A group of researchers from the Uppsala University in Sweden and Swedish technology company Solibro Research AB has developed a PV-powered electrolyzer for water splitting that is claimed to have remarkable solar-to-hydrogen (STH) efficiency.

Presented in the paper NiMoV and NiO-based catalysts for efficient solar-driven water splitting using thermally integrated photovoltaics in a scalable approach, published in Cell, the device is described by its creators as an electrolysis device combining copper, indium, gallium and selenium (CIGS) thin-film solar modules with an alkaline electrolyzer based on a trimetallic cathodic catalyst made of nickel, molybdenum, and vanadium (NiMoV) and an anode made of nickel oxide (NiO).

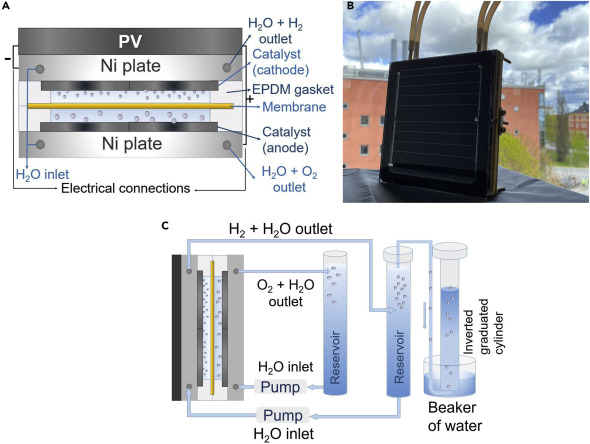

In the proposed system configuration, the anodic NiO electrocatalyst is used as a counter-electrode to the NiMoV cathode. The anode and cathode of the electrolysis cell were placed in close contact with each other and separated by an anion exchange membrane and thin glass was used as the wall of the cell to enable thermal coupling and heat exchange.

“The anodic and cathodic catalysts were positioned in close connection in the design to minimize mass transport limitations in the design, where modules of the size constructed here could be assembled into arrays for larger area installations for convenient maintenance and replacement of separate modules,” the scientists explained. “The approach allows a heat transfer between the PV and electrolysis parts beneficial for improved system efficiency, where a decrease in PV efficiency from high operating temperature is compensated by increased electrolysis efficiency, and vice versa for low operating temperature.”

Popular content

A 14.5%-efficient CIGS module with an area of 78cm2 was placed in thermal contact with the electrolysis device that has an active area of 100cm2. The operating voltage for the combined PV-electrolyzer system was estimated at 1.63V. Nickel plates measuring 130×130×5mm were used to cover the electrolyzer in order to minimize corrosion and ensure long-term stability.

The performance of the solar-powered electrolyzer was evaluated with operating temperatures ranging from 25 to 50 degrees Celsius and under standard solar illumination. The champion device, built with a 4-cell solar module, was able to provide an average solar-to-hydrogen (STH) efficiency of 8.5% for stable operations during 100 hours. Its maximum efficiency reached up to 9.1%. “The results in the present study bear promise toward large-scale implementations using matched integrated PV-electrolysis with stable thin-film PV materials, monolithic design, and utilization of earth-abundant catalyst components,” the researchers stated.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Was soll daran vielversprechend sein? Die Kombination aus einer stinknormalen Solaranlage und einem alkalischen Elektrolyseur hat eine Effizienz von fast 15 % und das ohne Molybdän und Vanadium im Katalysator.