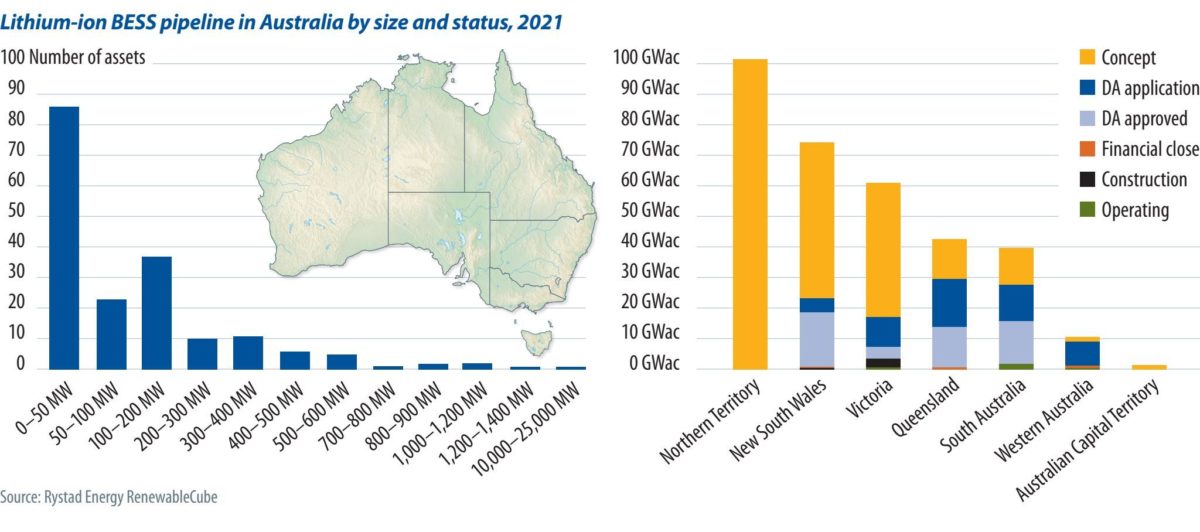

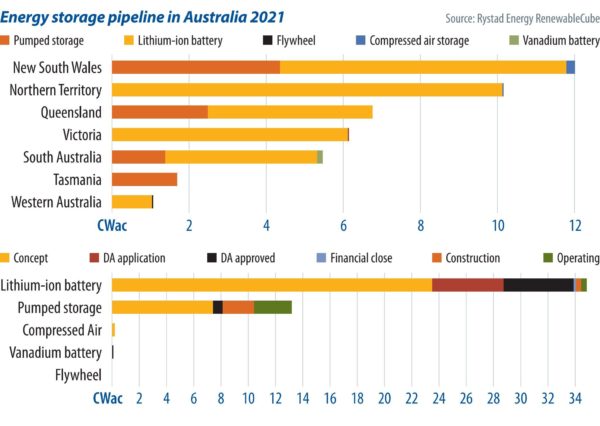

It was no secret, but the Covid-19 pandemic has emphasised just how risky Australia’s extremely low appetite for risk really is. Zero Covid-19 policies might have some theoretical basis, for a time, but like everything else in life, failure is inevitable. The Victorian Big Battery (VBB) blaze is another example. Australia’s growing number of battery energy storage systems (BESS) were supposed to smooth the energy transition, but one concatenation event and the public reaction was clearly one of unpreparedness.

When it comes to the safety issues with BESS, there are few individuals more informed than Newcastle University’s (U.K.) Paul Christensen. He notes that we are still on the frontier of knowledge about BESS (particularly lithium-ion) and suggests that our current transition is analogous to the transition to internal combustion engines in the early 20th century.

When it comes to BESS, the problem isn’t new. In fact, it has been a law of nature since the Big Bang – great concentrations of energy want to detonate, and lithium-ion batteries are incredible concentrations of stored energy. The key, says Christensen, is to mitigate the relatively low risk as much as possible, which means planning for failure and involving emergency services in the site design of BESS.

Slow burn

After burning for three days, the fire at the VBB in Moorabool, Victoria, was declared under control at 3:05 p.m. on Aug. 2. At this point, according to a statement supplied to pv magazine by the Country Fire Authority (CFA), “firefighters successfully completed the operation of opening all doors to the container of the battery, with no sign of fire.” The CFA confirmed the fire was “non-suspicious, and investigators have deemed the cause of the fire to be an electrical fault.” However, the nature of said “electrical fault” is still to be determined by a “multi-agency fire investigation,” not to mention Neoen and Tesla’s own investigations.

Marnie Williams, commissioner and chairperson of one of those investigating agencies, Energy Safe Victoria (ESV), said that it “is providing all resources required to ensure a complete and thorough investigation, which will take as long as necessary. If there are learnings to come from this incident, we will make them public.”

Though no conclusions have yet been determined, paying attention to what can be learned is the right idea, as BESS is currently on the kind of radical learning curve that seems staggering and can induce anxiety at the time, but tends to lead to exponential growth through Moore’s law.

Stedman Ellis, CEO of the Future Battery Industries Cooperative Research Centre agrees, noting that “learning from such events as the Victorian Big Battery incident is critical to progress toward building a sustainable energy system given the pace of implementation of large-scale energy storage systems in Australia.”

Smoke without fire

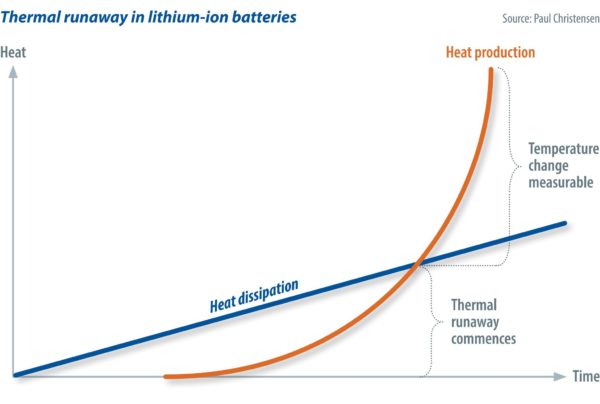

Of course, the VBB incident is not the first of its kind, and certainly not the most dramatic. In one notable case in April 2019 at the McMicken Energy Storage Facility in Surprise, Arizona, an explosion seriously injured four firefighters. A DNV technical investigation found one LG Chem 0.24 kWh nickel manganese cobalt (NMC) pouch cell had experienced an “extensive cascading thermal runaway event.” Its report concluded that while the site’s fire suppression system worked as designed, it was insufficient to prevent or halt the runaway concatenation of events.

However, in a recent “overheating” event at the Phase I (300 MW) Moss Landing Energy Storage System in California, it seems the fire suppression system worked effectively. “There are multiple layers of safety integrated into the battery facility,” said Vistra Energy, the project’s owner and operator. “And the risk mitigation and safety systems worked as designed, detecting these modules were operating at a temperature above operational standards and triggering targeted sprinkler systems. As a result, the overheating was controlled and contained without the need for outside assistance.”

According to Christensen, there are two consequences to thermal runaway events. The gases can ignite immediately and “you get, typically, flare like flames, you’ve seen them on Teslas coming from underneath.” This is what happened at the VBB. Or alternatively, the gases don’t ignite immediately and “you’ve got the potential for what is called a vapor cloud explosion –that’s a violent explosion. That’s what happened in 2019 at Surprise.” So, in much the same way as it is the smoke which is often more dangerous than fire in an enclosed space, it is the gases which can pose the most danger in a battery fire.

“At no point in that incident was there a fire inside the container,” Christensen said of the Surprise vapor cloud explosion. “There was no fire. The cells were sequentially going into thermal runaway and generating a dense white vapor cloud. When they [the firefighters] opened the door three hours after the initial smoke alarm triggered, that vapor cloud exploded.” In hindsight, then, the fact that the VBB ignited immediately was actually good news, because “your average firefighter knows how to deal with fire and toxic gas … If it doesn’t ignite immediately, that’s when it poses a problem.”

Firing line

A spokesperson from Fire and Rescue NSW (FRNSW) told pv magazine that lithium-ion battery fires “can pose unique challenges … firefighters gather as much information as possible before deciding whether or not to enter any building or compartment with burning lithium-ion batteries as there is a potential for a vapor explosion.”

Moreover, part of the problem with battery fires, aside from the toxic gas and self-sustaining thermal runaway, is that typically the seat of the fire is a difficult place to douse with water. Indeed, in an EV the battery pack is often encased in steel, and in a BESS the doors the firefighters need to get water through are the very doors that may, in Christensen’s words, “go bang.” For firefighters this leaves only to douse the battery container itself and cool the containers nearby to stop the spread.

“Firefighters are trained not to open the battery casing for water application to the cells due to the hazards of high voltage stranded energy and risk of electrocution,” continued the FRNSW spokesperson. “The preferred option as advocated by manufacturers is to allow the battery to completely burn out, removing all hazards.” Smaller batteries may be submerged in a water bath “to aid extinguishment,” but that leaves the problem of disposing the polluted water.

Not too big to fail

“Lithium-ion batteries are essentially stable, unless they’re abused,” said Christensen. Abuse can range from overcharging to poor ventilation, from condensation to “a freak concatenation of events.” As for condensation, we can probably rule that out in the case of the VBB, as Moorabool isn’t the dampest of places, but in places like England, Christensen noted, condensation can cause isolation breakdown leading to cell failure.

As the ongoing investigation into the Victoria Big Battery blaze demonstrates, determining the nature of a failure is not always easy. But as for the recent spate of recalls of EVs and domestic storage systems, Christensen says. “We often suspect that it is either a defect or a contamination introduced in the manufacturing stage.”

Despite this, Christensen is certain that “lithium-ion batteries are a great thing, and I strongly believe we will manage the risks, but we’re on a massively steep learning curve at the current time and I think the penetration of lithium-ion batteries into our society has outstripped our knowledge of the risks and hazards.”

“The important thing,” Christensen continued, “is to monitor voltage at the cell level, the granularity. If you only monitor at the module or rack level … when a cell fails you might miss it.” Of course, there are other levels of safety, too, including early detection systems, thermal barriers, extinguishing and cooling systems, and deflagration vents – a precaution that would infuriate the great English actor Michael Caine, because they ensure “that explosions are directed upwards instead of blowing the [bloody] doors off.”

Before sensors and vents are relied on, precautionary action can be taken right at the outset. Christensen advocates this at the design phase. “You need to be sitting down while you’re designing this and saying ‘What if?’ ‘What if?’ ‘What if? Not only do you design the system for safety, but you also design the system so that it can tolerate failure. You should be designing systems to ensure that the fire services can deal with any emergency.”

Such design features could include an uncluttered site for emergency service personnel, and ensuring easy access to fire hydrants. “Lots of them,” Christensen added. “Because you need lots of water; you’re not only trying to cool the container, but douse the gases as well.”

The FRNSW spokesperson concurs with such an approach, adding that there has been “an increase in the number of proposals being referred in recent times, however, it should be noted that not all buildings/sites containing BESS are being referred. It is important that FRNSW are consulted during the design process.” And what firefighters consider in the design process is “compartmentation and separation, site access, water access, water containment, detection and suppression systems, ventilation, site communication and battery information.”

There is no way to eradicate the instances of failure, concluded Christensen: “It’s the inevitability of probability.” This means that the best course of action is to learn as much as possible about the risks and design our systems to tolerate and contain the inevitable failures.

Worthy alternatives

There are other avenues for improving the safety of BESS. Material scientists are working on novel solutions that are more stable, or at least, less-flammable. Australian researchers Mega Kar and Binayak Roy, from Deakin University, are part of a team doing just that. The researchers helped to develop a novel salt solution that proved much more stable at room temperature, the atmospheric conditions in which traditional electrolytes undergo hydrolysis, generating toxic hydrogen fluoride and causing electrolyte degradation.

“Our novel salts show superior atmospheric stability over many cycles, such that unwanted hydrolysis and formation of side products are eliminated,” said Kar. “The niche thing about these novel fluoroborate anions is that they can be easily turned into non-volatile, non-flammable liquid salts, which can significantly reduce the chances of thermal runaway.”

While not the only cause of failure, the moisture sensitivity and flammable nature of conventional electrolytes is one reason a battery can catch fire. “By replacing the conventional salt with our borate ester salt, we have been able to break that chain of events,” said Kar, who didn’t neglect to mention that thermal runaway can be triggered by other catalysts, such as “the uncontrolled charging of cobalt.” To combat this problem, Monash University, in partnership with Deakin University and Calix Ltd., developed cobalt-free manganese-based batteries.

There is also Sydney-based Gelion Technologies’ redesigned zinc-bromide solar batteries. Founded by University of Sydney chemistry Professor Thomas Maschmeyer, Gelion’s innovative electrolyte gel is being touted, by Maschmeyer himself, as a competitor to lithium-ion, with advantages on the safety front, as the gel is a fire retardant. What is more, unlike lithium, which contains a stored charge even when “fully discharged,” the Gelion battery can be completely discharged to zero volts without loss of function, making them “very abuse tolerant.”

For firefighters arriving at a battery fire, a fully discharged state would be welcome news, as would their involvement in the early stages of BESS project development.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.