Germany's Fraunhofer ISE announced it published a new international test standard for inverters that incorporate arc fault detection devices.

The research institute said the new IEC 63027 standard will replace the UL 1699B standard issued by Illinois-based certification body Underwriters Laboratories (UL) in 2011, when arc fault detectors became mandatory in the United States.

“The new IEC standard eliminates some of the weaknesses of the old US standard, which did not simulate real operation sufficiently,” the institute said. “As a result, many arcs went undetected, because they did not reach the alarm threshold values or because false alarms were triggered.”

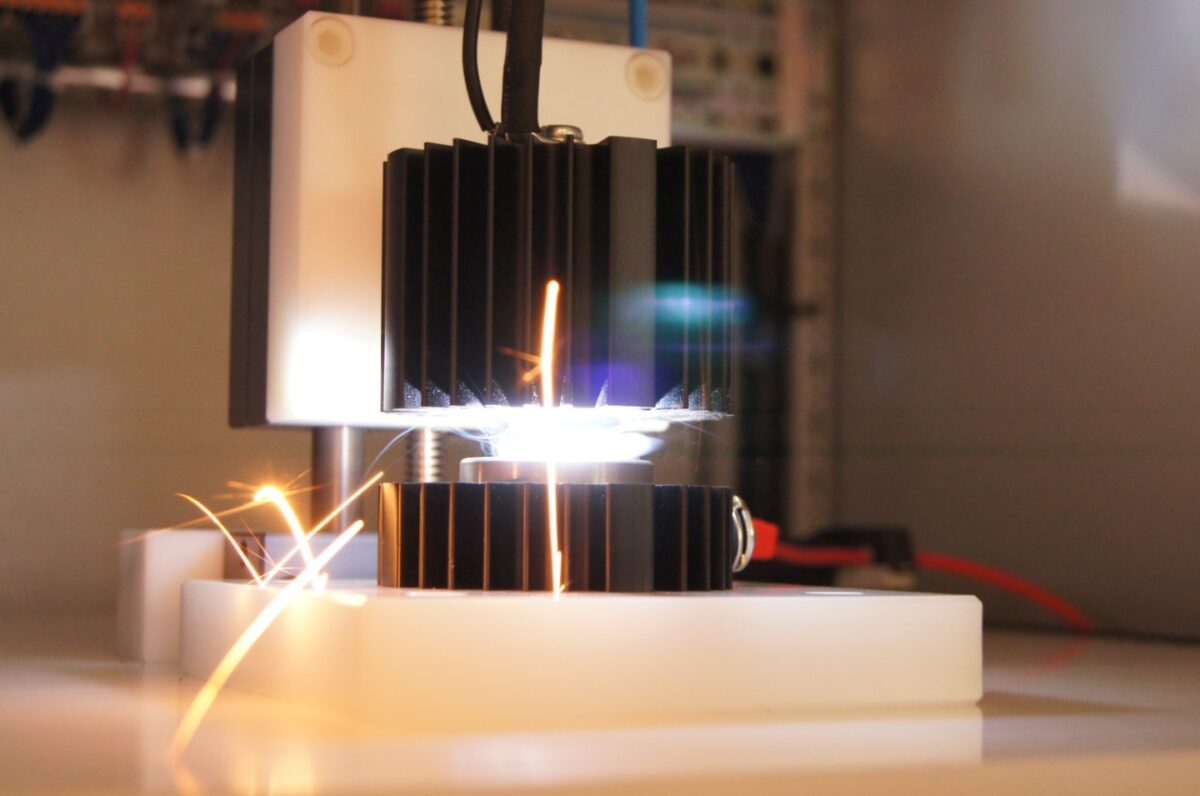

According to the Fraunhofer ISE, undetected arcs and false tripping in solar inverters can be avoided only with a realistic test setup that uses an electronic DC source as a PV simulator instead of real PV modules. ” Current flows from the PV simulator into the inverter through a connection point that can be precisely disconnected,” Fraunhofer ISE experts explained.

“The connection point is a ball-and-socket joint made up of two tungsten electrodes, which are pulled apart at a defined speed, thus igniting a characteristic arc.”

Popular content

The test setup also considers electrode distance and speed, while using a filter network between the inverter and the simulated PV system.

“The time until the inverter is switched off is decisive for the proper functioning of the arc detector: The less time an arc burns, the lower the energy input is into the faulty contact point, i.e., short switch-off times reliably prevent a fire from starting,” the scientists added, noting that arc fault detector successfully passes the test with energy values between 200 and 750 joules, switching off within 2.5 seconds. “Automatic reconnection after detector tripping is allowed four times within 24 hours. After the fifth time it must be reconnected manually.”

The institute said the new test bench is currently deployed at its TestLab Power Electronics, where it is already testing devices for DC voltages up to 1,500 V.

“We are expanding the range of services offered by our TestLab Power Electronics, where we perform accredited tests in accordance with grid codes, efficiency measurements and impedance spectroscopy investigations of inverters,” said Steffen Eyhorn, head of TestLab Power Electronics.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.