Of the PV capacity installed before 2013, 25% was or continues to be affected by PID. For plants commissioned after 2013, the figure to date is only 0.9%. This is the result of a survey conducted by pv magazine of major plant management companies in Germany. This astonishingly positive development raises questions, of course. Do modules certified as PID-free keep their promise? Or is the process merely progressing more slowly today, only to rear its head at a later date?

Can we believe the data?

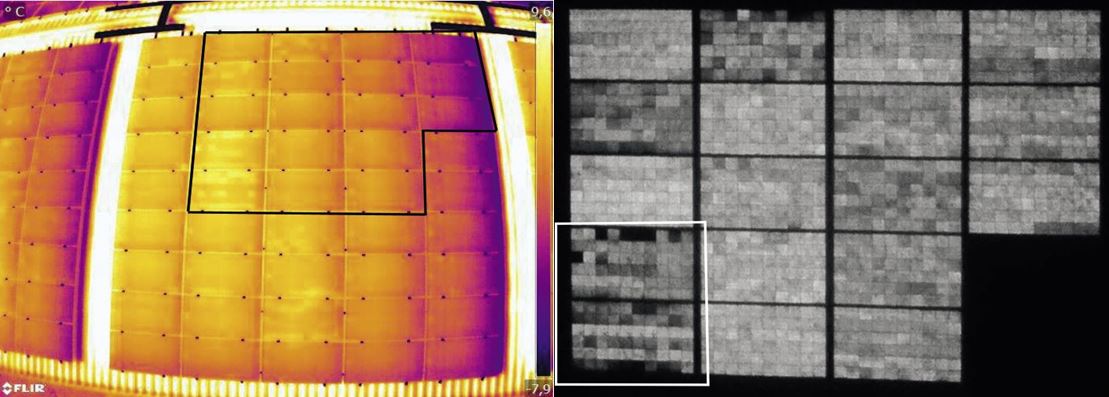

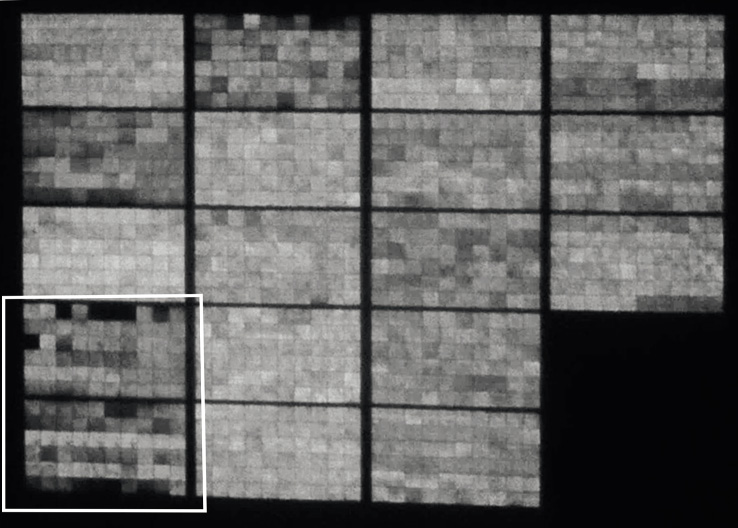

Yes, because although some operators chose not to participate, the data also seem to be consistent with the previous pv magazine survey on the subject. In 2016, 19% of surveyed systems were affected by PID and also went into operation before 2013. Since then, PID has been discovered in many older systems. The information was provided by operators who monitor their plants very closely. There are uncertainties, however. The safest way to identify PID is to use thermal or EL imaging. But large ground-mounted and roof-mounted systems are rarely examined systematically with imaging methods. At best, random checks are made during inspections if the weather is right. Only a few operators scan plants completely as standard practice.

Can PID be considered a thing of the past?

No. Although the phenomenon is no longer as prevalent in Germany, it is still a major concern internationally. Steven Xuereb, Director of PI-Berlin, often observes PID in newer plants in warm and humid climates, such as India, Israel, the Mediterranean, and in Great Britain. This is not reflected in the German statistics and indicates that the modules still have flaws. In view of the fact that fewer systems have been installed in Germany since 2013 and that the German climate is usually cooler and drier, one can assume that PID cases, if they still exist, do not show up until much later and we were therefore unable to find any more recent cases. Dieter Schenker of Padcon says that the challenge is to detect PID as such, since it can initially be obscured by normal degradation due to age and is accepted by many plant owners as an anticipated drop in performance. “If a plant degrades noticeably by 0.9% per year, some customers accept this as a slightly above-average degradation due to age. However, if part of the cause is PID, they will accept losses that they could simply avoid with a PID box.”

Are new modules immune or not?

About six years ago, manufacturers gradually began to have modules tested for PID. In one version of the test, negative voltage is applied to PV panels for 96 hours in high humidity (in the range of 85%) and temperature (60 degrees Celsius). The module passes if its output is degraded by less than 5%.

After the introduction of PID testing, the question has repeatedly been asked whether these tests are suitable for avoiding PID. There are several reasons behind the question: First, although modules often remain below the degradation limit, they generally still exhibit a low degree of degradation. Some experts therefore also speak of the fact that every module is PID-prone, even if it passes the test – the only question is: To what extent? Second, although manufacturers have modules tested, it is often not clear to buyers whether the purchased modules contain the same materials. And materials are crucial for PID resistance.

According to the survey, these doubts were unfounded. The result is clear that there was virtually no PID in plants built after 2013. Even an appeal in the pv magazine newsletter did not result in any relevant PID-affected performance in systems after the reporting year.

In the pv magazine module test program launched last year, modules taken randomly from production are also tested for PID resistance. So far all of the modules have passed (more at: www.pv-magazine.com/pv-magazine-test/).

Nevertheless, it is still too early to give the all-clear, because another effect not yet widely known by experts could cause problems in the future: namely, modules subjected to weathering are more susceptible to PID. The test does not consider this, since it is performed on new modules and the applied stress does not properly reflect these weather influences.

Why are aged modules more susceptible to PID?

Scientists such as Volker Naumann from the Fraunhofer Center for Silicon Photovoltaics CSP have investigated the mechanisms of potential-induced degradation. They emphasize that the conductivity of the EVA film plays a decisive role. The lower the conductivity, the less leakage currents occur between the solar cell and module surface/frame. However, the conductivity of the EVA film increases when it retains moisture. This happens over time in the field, but not during the shorter test in the laboratory. The test does not reflect the real aging behavior of the modules. In other words, susceptibility to PID may increase with the age of the modules, especially when high humidity, high temperatures, and high irradiation are combined.

It is thus possible that modules that are initially largely PID-resistant will develop it later. However, the onset of the degradation process will likely be delayed and not progress so rapidly.

Are there modules that show PID resistance even in old age?

Yes, such modules exist. To understand how this works, we need to look at the cause of the effect in the cell: “This occurs when sodium ions migrate into tiny crystal defects on the surface of the cell through leakage currents,” explains Naumann.

This increases the width and depth of the defects. When they reach the p/n junction, which is the crucial interface in solar cells between the two differently doped silicon layers, “a short circuit occurs.” Many short circuits over time lead to a failure of the entire area. According to Naumann, a more conductive anti-reflective layer could prevent this effect by removing the sodium ions from the surface. This does not mean that they have to be conductive in the sense of an electrical conductor, “only more conductive than the Si2N3 used up to now,” says the scientist. “This can be achieved by increasing the proportion of silicon, for instance.” The combination of a conductive anti-reflective layer and insulating EVA film is the ideal way to create resistant modules, but it is more expensive than just modifying the EVA film or the anti-reflective layer. With this in mind, it is possible that opting for more expensive modules may help, although there is no guarantee of this.

Why is it not standard to build PV systems that prevent PID?

In addition to using resistant modules, there are other ways to protect against PID. For example, anti-PID or offset boxes that apply a high positive voltage to the negative pole of the modules during the night can reverse PID effects. But this incurs additional costs, which only a few customers are prepared to pay for the sake of prevention.

Dieter Schenker of Padcon says that the sales figures for the Float Controller developed by his company, which applies the positive voltage at night, have steadily increased since its market launch at Intersolar 2013 and have already been installed globally on over 1GW of PV plants globally. Nevertheless, only a very small number of his customers install the controller as a precautionary measure, in his experience.

“The systems we are now retrofitting were built between 2010 and 2014. System operators usually need several years before they can detect power losses and the associated drop in yield,” says Schenker.

The second possibility is to ground the DC circuit at the negative pole if the system at the inverter or medium voltage transformer is galvanically isolated from the grid. But this has another disadvantage. It prevents insulation faults from being reliably reported to the monitoring system, says Robert Golz of Enovos.

This is a safety risk and also a possible source of gradual yield losses. The solution Enovos has devised for large systems is to switch off the grounding temporarily by remote control to collect error messages and allow installers to work safely.

What are manufacturers doing?

Manufacturers continue working to minimize PID susceptibility, as modules need to become even more resistant for emerging markets in the tropical and subtropical latitudes.

The further refinement of EVA films and the use of POE films, frameless modules, or glass-glass modules can reduce PID susceptibility. While frameless modules offer fewer opportunities for leakage currents, glass-glass modules are characterized by the fact that the glass cover prevents even older laminates from absorbing significant additional moisture in the EVA film. Particularly when using modules under high voltages, as with 1.500 volt systems, module manufacturers now occasionally require grounding

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.