Scientists at German research center the Helmholtz-Zentrum Berlin (HZB) are planning to bring perovskite-silicon tandem solar technology to mass production. “Our goal is to increase the efficiency of these novel cells to more than 30% – not only at laboratory scale but also when produced on a commercial scale,” said Bernd Stannowski, head of the Competence Center Photovoltaics Berlin at the HZB.

Stannowski and his group are working on the development of modular manufacturing to enable the large scale production of solar cells on six-inch wafers.

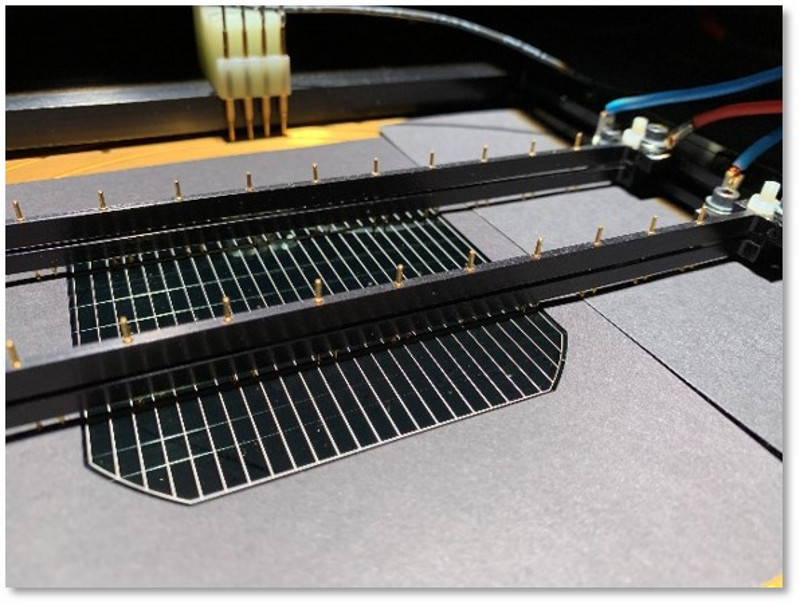

The researchers said, the silicon heterojunction lower part of the tandem cell requires very thin amorphous-silicon contact layers produced using plasma-enhanced chemical vapour deposition (PECVD). The tandem cell developers said they are testing a solution offered by Swiss company Indeotec, which specializes in the development and construction of PECVD/PVD (physical vapor deposition) systems for pilot production and R&D purposes. “As the first system of its kind in the world, it has what is known as PECVD-Mirror process modules, with which silicon wafers can be coated on both sides without having to flip them,” said Stannowski.

For the tandem cell upper layer, the active perovskite material, the HZB’s Integration & Novel Technologies laboratory is designing a vacuum deposition system for various materials, to conduct research into hybrid silicon-perovskite structures with the support of German companies Von Ardenne and Creaphys.

Popular content

Stannowksi said a newly-ordered facility, of which no further details were provided, is expected to integrate all the process steps for fabricating the perovskite top cell. He added: “Using this unique technology, the complete cell – consisting of several layers including the electrical contacts – will be able to be produced automatically and at high throughput.”

HZB scientists achieved an efficiency of 24.16% with a CIGS-perovskite tandem cell in April. That record meant tandem technology efficiency surpassed the 23.35% record for a standalone 1cm² CIGS cell set in January last year by Japanese manufacturer Solar Frontier. HZB also holds the efficiency record for a perovskite-on-silicon tandem cell, at 29.15%.

According to recent research from France, PV modules made with tandem solar cells will have to show efficiencies of 30% and offer the same lifetime and degradation rate as standard crystalline panels if manufacturers want to hit commercial production. That paper – which assessed the potential competitiveness of tandem modules against crystalline silicon products – stated commercial versions of the latter will reach efficiencies of 22-24% this decade, and possibly 25% if interdigitated back-contact heterojunction products reach commercial production.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.