The quick-stop solution is becoming the choice of many countries, but how to balance economic and safety issues has also become the threshold for the popularization of quick-stop? On the premise of ensuring the safety, improving the power generation efficiency of photovoltaic power stations will be a better choice. Taking into account the market demand, Projoy has recently integrated the P2 series array-level rapid shutdown with PID repair function, which will improve the power station revenue!

The necessity of array-level rapid shutdown applications

Unlike module-level rapid shutdown, which can be precisely controlled to the shutdown of each module, although array-level rapid shutdown can only be achieved by cascade control, it still has its application necessity.

When the building installed with photovoltaic system is in danger, the rescuers can cut off the photovoltaic system through the array-level rapid shutdown of Projoy, and the high-voltage direct current will be isolated above the roof, and the roof will be in a relatively safe environment, creating space for fire rescue.

Generally, rescuers can cut off the system by disconnecting the AC power source. Projoy array-level rapid shutdown can collect the power-off signal, once the power-off time exceeds 5 seconds, it will automatically disconnect the internal isolation switch and disconnect the DC power source. The fault indicator can still keep the function of prompting for 3 minutes without AC power supply; if the AC power is automatically reset, the isolation switch will also be automatically connected after 3 minutes, then the array-level rapid shutdown will resume work.

On the other hand, there is an advanced temperature sensor monitoring the temperature inside the enclosure in real time. When the internal temperature exceeds 75°C, the switch will be automatically turned off. At the same time, when the internal temperature drops to 70°C, the array-level rapid shutdown will automatically reset and resume work.

Projoy has also been calling for the installation of rapid shutdown for photovoltaic systems in important public facilities such as schools and gas stations, the safety issues must be considered!

Continuously upgrade and optimize the rapid shutdown product line

As a global leader in rapid shutdown, Projoy has been paying attention to system safety issues and constantly innovating solutions since entering the photovoltaic field. According to market demand, Projoy has successively launched DC 24V power cable communication model and PLC power carrier communication model module-level rapid shutdown, all of which have passed UL1741 standard.

However, unlike many manufacturers, Projoy has never given up on the array-level rapid shutdown market, and always believes that this product has its due market demand. Therefore, the company will constantly optimize the product!

In 2017, Projoy launched 1-2 strings rapid shutdown for residential PV systems, and then quickly upgraded and released 3-5 strings rapid shutdown for industrial and commercial PV systems, 6-10 strings for large PV systems. Its maximum loop voltage can reach 1500V, which meets the requirements of high-power module.

In 2021, Projoy upgraded its first-generation array-level rapid shutdown, and launched the second-generation P2. It adopts an all-plastic enclosure design, so the product is light and easy to install! The wiring connection without opening the cover simplifies the installation process and improves the product life. At the same time, the FB1\FB2 function is added to facilitate the inspection of the working status.

This time, Projoy has launched an upgraded version of array-level rapid shutdown, which is also a safe and economical solution!

Superimposed PID repair function, safe and economical

PID effect which known as Potential Induced Degradation, is a phenomenon in which the performance of the module is degraded due to ion migration under the action of high voltage between the packaging material and surface material of the battery module, the battery sheet and its grounded metal frame.

At present, the reasons for the PID effect are different, but research shows that its occurrence is closely related to the component composition, packaging materials, temperature, humidity and voltage of the environment. Therefore, compared with ordinary power stations, floating power stations, fish-light complementary power station, photovoltaic power stations in coastal areas and near the equator are more likely to generate water vapor due to their humid and high temperature environment. Then the conductivity of the packaging material increases, and the leakage current of the corresponding modules increases, which is more likely to cause performance degradation, that is, the PID effect.

After research, most of the PID effects are reversible, in order to improve the economy of the power station under the premise of ensuring the safety of the power station system. On the basis of its P2 series array-level rapid shutdown released in 2021, Projoy has launched an upgraded rapid shutdown with PID repair function, which can effectively eliminate the potential attenuation of photovoltaic modules due to PID effects.

The PID module of the upgraded array-level rapid shutdown can apply a voltage between the negative pole of the photovoltaic module and the ground (PE) according to the DC input voltage for intelligent adjustment. At night, release the charge accumulated by the module during the day due to the negative deviation between the negative pole and the ground, in order to carry out repair work without affecting the normal operation and power generation of the PV power station during the day.

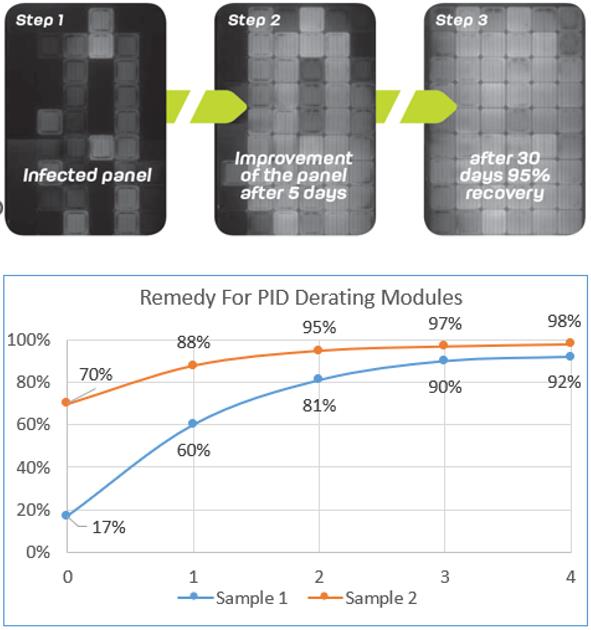

Through long-term experiments, we found that the continuous use of this rapid shutdown can effectively combat the reduction in the power generation of the PV power generation system caused by the PID effect. Among them, the power generation efficiency of module 1 in our experiment was increased from 70% to 98%, and the power generation efficiency of module 2 was increased from 17% to 92%.