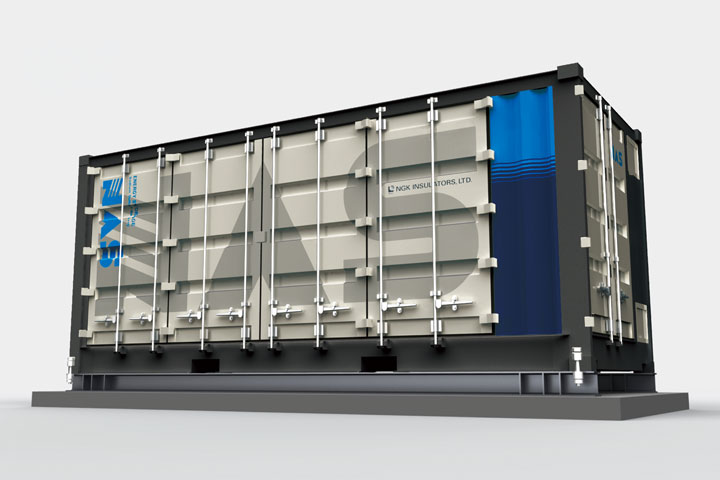

Japan's NGK Insulators has started operating four 250 kW/1.450 MWh sodium sulfur battery containers at a KEPCO testing site in Naju, South Korea.

The ceramics manufacturer and storage provider says its flagship NAS battery systems will be used under a demonstration project for the comparison of performance of stationary storage batteries, the results of which will set performance standards for large-scale energy storage batteries in South Korea.

NAS batteries consist of sodium as the negative electrode and sulfur as the positive one. A beta-alumina ceramic tube functions as electrolyte, which allows only sodium ions to pass through.

When discharging, sodium is oxidized, and sulfur is reduced to form polysufide. The charging step recovers again metallic sodium and elemental sulfur.

NAS batteries are rated at 4,500 full cycle discharges or a 15-year calendar life. The battery runs at temperatures of around 300 C. Both elements are in liquid state when the battery is operational.

The batteries are suited to long-duration applications and capable of discharge at full output for six hours, or at one-third of full output for up to about 18 hours.

Popular content

NGK says that NAS batteries make 24/7 power supply feasible with solar power for 6-10 hours and a NAS battery for 14 to 18 hours at one-third of the rated output.

NAS batteries have obtained the certification based on stationary storage battery safety standard UL 1973 (cell and module level) and a test report based on UL 9540A standard.

The KEPCO project is not the first one for NGK in South Korea. In 2020, a NAS battery was delivered to electric power systems manufacturer G-Philos for the first power-to-gas (P2G) demonstration project in the country, carried out by Korea Midland Power Co., Ltd. (KOMIPO) at Sangmyung Wind Farm, Jeju Island.

According to NGK, NAS batteries have been installed at over 250 locations worldwide, with a total output of more than 720 MW and total capacity of approximately 5 GWh installed. They are used for various applications, including peak cutting through load balancing and emergency power supply, as well as stabilization of renewable energy and construction of smart grids.

Last year, NGK Insulators entered the perovskite PV module business with the acquisition of an unspecified stake in EneCoat Technologies, a Kyoto University PV technology spinoff. Enecoat develops perovskite solar cells through a wet process based on organic chemistry, a low-temperature coating process, and roll-to-roll printing.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.