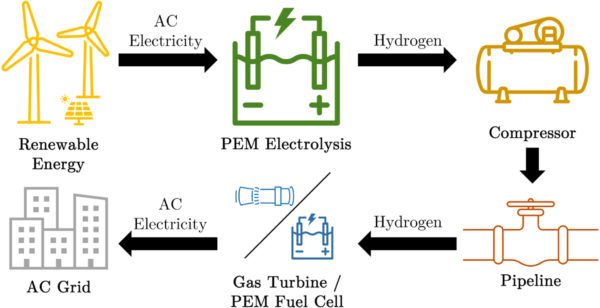

The modeling considered a system based on a polymer electrolyte membrane (PEM) electrolyzer plant requiring nine liters of feedstock water to produce 1kg of hydrogen; a pipeline made with API 5L Grade X52 carbon steel and with an internal diameter of 50-120cm; and PEM fuel cells (PEMFC) or hydrogen-fired gas turbines (H2GT), to re-convert hydrogen into electricity.

Image: Duhram University, Journal of Cleaner Production, Commons License CC BY 4.0, https://bit.ly/3KK5f2B

The LCOE of the HIS' was compared with that of a high voltage direct current (HVDC) transmission line for a base case of a 1,000MW, 100km system under “high,” “medium” and “low” scenarios based on construction years in 2020, 2025, 2030, and 2050. “The results show that the total cost of the HIS is highly sensitive to the cost of input electricity and [the] efficiency of the hydrogen-[to]-electricity or electricity-[to]-hydrogen conversion,” the British group stated. “The most cost-effective HIS uses a gas turbine at pipeline outlet for construction in 2020-2030, being replaced by a fuel cell combined with a direct current to alternating current converter in 2050.”

Popular content

For the proposed HIS system, the LCOE was found to range from $0.105-0.184/kWh for construction in 2020, and to be between $0.056 and $0.098/kWh for construction in 2050. “The main driver of the decrease in LCOE over time is the improvement in electrolyzer efficiency, which increases the total system efficiency from 32.4 to 48.4% in the case of the “medium” scenario, reducing the lifetime electricity demand by … 30%,” the paper reads.

From an LCOS perspective, the proposed HIS system provides cheaper stored energy than an HVDC system using long duration hydrogen storage, for construction from 2030, with the potential to become competitive in 2025. Its LCOS was estimated at $0.732/kWh in 2020, between $0.398 and $0.685/kWh in 2030, and $0.398/kWh in 2050.

“The HIS has significant advantages from a storage perspective, with an LCOS four times less than that of the HVDC system,” the academics explained. “This demonstrates the benefits of the HIS when used for large scale storage.”

Their findings can be found in the paper “The techno-economics potential of hydrogen interconnectors for electrical energy transmission and storage,” which was recently published in the Journal of Cleaner Production.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

This is great clean technology for the future. Basically the routes of the proposed hydrogen lines can follow existing electrical transmission line corridors with minimal environmental damages as the corridors are already existing.