From pv magazine Spain

Solar cells are the main components of PV modules and the presence of defects inside them – such as cracks, fissures or faulty contacts – can affect their performance and contribute to power losses. Electroluminescence (EL) tests are an increasingly used tool, together with thermography tests, to check panels.

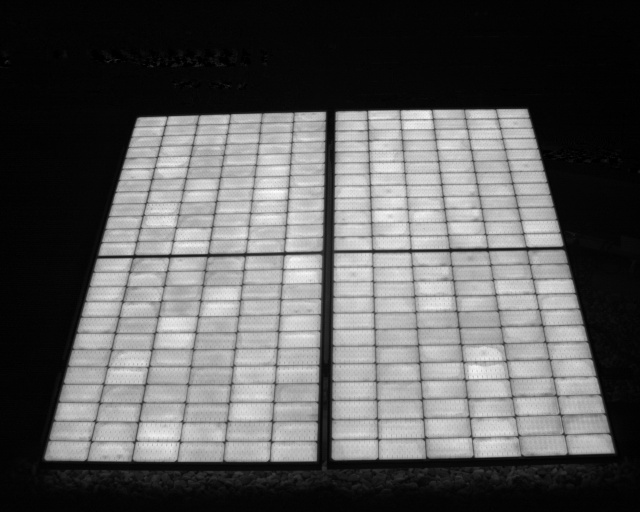

EL offers high-resolution images to provide useful information on the state of the cells, such as the quality of the busbar welding, for example. By visualizing a very wide range of defects, it is easier to assess the condition of solar panels.

However, the technology is not easy to apply. The need to polarize the modules to inject a current that produces the luminescence of the cells, the low intensity of the signal, and the high environmental noise make it necessary to work at night, when the solar panels are not generating electricity.

Spanish startup GdS Optronlab Group and Enertis Applus+ have developed a device based on the use of cameras that are sensitive to the near-infrared, which allows daytime electroluminescence measurements to be carried out, in solar radiation environments, without the need to disassemble panels.

The prototype incorporates software with a wide range of image capture and processing procedures. It can create images in different conditions (night and day) and in automated processes.

Popular content

The company said the results produce good signal-to-noise quality images, as during the day it is possible to obtain the signal emitted by the module, eliminating the light (or noise) generated by neighboring objects when receiving the natural light. Having a high signal-to-noise quality is particularly important when an electroluminescence image of sufficient quality is required to analyze the quality status of a module. In addition, the system is controlled by a micro PC and can be run on any Android mobile device.

The companies tested the prototype both in real operating conditions – in several PV plants, under different values of irradiation and cloud cover – and in a more controlled system, within a pilot plant in the laboratory. They said the results have shown that the prototype facilitates diurnal electroluminescence tests in an efficient way, optimizing the time of image acquisition.

Specifically, the system enables the simultaneous polarization of entire strings of modules, reducing the number of connections and disconnections and the probability of accidental errors. It has been possible to inspect up to 80 panels per hour in daytime electroluminescence with high-quality images, comparable to those obtained in laboratories. The results also pave the way for substantial improvements in the acquisition of nocturnal electroluminescence images, the companies claim.

They said the prototype has important operational advantages, such as the reduction of auxiliary elements and the presence of a wireless connection to facilitate mobility in difficult environments. This opens the door to massive electroluminescence tests in real operating conditions during the day.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.