Researchers at Germany's Fraunhofer Institute for Solar Energy Systems ISE have developed a bottom-up cost model for alkaline (AEL) and proton exchange membrane (PEM) water electrolyzers on behalf of the Clean Air Task Force (CATF), a U.S.-based non-profit advocacy group and thinktank on climate and energy.

“The cost models are based on a bottom-up approach of the institute, in which typical layouts of the electrolysis plants are first designed and then technical parameters are determined by a steady-state simulation of the energy and mass balances in the systems,” the Fraunhofer ISE stated. “Based on these specifications, the cost shares of the individual subsystems and components are determined via price quotation from manufacturers and suppliers and via specific cost functions.”

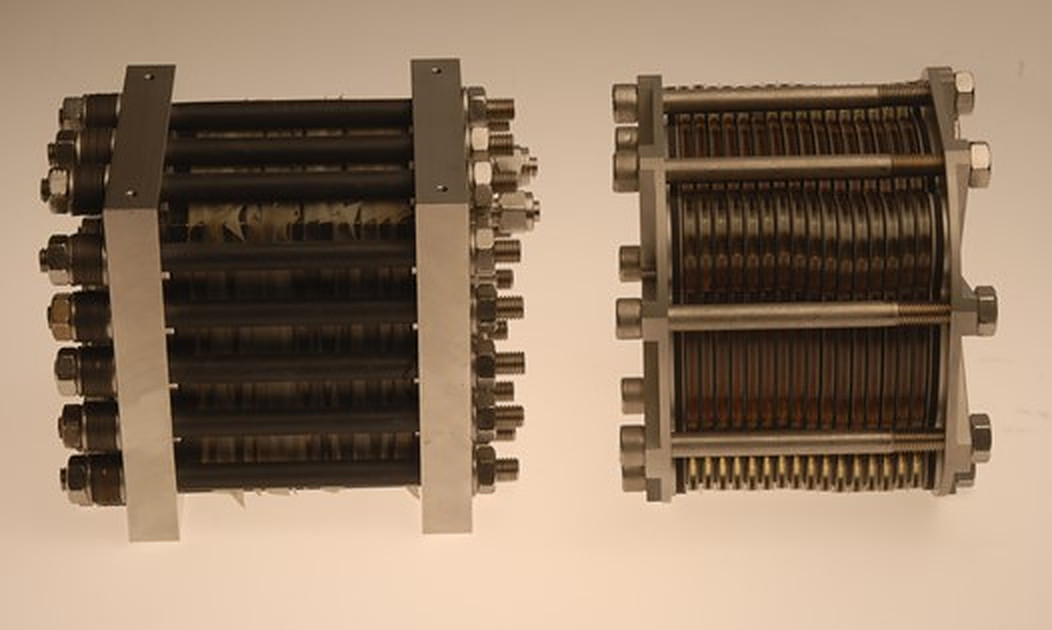

In the study “Cost Forecast for Low-Temperature Electrolysis,” the scientists provided a comprehensive analysis of the cost structures

of alkaline and proton exchange membrane electrolyzers taking into account technology costs reported for 2020 and those projected for 2030.

Their analysis considered two electrolyzer systems, with capacities of 5MW and 100MW, for the alkaline and PEM technologies. “The PEM cell, stack and system components are designed for an operating pressure of 30bar,” the paper reads. “The AEL cell and stack design is oriented on well–proven and advanced chloralkali electrolysis designs including operation at atmospheric pressure, which makes additional mechanical compressors on the system side necessary to ensure a comparability between both technologies.”

For the AEL technology, the number of stacks was assumed to be two in 2020 and one in 2030, for the 5MW, project and 40 in 2020 and 20 in 2030 for the 100MW system. For the PEM electrolyzer, the number of stacks for the 5MW system was indicated at five in 2020 and one in 2030, while for the 100MW installation, their number was 100 in 2020 and 20 in 2030. “Due to technological progress and a scale-up in the active area, the specific stack costs can be practically halved within 10 years for both types of electrolysis stacks, from about €200/kWdc to below €90/kWdc for AEL stacks and from €380/kWdc to about €220/kWdc for PEM stacks,” the research group emphasized.

Popular content

The rated current density for both AEL systems is expected to increase from 0.6A/m2 in 2020 to 1A/m2 in 2030. For both PEM electrolyzers, this value is estimated to increase from two to 3A/m2.

Through their analysis, the researchers found that the alkaline electrolysis costs are lower, compared to those of the PEM technology, due to the lower costs for the stacks. “However, depending on the system size, this cost benefit for the AEL systems is almost negated by the need for an additional mechanical compressor,” they further explained. “The compression unit contributes a large part to the AEL system cost as well, but offers strong cost reduction potential by sizing-up to larger capacities, halving the share on the overall costs from 5MW to 100MW system size.”

The cost for the 100MW alkaline electrolyzer is estimated to drop from €663/kW in 2020 to €444 in 2030, and that for the 5MW system to drop from €949 to €726. For the PEM technology, the cost for the 100MW facility should decline from €720 to €500, and that for the 5MW system from €980 to €730.

According to Fraunhofer ISE researcher Marius Holst, the costs of both technologies almost equalize when the effort for downstream compression is also taken into account. “In total, system costs of approximately €400 to €500/kW can be expected in 2030, but decentralized, smaller systems will remain significantly more expensive,” he concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.