A research group from the Chinese Academy of Sciences has developed a new swelling process to separate glass and backsheets based on ethylene-vinyl acetate (EVA) from solar cells in end-of-life modules.

“Our swelling process is not violent and controllable,” said Wang Dong, the research's lead author. “It doesn't break the solar cells and ensures high-efficiency recycling rate of the cells and precious metals. Furthermore, it has a very low toxicity and the swelling agent can be recycled.”

In the paper “Recycling of solar cells from photovoltaic modules via an environmentally friendly and controllable swelling process by using dibasic ester,” published in Clean Technologies and Environmental Policies, the scientists explained that the process uses a dibasic ester (DBE), which is an ester of a dicarboxylic acid commonly used as lubricant, spin finish, and additive.

“DBE is a promising green solvent widely used in the coating industry that is a mixed ester composed of dimethyl succinate, dimethyl glutarate, and dimethyl adipate,” they said. “In addition, DBE has a boiling range of 196 C to 225 C and can dissolve most resins.”

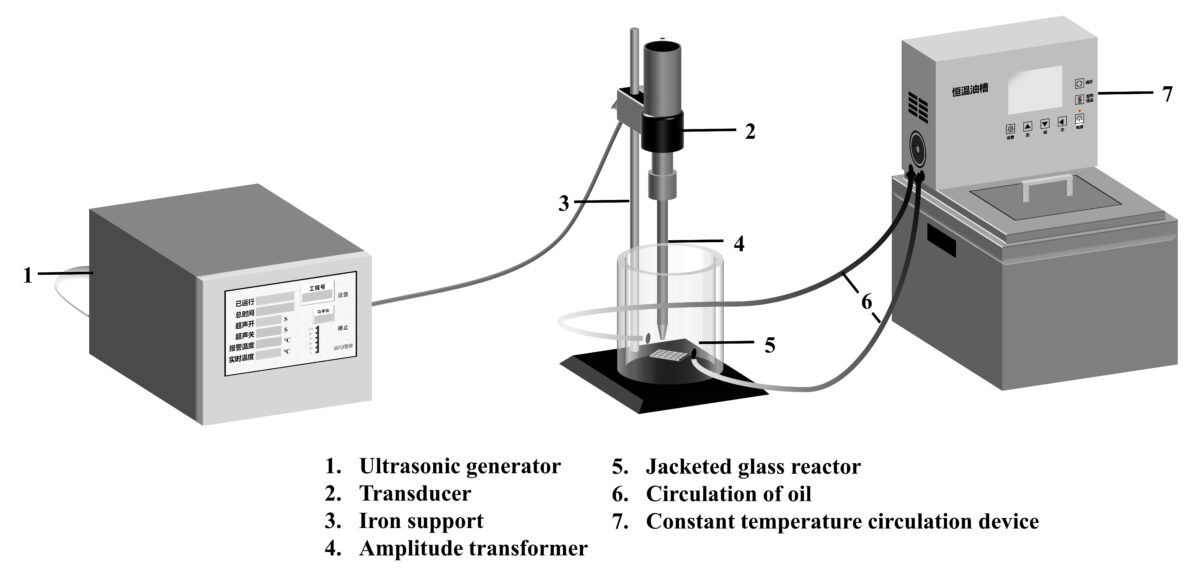

The DBE is claimed to penetrate into the glass-EVA gap effectively while preventing moisture in the air from entering the separation system to hydrolyze DBE. In the next step, an ultrasonic field is used to promote the separation of glass-EVA.

Popular content

“Then the separation system can be filtered to obtain a glass and (solar cell + EVA) composite. Finally, the mixture is sieved to obtain (solar cell + EVA), and the EVA can be eliminated by pyrolysis to sufficiently recover the solar cells,” the researchers continued. “In contrast to the direct thermal process, no fluoride is released during the EVA pyrolysis due to the prior removal of the backsheet.”

The group tested the novel technique on a Jinko 535 W solar module measuring 1,956 mm × 992 mm and weighing 22.5 kg, with the junction box and aluminum frame being removed in advance. It performed the glass-EVA separation in a glass reactor at a bottom diameter of 120 mm × 12.5 mm and a height of 195 mm × 20 mm.

Through these measurements, the scientists found that the low swelling of DBE resulted in fewer cracks compared to a swelling process based on commonly used O-dichlorobenzene. They also noted that the price of O-dichlorobenzene is between CNY 16,000 ($2.316) and CNY 18,000 per ton, while the cost of DBE is lower at between CNY 9,500 and CNY 10,600 per ton.

“In conclusion, using DBE to separate glass-EVA can keep the relative integrity of EVA to make resource recovery more manageable, and using DBE as a separation reagent has the advantages of low cost and green environmental protection,” Dong emphasized. “The detailed cost accounting, however, will be finalized this year after the scale-up test.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.