Few months ago, the China Photovoltaic Industry Association (CPIA) published its latest guidance report, the “China's Photovoltaic Industry Development Roadmap 2020” (hereinafter referred to as “Roadmap”). In this Roadmap, CPIA provided professional suggestions for both China government and all industrial players on key concerns of the industry including market trend and future technologies. Within which, thinner wafer and two possible next generation cell techs, TOPCon and HJT, are presented, analyzed and discussed as focus due to the importance to the industry.

Firstly, thinner wafers could give higher conversion efficiency for solar cells due to better match to diffusion length of minority carriers. Secondly, thinner wafers appears their less fragility once the thickness gets down below 150beloum. Thirdly, thinner wafer apparently reduces cost of crystalline silicon, especially when in a supply shortage time. Currently, slicing technology supports thinner wafer well. Yet, limited by cell structure and respective panel encapsulation, thinner wafers of conventional solar cell would cause many issues in downstream process such as cracks, non-uniform resistance, hidden breakage, false welding and so on, and hit greatly to the yield of production. According to the Roadmap, CPIA expects 5μm thickness drop down every 2 years in future.

Meanwhile, as the potential of PERC cell is exhausted by endless pursuing for higher efficiency and this dominate cell technology is coming to its conversion ceiling now, the entire PV industry is expecting a king of next generation cell tech, very likely, one from HJT, TOPCon, or IBC, which are all with much higher potential conversion rate over PERC.

This highlighted the value of a special cell technology, the metal wrap through (MWT), which could be the better tech route along with the Roadmap of CPIA.

What is MWT?

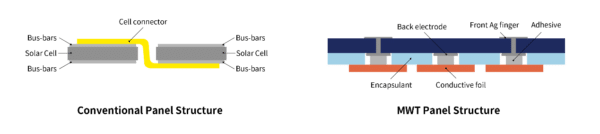

Different from conventional solar cell technology, the MWT technology is to transfer the current collected by fingers from the front side of cell to the back side through the silver paste, which is filled in tiny holes with around 120 μm diameter made by laser on silicon wafer. With eliminating the bus-bars on front side, light receiving area is significantly increased which result in direct improvement of panel efficiency. Meanwhile, silver consumption and minority carrier recombination loss at metal electrode/emitter interface are also greatly reduced.

There are several advantages for MWT over other alternatives. The non-bus-bars structure eliminates welding stress which might cause tiny cracks and do harm to panel performance. The encapsulation of the MWT cell to panel reduces series resistance and working temperature which is improving the panel reliability and more appropriate for ultrathin wafer application..

Among conventional technologies of solar cell and PV panel, the MWT is quite unique not only because of its technical characters, but also for its conjugation of cell and panel. MWT can be combined with other technologies like PERC, HJT, TOPCon, and etc., to achieve better efficiency. The technology is a mixture solution of solar cell and PV panel and this makes it difficult to handle for those only focus on cell or panel.

With high technical barriers there are not many manufacturers utilizing MWT technology around the world, only some locates in Europe, US and China. Among them, Sunport Power, a China Wuxi based leading cell and panel maker, is the only player with GW level MWT Photovoltaic panel supplement.

MWT fits thinner wafer

Benefits from the unique encapsulation structure, the MWT helps solar cell to utilize thinner wafer to 130μm or even less while keeps high production yield. According to Sunport Power, it has been successfully tested that the encapsulation of MWT panel can support super thin wafer with thickness of only 100μm, 43% thinner than current mainstream 175μm thickness. And the thickness they are using in their existing MWT + PERC production line as mass production output is with 150μm now and this will go to 140μm soon.

Combination with other cell tech

Considering the very close efficiency ceilings of these current techs, the winner might come from the best cost controller. As a conjugation tech of solar cell and PV panel, MWT can easily combine with most of other cell technologies including HJT and TOPCon.

Researchers of Sunport Power has successfully utilized MWT + PERC in mass production with almost the same yield of production as with PERC only, and even lower cost if with thinner wafer. The same as plus PERC, according to study by the Netherlands Organization for applied scientific research (TNO), the combination of MWT and HJT can increase total conversion efficiency by up to 4% compared to HJT only. MWT can also reduce the consumption of silver paste, which is a major cost factor for HJT process, and push the advantage of HJT to a higher level.

Conclusion

The Roadmap of CPIA has pointed out possible future tech routes. However, no matter whether TOPCon or HJT wins or both of them are applied, MWT will take the role of an indispensable assistant and, might become a real winner.

About Sunport Power

Jiangsu Sunport Power Corp., Ltd. was founded in 2012 in China and dedicated to R&D and manufacturing of solar cells and modules based on advanced MWT (Metal Wrap Through) back contact technology, committed to manufacturing of high-efficiency PV cells and modules, providing professional products, services and solutions for customers.