The cost-competitiveness of solar energy is well known, and it has already reached the grid parity stage in china. The biggest threats to the deployment of large-scale photovoltaics are the rising polysilicon and logistic cost, land procurement due to the national and regional/municipal constraints, diluting the margin of the project due to the increasing cost of land, BOS, and O&M.

This study is aimed at giving in the first part insight into the future trends of photovoltaic technology. This comparison study has been performed on a site in the northwest part of China. The scope was to assess which was the best design solution that maximized the IRR. Therefore, a techno-economic optimization has been carried out on three different systems: the n-type Tiger Neo 72-cell based on 182’ wafer, PERC 55-cell, and 60-cell based on 210’ wafer.

The result showed that the n-type Tiger Neo system is a better solution with higher production and with less land consumption. The cost figure found for the Tiger Neo array led to an IRR higher with respect to the other systems. Nevertheless, the Tiger Neo system has shown more economic and technical feasibility. As for the scalability of n-type capacity, the continuous reduction in system cost will further benefit the system.

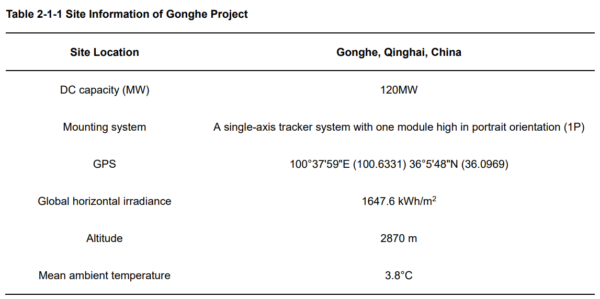

Location & Solar Resources

The plant is located in Gonghe, Qinghai (100°37'59″E, 36°5'48″N), with 120MW DC capacity. The mounting system is a single-axis system with one module high in portrait orientation (1P). The basic information of the site is as follows:

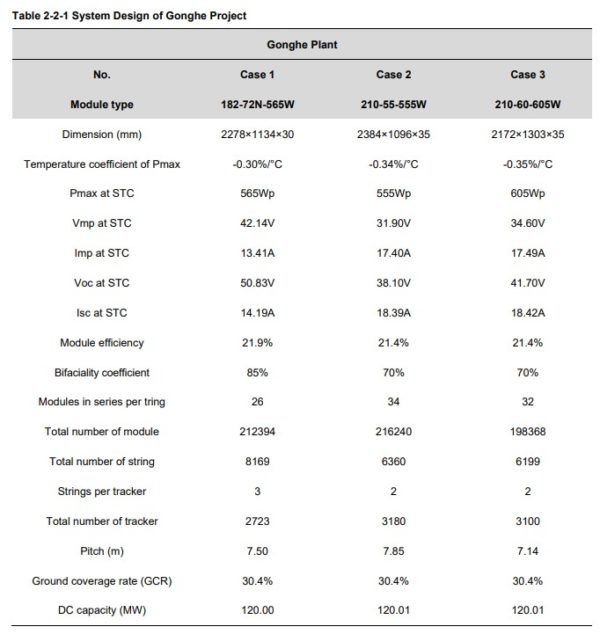

The Design Scheme

The PV plant land is considered as flat and suitable for large scale power plant construction (environmental and ecological impact is neglected), and the high voltage grid electricity transmission line is available near the site. Different cases in the project sites are assumed to be constructed in an approximately equivalent land area with similar DC/AC ratio, to diminish the energy yield difference. The basic information of the design is as follows:

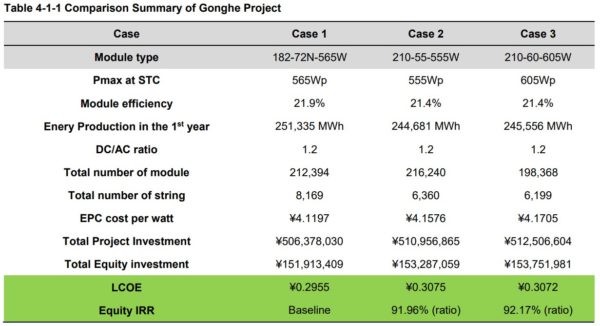

Levelized Cost of Energy(LCOE)& Internal Rate of Return (IRR)

When the unified DC side capacity, land availability, system design principles and module prices are determined, Jinko’s N-type TOPCon products have great advantages in terms of the cost per kilowatt-hour and profitability investment in large-scale ground power station project in Qinghai. The advantages of Jinko's N-type TOPCon modules are mainly reflected in:

- High-efficiency modules can greatly reduce the initial investment cost of the project (modules, BOS equipment procurement costs, EPC construction costs, etc.);

- It can save the use area of the plant, thereby reducing the annual land lease cost;

- JinKO’s N-type modules have a lower power degradation (1% in the 1st year, 0.4%/yr from the 2nd year), higher bifaciality coefficient (85%).

In the plant of Gonghe, Qinghai, China, thanks to the advantages of Jinko's N-type TOPCon modules, for instance, lower initial investment cost, reduced annual land lease cost and higher bifaciality coefficient (85%), the case that used N-type TOPCon module has the highest IRR, which is 13.79%, and the lowest LCOE, which is ¥0.2955.