The past year has seen plenty of research focused on large-scale processes to bring the impressive achievements made with perovskite thin films into large-scale production. And while there’s still plenty of disagreement over how long we’ll have to wait before seeing the technology take significant market share, perovskites are widely expected to have a major role to play in the future of PV.

And the first commercial iteration of the technology will almost certainly be in the form of a tandem cell, with a more conventional silicon technology sitting underneath. While much of the research community continues to focus on ironing out issues with the perovskite material, Germany’s Fraunhofer Institute for Solar Energy Systems (ISE) decided to look into the silicon cell underneath, evaluating the performance of various cell types for their compatibility with a perovskite top cell, aiming to identify pathways to higher energy yields from solar, at lower costs for manufacturing and deployment.

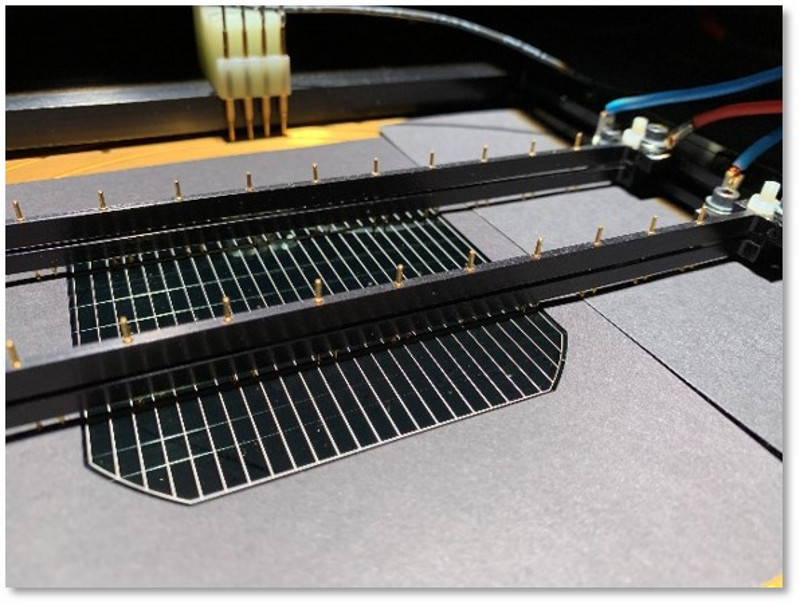

The research, described in the paper The race for the best silicon bottom cell: Efficiency and cost evaluation of perovskite-silicon tandem solar cells, published in Progress in Photovoltaics, takes in four silicon cell types, taking in PERC, TOPCon and heterojunction designs, and two different strategies for coupling the two cells. It also evaluates both planar and textured silicon surfaces, as well as both mono- and bifacial cell designs.

Race for the bottom

Each approach was evaluated using an experimentally validated ray-tracing simulation model, giving a calculated efficiency potential. Then, manufacturing costs were calculated using a model based on existing silicon production, and LCOE calculations based on a fixed-tilt installation in southern Europe.

In every case, the tandem cell was shown to improve LCOE, and differences between the silicon cell types investigated all fell within the model’s uncertainty parameters. “…all tandem concepts have the potential to yield a significantly lower LCOE compared with the conventional PERC concept for both residential and utility installation promising an LCOE reduction of about 11%,” the researchers state. “…to our best knowledge, the ‘race' for the best silicon bottom cell in terms of industrial application is still open to all the investigated bottom cell technologies.”

Popular content

This may sound inconclusive; however, the group goes on to note that the majority of work on tandem cells has so far relied on heterojunction cells for the silicon element, in pursuit of the maximum possible efficiency. That more established technologies including PERC and TOPCon could also be cost-effectively used as tandem cells will surely be of interest to those already running large-scale production with these technologies, and running out of other routes to boost efficiency.

It should also be noted that the cost models assume a 30-year lifetime for the modules, which is not a given for perovskite technology. “…it is important to underline that the presented LCOE potential of perovskite‐silicon tandem modules depends on achieving a comparable lifetime, degradation rates, and financing conditions (i.e., bankability) for the tandem configuration to the reference PERC modules,” the paper notes.

To account for this, the group calculated an LCOE ‘breakeven’ point, noting that assuming a 30-year project lifetime, a tandem module would have to perform for at least 21 years to have a lower LCOE than current generation PERC technology. And, with very few doubts surrounding the efficiency, ensuring this long-term performance and quality should be the direction of new research. “attention should be directed to technological feasibility, upscaling and the production environment, as well as high module lifetimes and field performance,” the Fraunhofer ISE researchers conclude. “It will be most essential for the Pero‐Si tandem technology to overcome these fundamental prerequisites in order to actually achieve lower LCOE with respect to conventional PERC stand‐alone devices and other competing technologies like all‐perovskite tandems.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.