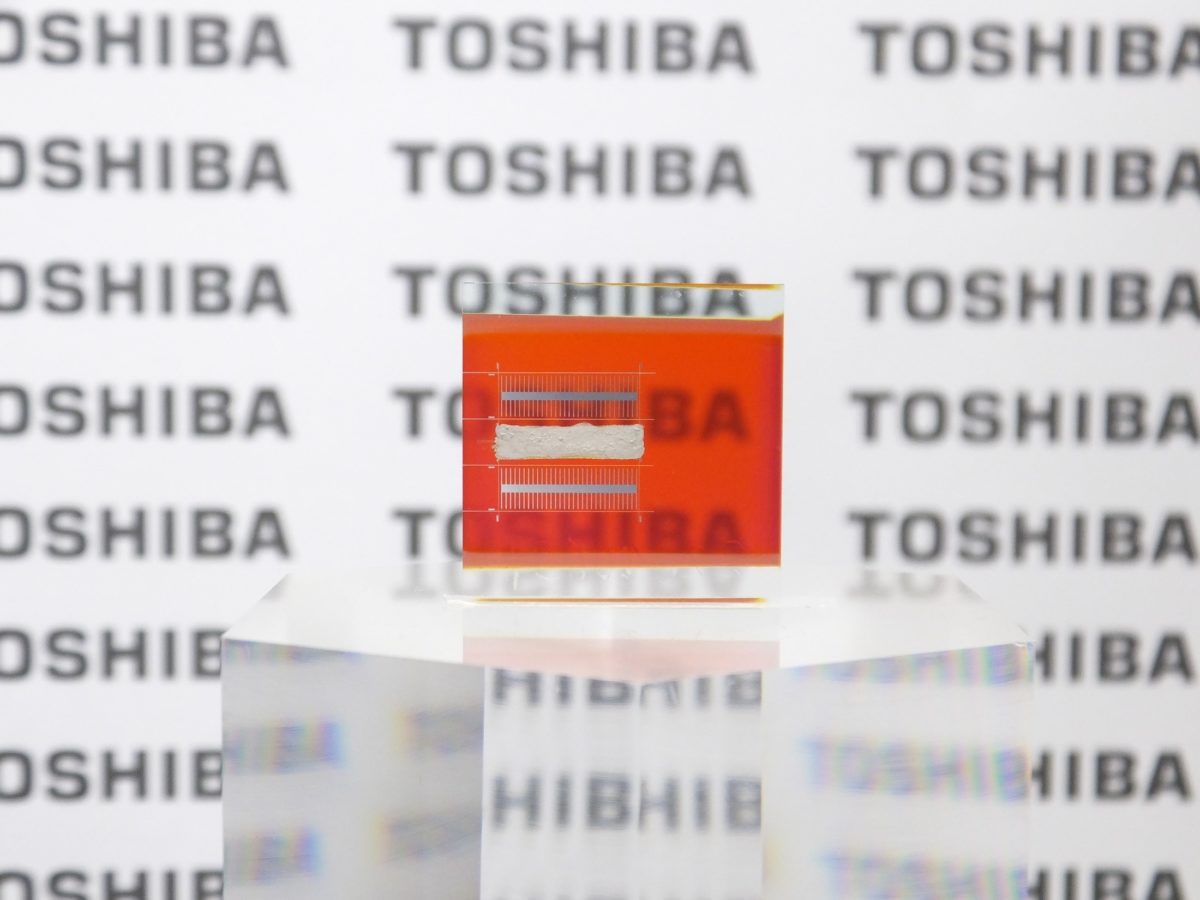

Toshiba has announced a new 9.5% power conversion efficiency rating for a transparent cuprous oxide (Cu2O) thin-film solar cell. This represents an improvement from the 8.4% result it achieved in December 2021. It claims to have now achieved the highest efficiency ever reported for any cell of this kind to date.

“The new cell is expected to provide a boost for the development of electrical vehicles that do not require plug-in charging, and to advance other mobility applications, such as high-altitude platform stations, telecom platforms in the stratosphere,” the Japanese electronics manufacturer said in a statement.

It achieved the record efficiency rating by enlarging the cell and suppressing carrier recombination at the edge of the cuprous oxide (Cu2O) generation layer, which usually causes generation efficiency degradation.

“We found that a larger cell size effectively suppresses photocarrier recombination,” said Kazushige Yamamoto, a fellow at Toshiba's Corporate R&D center. “Increasing the power generation area from the previous 3 mm2 x 3 mm2 to 10 mm2 x 3 mm2 produced a relative reduction in recombination in the edge of the cell. The resulting increase in photocurrent pushed the power conversation efficiency to 9.5%.”

Toshiba said that placing the Cu2O solar cell over a silicon (Si) cell with 25% efficiency could result in a Cu2O-Si tandem cell with a 28.5% efficiency. Such a tandem cell, charged only once, could power an EV for 37 km, according to tests performed by the company.

Popular content

Having already enlarged the previous cell’s size to 30 mm2, Toshiba is now working toward commercialization by further increasing this measure. Its goal is to achieve a 10% power conversion efficiency for a transparent cuprous oxide solar cell, and 30% efficiency for the Cu2O-Si tandem cell. To that end, it has developed a 40 mm2 prototype Cu2O cell which showed an efficiency of around 8%.

“The efficiency falloff in the larger cell is due to a less uniform layer,” the company said. “Toshiba continues to refine thin film deposition technology for uniform deposition over a larger area.”

Image: PRNewsfoto/Toshiba Corporation

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.