An international group of researchers has fabricated a transparent thin-film solar cell based on antimony trisulfide (Sb2S3) with a power conversion efficiency of 5.5%. The device is intended for applications in solar windows and, according to its creators, may easily reach commercial production as the low–temperature, two–step manufacturing process they developed is compatible with existing window glass manufacturing technology.

The process consists of manufacturing semi-transparent and oxide-free thin films of crystalline Sb2S3 through ultrasonic chemical spray pyrolysis (USP), which is an alternative to chemical vapor deposition (CVD) for the preparation of micro or nano-thin films. “Considering the potential benefits of the capability of ultrasonic spray pyrolysis for large scale production, extensive cost savings could be achieved by depositing all component layers in the Sb2S3-solar cell by ultrasonic spray pyrolysis, further accentuating facile integration in solar window glass production,” the research corresponding author, Malle Krunks, told pv magazine.

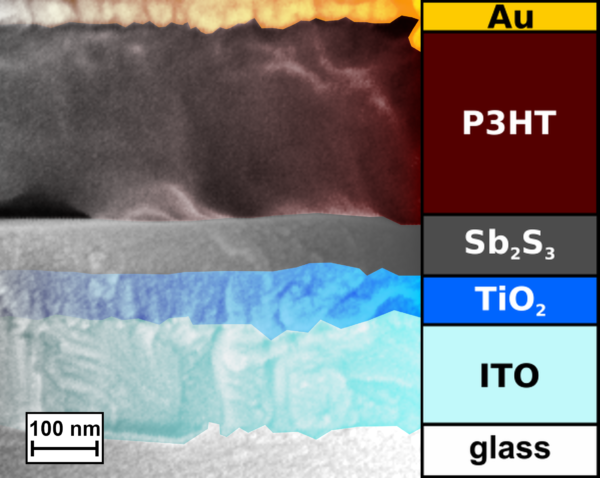

The device was built on a substrate made of glass, an indium tin oxide (ITO) layer, titanium dioxide (TiO₂), with the Sb2S3 layer, poly(3-hexylthiophene) (P3HT) as a hole transport layer (HTL), and a gold (Au) metal contact. Sb2S3 films with thicknesses of 30, 70, 100, and 150nm were tested to find the optimal size and the cells made with 70nm films achieved the best fill factor, of around 57%, while the highest power conversion efficiencies were achieved with films ranging from 70 to 100nm.

Image: Tallinn University of Technology

A cell with a 1.7mm2 area achieved an efficiency of 5.5% and another device with a 7.1mm2 cell area reached 4.7%. Both values are described by the scientists as top performances in the last five years, and close to the record efficiencies of planar solar cells based on pristine Sb2S3.

This remarkable result was achieved, they went on to say, thanks to the optical spacer effect, which usually occurs in solar cells with a very thin HTL and absorber. “The optical spacer effect can have a strong influence on the efficiency when the thickness of the absorber is around 100nm or less,” the academics specified. “Holes photogenerated near the electron‐transporting material/Sb2S3 interface, which must travel the farthest towards the HTL, face mobility issues when traversing the thickest (150nm) absorber layer.”

Popular content

The cell also showed average visible transparency of 26%.

“It is a bit difficult to compare the cost due to the fact that one needs to account for the scaling up of the fabrication process and that is a bit cumbersome to forecast precisely but, based on the current cost of material and processes involved, and assuming an efficiency of 5%, I expect a price that is between $550 and $650/kW,” researcher Matteo Chiese stated when asked about the cell costs. “This is quite comparable with the rooftop PV module cost in Germany for the fourth quarter of 2019 – $500/kW. If we manage to reach an efficiency of 6% we are going below the 2019 module cost per kilowatt published by Germany's Fraunhofer Institute for Solar Energy Systems ISE.”

The solar cell architecture was unveiled in the paper Semitransparent Sb2S3 thin film solar cells by ultrasonic spray pyrolysis for use in solar windows, published in The Beilstein Journal of Nanotechnology. The research team includes scientists from the Tallinn University of Technology, in Estonia; the University of Nevada, in the United States; and Germany's Karlsruhe Institute of Technology (KIT).

*The article was updated on December 15 to reflect that the research corresponding author is Malle Krunks.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.