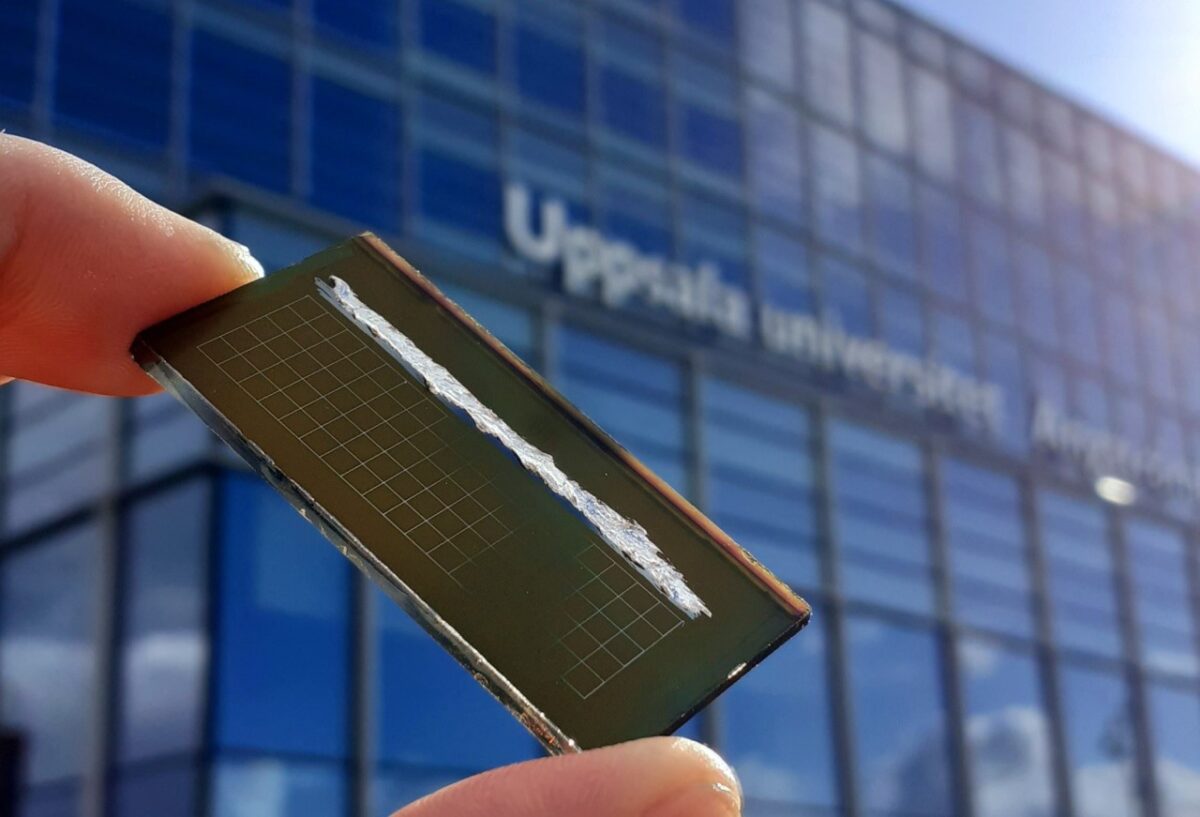

Researchers at Uppsala University in Sweden have fabricated a chalcopyrite (CuGaSe2 or CGSe) solar cell by using silver (Ag) to alloy the device absorber.

“The aim of our current EU-funded project Stable Inorganic TAndem (SITA) solar cells, is to make a wide-gap chalcopyrite top cell for tandem PV devices with silicon bottom cell,” researcher Jan Keller told pv magazine. “So, in the next step we need to transfer the process to transparent back contacts. We have shown the potential to make wide-gap chalcopyrite solar cells with slightly lower band gaps of about 1.45 eV on highly transparent back contacts in our earlier work.”

The use of silver alloying improves grain growth and crystal quality, while reducing detrimental defects and partly compensating for the low bandgap energy of the CuGaSe2 absorber. CuGaSe2 has band-gap energy of 1.7 eV and has thus far been used in solar cells with limited fill factor and open-circuit voltage.

“In addition to losses directly related to the CuGaSe2 layer itself, front interface recombination is supposed to be pronounced when a standard cadmium sulfide (CdS) buffer is used,” the scientists said, noting that they tested devices with CdS buffer layers and layers made of zinc tin oxide (ZTO) grown via atomic layer deposition (ALD).

The research team used a three-stage co-evaporation process to deposit the absorber alloyed with silver (ACGS) for several samples of solar cells.

“The carrier collection improves with Ag addition, higher deposition temperature, and toward stoichiometric absorber composition,” they said. “Light soaking increases the fill factor for most of the samples, potentially by mitigating internal transport barriers.”

Popular content

The champion cell the scientists fabricated was based on a ZTO buffer layer, with the device achieving a power conversion efficiency of 11.2%.

“This is the highest efficiency ever measured on an ACGS solar cell without an anti-reflecting coating,” they said. “Possible explanations for the beneficial effect of the light soaking may be the photodoping of the ZTO layer that would reduce the effective barrier height for electrons, or a redistribution of sodium at the heterojunction.”

The scientists said that they plan to use a transparent back contact (TBC) instead of one made of molybdenum (Mo) in the cell, due to its expected use in tandem devices.

They described the solar cell technology in “Silver Alloying in Highly Efficient CuGaSe2 Solar Cells with Different Buffer Layers,” which was recently published in RRL Solar.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.