Scientists at Japan’s Kanazawa University are seeking to improve the performance of perovskite solar cells by using two special kinds of titanium oxide, anatase and brookite.

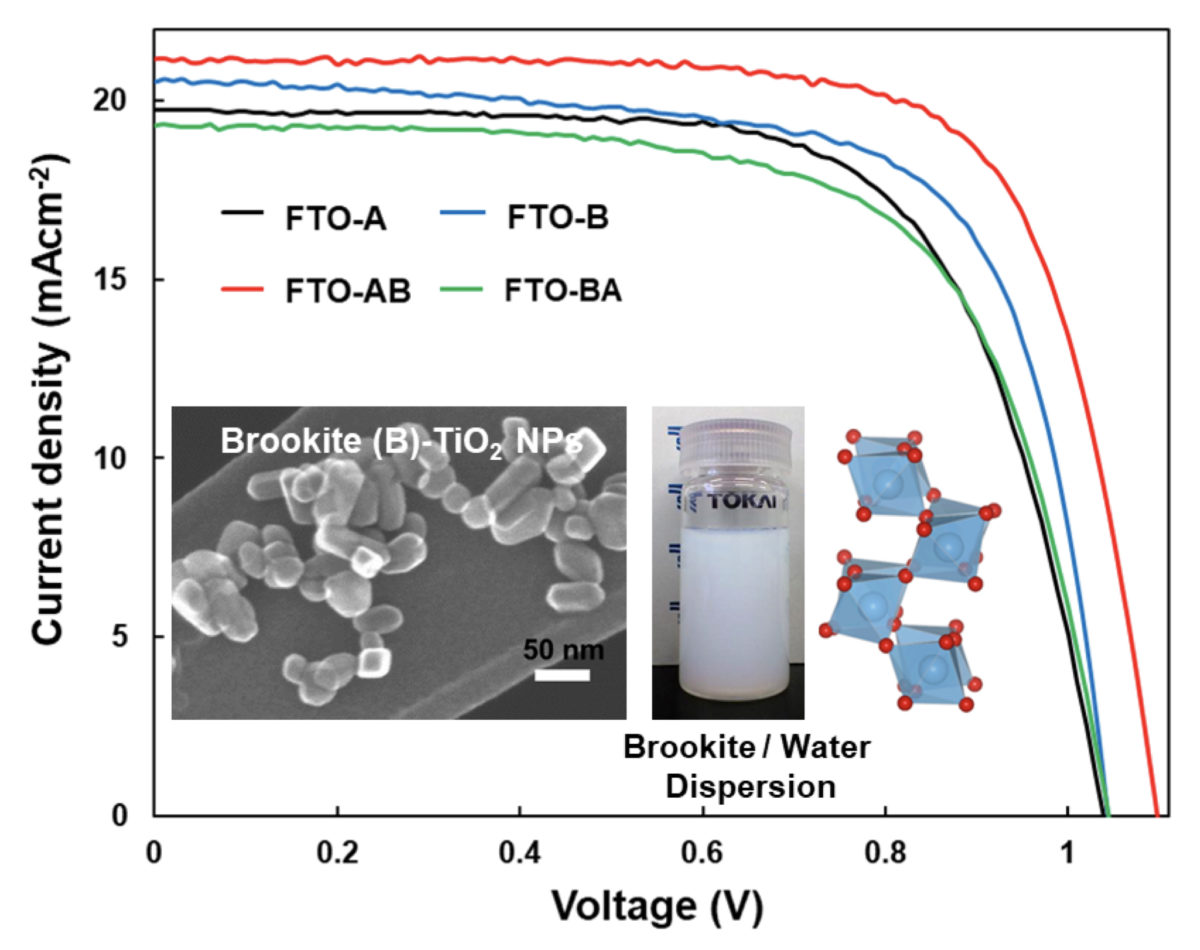

In particular, they claim to have reached a conversion efficiency of 16.82% in a perovskite cell by applying a brookite layer made of water-solute brookite nanoparticles on an anatase layer. This, according to them, enables to improve the transport of electrons from the center of the cell to its electrodes, while also preventing charges from recombining at the border between the perovskite material and the electron transport layer.

“Together, both these effects allow us to achieve higher solar cell efficiencies,” said the research coordinator, Md. Shahiduzzaman.

The research team stressed that the anatase layers were created by spraying solutions onto glass coated with a transparent electrode that was heated to 450 °C, while the brookite layers were produced with water-soluble brookite nanoparticles, as this kind of ink is more environmentally friendly than conventional inks.

The scientists have also made comparisons between different options as using anatase or brookite separately or combination layers with anatase on top of brookite or vice-versa. The also highlighted how previous researchers had discovered that thin layers of titanium oxide are both transparent and able to transport electrons to the electrode.

Popular content

In January of this year, another group of Japanese researchers announced it used tin dioxide (SnO2) instead of the more commonly used titanium dioxide for the production of a perovskite solar cell.

Earlier in March, a group of scientists from the U.S. Department of Energy’s (DOE) Argonne National Laboratory showed the research results into the replacement of titanium dioxide in the manufacture of solar cells.

Scientists around the world have looked into substituting the lead in common perovskite designs with various materials, including titanium, tin and bismuth.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.