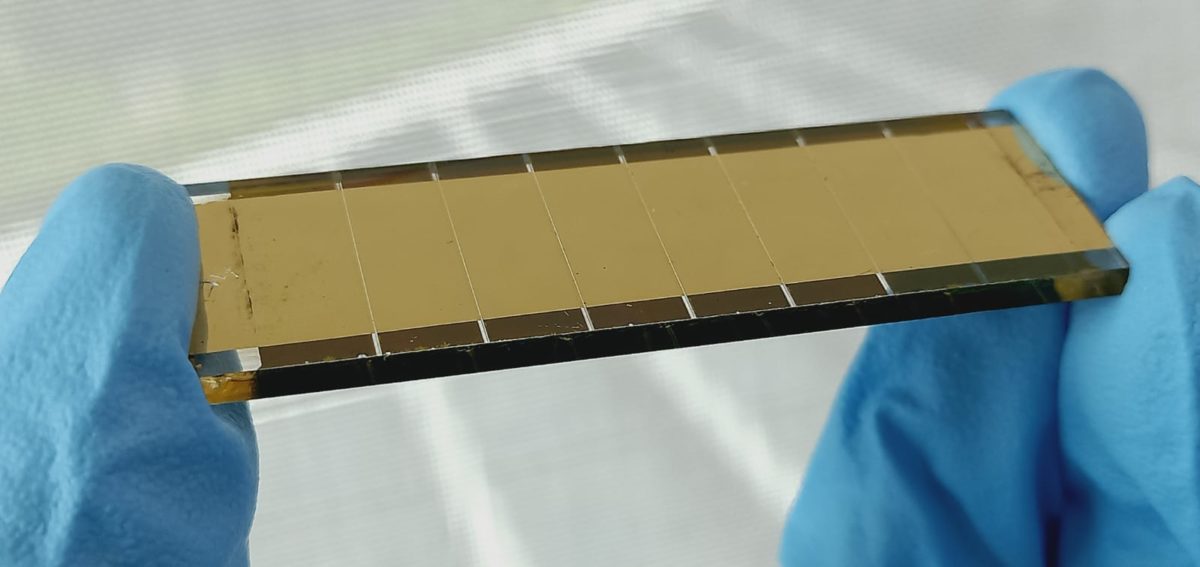

Scientists from Singapore's Energy Research Institute at Nanyang Technological University have developed a mini solar module based on thermally evaporated perovskites with an efficiency of 18.4% and a geometric fill factor (GFF) of around 91%. They believe the panel represents a step forward in the industrialization of perovskite mini-modules.

They described the special panel in “Design of Perovskite Thermally Co-Evaporated Highly Efficient Mini-Modules with High Geometrical Fill Factors,” which was recently published in Solar RRL. It has an active area of 6.4 cm2 and is based on co-evaporated methylammonium lead iodide (MAPbI3).

“MAPbI3 thin films with an optimized thickness of 750 nm,” researcher Annalisa Bruno told pv magazine. “The films were used to build solar cells with an ‘n-i-p' layout on fluorine-doped tin oxide (FTO) glass substrates.”

The researchers noted that a strong drop in the module efficiency – from around 19% to 15% – occurs when the cells are scaled up to 7.5 cm2. This is caused by FTO sheet resistance, which determines the drop in the fill factor. In order to address this issue, the scientists adopted a modular design based on the optimization of the size of the subcells and the dead areas.

“This made it possible to scale up 40 times the active areas of our thermal evaporated perovskite solar cell with a suitable perovskite solar module design power conversion efficiency losses are as low as just 0.7%,” Bruno explained.

They scaled up the size of the cells by maintaining a rectangular shape and a constant width.

Popular content

“Both the careful design of the active areas and the high uniformity of co-evaporated perovskite film can guarantee minimal power efficiency losses during scaling up,” the researchers said.

The high fill factor is ensured by the fact that the number of subcells in the module can be increased, due to the modular design. However, this makes the geometric fill factor decrease, due to the higher number of connections.

“At the same time, minimizing the dead areas by reducing the number of connections and by reducing the width between the sub-cells can substantially increase the GFF,” researcher Subodh Mhaisalkar added. “Our laser-etching scribing process could guarantee a dead area width of 0.06 cm which can achieve a GFF of 91%.”

In previous experiments, the scientists achieved a GFF of 72%. The same group said in April that it had developed opaque and semitransparent perovskite solar panels that could be easily integrated into a range of urban contexts, including building facades, gates, and windows. The 21 cm2 mini panels are also made of perovskite solar cells based on methylammonium lead iodine (MAPbI3)

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

5 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.