Wrapping up this year's exhibition with Pfalzsolar

pv magazine just met with live sponsor Pfalzsolar CEO Lars Josten to discuss the company’s experience at Intersolar 2019.

pv magazine: We are now at the final hours of The smarter E exhibition. How has Intersolar been for you and are there any developments or announcements?

Lars Josten: There are some new market developments that have been surprising and it seems like there will be some great progress for us.

What market specifically are you referencing that comes as a surprise?

(Laughs) Well, it’s a Southern European country within the EU that is very sunny.

pv magazine has launched our UP campaign here at the show, where we are encouraging stronger sustainability efforts within the industry. What do you believe is necessary for the industry to lessen its ecological footprint?

It’s a hard question. The whole mindset of the entire population is changing. We are seeing growing numbers of demonstrations occurring globally, and just recently in the Netherlands, like the 30,000 people in Amsterdam, which are alarming. We are even experiencing this within in our company. A lot needs to happen internally with companies to meet the demands of the growing concern among the general population.

What is Pfalzsolar doing to encourage sustainability among the company culture?

We now have a biking scheme, where employees can rent bikes and within our company and we are paying for it. This encourages less driving and reduces pollution. We are buying things to reduce waste, starting with our kitchen, in the office, but at the same time on the construction. All waste is collected and separated.

Great, we are glad to see you are taking a proactive role. Are there any closing remarks on Intersolar that you would like to share?

It is a great time to be in solar in Europe. It has been a very positive Intersolar. Our company slogan is ‘We love solar’ and we stand behind this in confidence, in that you could really feel this at this year’s event. The market is progressing, we are seeing a lot happening across bringing technologies together, with solar and storage, and things will just continue to grow.

When is a European company not European?

With politicians in France, Germany and the EU hatching plans for a €5 billion battery manufacturing industrial base in Europe, one font of long established storage expertise may have been taken out of the continent two years ago.

Italian business FIAMM already manufactures batteries in Europe but the Vicenza-based company was snapped up by the Chemical business unit of global electronics giant Hitachi, with the Japanese conglomerate acquiring 51% of the Italian brand and due to complete a full takeover at some point.

At the FIAMM stand here, marketing and product manager Christian Confente told pv magazine the idea of backing storage manufacturing in Europe chimes with FIAMM’s approach. “The thought is the same,” he said, “we are aligned with this idea.”

The EU has big plans for its mooted battery industry

Which poses an interesting question for the policymakers pushing the Franco-German battery industry plan. How would they feel about the prospect of European expertise being involved with the project if it is owned by one of the companies which would be among the EU’s main competitors?

Judging by the response to questions about potential interest in joining the €5 billion scheme when pv magazine asked at the stands of German storage companies sonnen and Tesvolt, the EU might not be able to be too choosy about its partners, despite its confident talk about numerous interested partners.

Trade show representatives of both German companies at Intersolar politely explained the plan would not be relevant to them as they already source their cells from outside the EU.

Maybe FIAMM should stay by the phone anyway.

Schmid scaling redox flow in Saudi

Battery storage is nothing new to The smarter E. And nine out of ten battery integrators is deploying lithium ion cell technology, in its various flavors – particularly as cell producers continue to scale to meet the needs of the e-mobility sector.

German production equipment supplier Schmid hopes to give flow batteries a push in a major deal to establish a ‘GW-scale’ manufacturing facility in the Kingdom of Saudi Arabia.

Schmid has partnered with Nusaned Investment and RIWAQ. Nusaned is owned by Saudi petrochemicals giant Sabic – which is one of the world’s biggest chemical producers. And if flow batteries have any hope in competing against lithium ion and the car makers, scale is definitely required.

“We will be the first one who will have a fully integrated fab, to control the full value chain, which allows us to lower cost quite dramatically,” says Christian Schmid. “It’s been an issue of chicken and eg:, production volume is needed, as are optimised materials. In Saudi Arabia we can combine both with a partner from the materials side with strong R&D. Also the local market is growing, and its’ a country that is positive with opportunity to build up a world class battery fab,” he adds.

“The mix is pretty unique.”

Schmid’s technology is vanadium redox flow. The German company leveraged is experience in wet chemistry processes to develop its flow batteries The factor will occupy 70,000 square meters. It is being developed under a joint venture between the three companies and while Schmid won’t reveal what stake it has taken, it is “one of the biggest shareholders”.

ABBlockchain

Swiss power electronics giant ABB is showing that it can cut it with the fast moving startups of the blockchain space. At Intersolar the company announced a pilot program with an Italian utility and blockchain developer to integrate the technology into its inverters – to enable peer-to-peer (P2P) energy trading.

From ABB’s side, the challenge is to equip its residential inverters with the soft and hardware required to utilise blockchain technology – specifically its UNO-DN-PLUS inverters and REACT 2 hybrid inverters.

ABB’s Leonardo Botti says that it’s another demonstration of the rapid transformation currently underway in the energy sector. “There are three drivers that are ‘pushing like hell’ the change in the electricity system. These are distributed generation, storage, and e-mobility.” In all three, says Botti, digital technologies are key enablers.

ABB is partnering with Italian utility Evolvere. The blockchain being trialed was developed by Prosume.

“We are delivering an inverter with high level of computability – a small computer which does all of the calculations, generating reliable documents, and certificates [for the P2P electricity trading],” says Botti.

In terms of a wider rollout of P2P electricity trading, Botti says regulations need to catch up.

“There are a lot of steps to be made especially from a legislation standpoint. But legislation can always be changed if the technology is proven.”

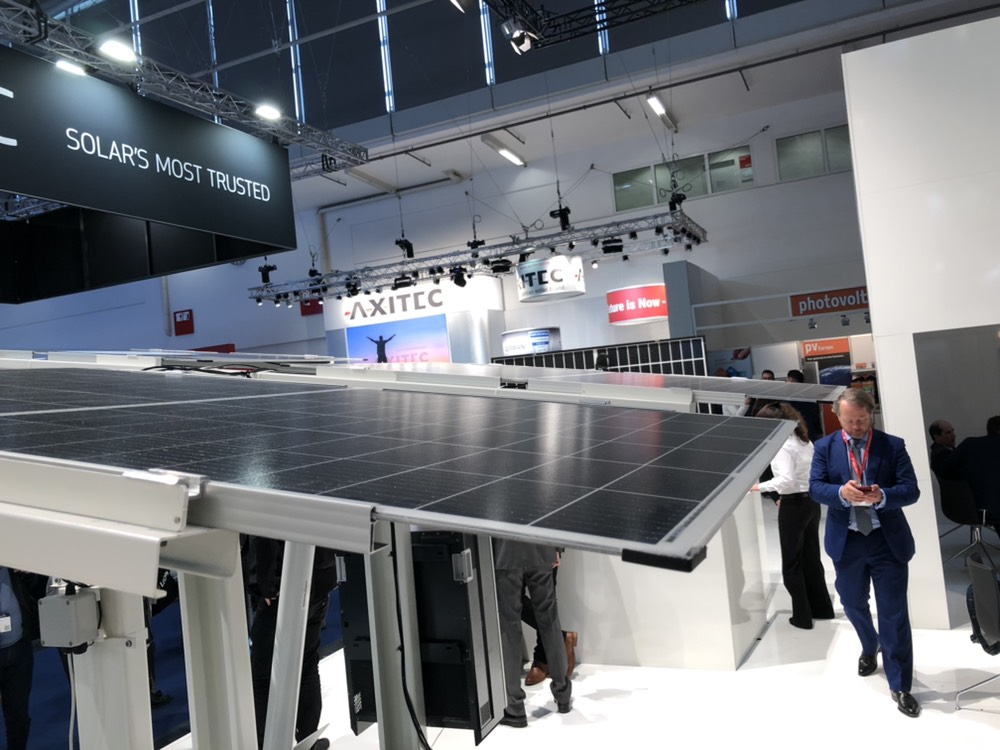

How are you showing UP?

Hanwha Q Cells' Ian Clover speaks with pv magazine about our UP campaign. We are working to drive accountability in sustainability for the industry… will you join us?

How are you showing UP? pv magazine is encouraging sustainability within and across the #solar and #storage industry. We caught up with Hanwha Q Cells’ Ian Clover at #Intersolar to discuss the #UPrising pic.twitter.com/rmRSBf6KuU

— pv magazine (@pvmagazine) May 17, 2019

SolarEdge set for battery production

“For customers that want a full solution, this is an excellent start” – as was pv magazine’s start to the day in the company of SolarEdge’s Lior Handelsman.

The inverter maker has moved beyond its traditional business in recent years and its offering now features UPS [uninterruptable power supply] systems as well as recent acquisitions in the e-mobility and storage sectors.

Still Open for business

A report in this morning’s Guardian newspaper quoted French finance minister Bruno Le Maire lamenting the fact the European solar panel industry has been “deliberately destroyed”, but pv magazine has caught up with someone who may take a different view.

Portugal’s Open Renewables has been manufacturing solar modules since 1994, using European cells until last year, although CEO Rui Lobo told pv magazine, it is not all plain sailing competing with Chinese competitors pumping out ever cheaper products in ever larger volumes.

“It’s hell on earth,” says the garrulous boss of the Evora-based business before explaining why the company now sources cells from Taiwan.

German factory closure

“We’ve worked with companies including Bosch and Solarworld and of course when we worked with them we used their cells,” he says. “There was another cell factory in Arnstadt [in Germany] that we were very comfortable working with but unfortunately they were shut down last year. That forced us to source cells from outside Europe for the first time but that’s the only component we source outside Europe.”

While Lobo gives the lie to Le Maire’s soundbite, he would surely acknowledge the politician has a point. “The European value chain of components and equipment manufacturing is not destroyed but it’s pretty wrecked,” says the CEO of a company which has an annual module production capacity of 60-80 MW. “We used to have a choice of three or four EVA manufacturers, backsheet makers, junction box makers – now you’re lucky if you have one.”

As a pioneer in a technology he believes will put us on the right path to combating climate change, Lobo was asked why it matters where PV panels are made as long as they are cheap enough to propel the energy transition.

Cheap but not cheerful

His response is forthright. “If you can source a system which is CO2 neutral,” he says, “why would you buy one with the equivalent carbon footprint of a diesel truck? You can manufacture silicon in Norway where 100% of the energy is green, from hydro, or in a country where the energy is coal driven.”

He also cites the added carbon burden of shipping Asian panels around the world, and touches on energy security issues too. “We don’t know exactly how our relations will be in the next 10 to 15 years,” he adds, with reference to the power blocs of Europe, China, Russia and the U.S. “The German people will remember the incidents with the gas supply [from Russia] some years ago, which gives a sight of what can happen when things go in the wrong way.”

It is a timely concern as geopolitical concerns mounted in the Persian Gulf this week but Lobo retains a sunny outlook regarding what he describes as the “gigantic” potential of the European market as well as new regions for his company to make its mark in.

Oman, Tunisia and Portuguese-speaking nations including Angola and Mozambique are of interest and with Open expecting shipments to rise this year, maybe Lobo can give Le Maire reason to have a slightly more optimistic outlook.

Generating downdraft

When it comes to rooftop installations, there are a few different ideas on how best to ensure safety and stability against wind.

Racking systems provider Aerocompact has various solutions on show this year, and says its design causes wind to push a PV system closer to the rooftop rather than lifting it and risking damage to the racking system or complete loss.

In spite of the design, though, Aerocompact sales manager Nico Baggen says he is skeptical of solutions which claim to reduce or eliminate the need for ballast on rooftop systems to anchor them. “We don’t just tell people to lift a lot of very heavy ballast onto a rooftop for fun,” he says, “there is actually a very good reason for this.”

Aerocompact has big expectations for the European market, with strong prospects in the Benelux countries – Baggen, who showed pv magazine around the company’s booth is sales manager for that patch – thanks to a booming market in the Netherlands where strong policy support is driving commercial rooftop installation.

Over at the CATL market

Contemporary Amperex Technology Limited (CATL), the world’s largest manufacturer of lithium-ion battery cells, is exhibiting in Europe for the first time here at The smarter E and its presence is a sure sign Europe can expect big things from energy storage technology in the years ahead.

While the bulk of CATL’s battery products are destined for electric vehicles, the company is keen to point out it is also a player in the stationary storage market – providing technology and working with integrators to put projects together – and has expectations of big volume projects in the segment, both in Europe and further afield.

While the representative pv magazine spoke to this morning wouldn’t be drawn on current projects or specific markets, CATL says Europe is a key market for its lithium-ion technology, and both electric vehicles and battery storage projects will play a major role in the energy transition.

Although it currently has no plans to expand manufacturing beyond its base in Asia CATL has not ruled out such a move in future.

Roll up, roll up!

One exhibitor at the show who opted against flashy, gleaming technology and eye-catching panel arrays was German company Valentin Software.

The Berlin based business correctly calculated that if you give visitors a target and a handful of soft balls to throw at it, they will be lining up.

And if show attendees have a steady enough hand and a sure eye, they can double the 15% Intersolar discount being offered on the company’s PVSol, TSol or GeoTSol products.

However, it is the opportunity to have new functions of the software explained by managing director Stefan Lindemann that may be the real prize.

PVSol, according to its developer, offers new opportunities to use geometric data to create a 3-D model and new, detailed options to replicate the energy consumption of appliances. For instance, groups of electric vehicles with different charging patterns can be visualized. The tool can also integrate data from heat pump designs generated from the GeoTSol solution.

That tool can now design heat pumps in cooperation with other heating systems and determines a performance rating based on field monitoring data from the Fraunhofer ISE, said Denis Dawes, of Valentin.

In addition, PVSol now also offers the ability to calculate the behavior of bifacial modules and back side yield. So you might want to get along and get your aim in.

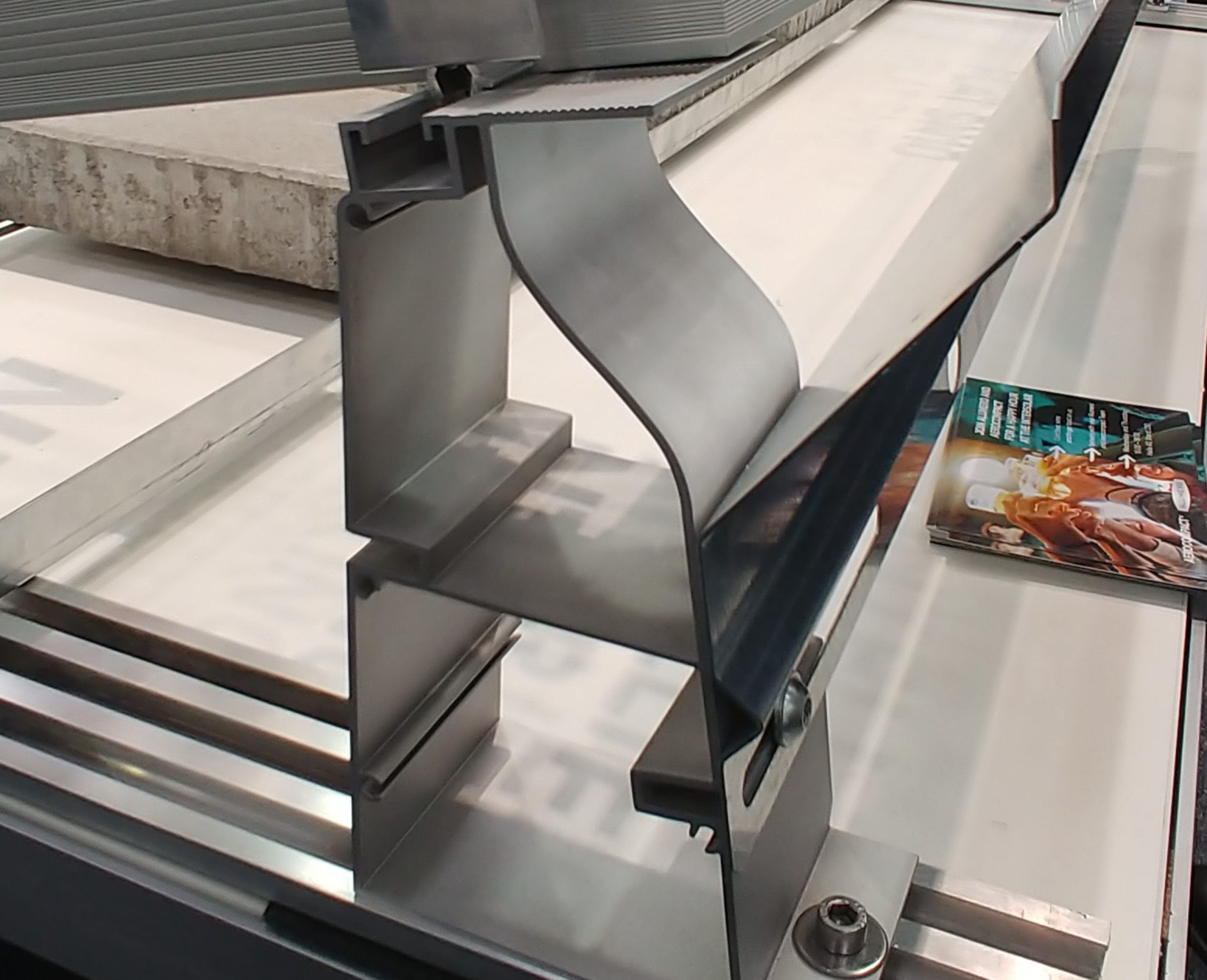

Break through the frame

Although you may have seen big tracker mounted PV installations as the tech grows in popularity around the world, what Trina Solar is demonstrating at its booth is slightly different.

Trina’s trackers slowly turn a short row of two-on-two modules back and forth – all very standard at first glance, but a closer look reveals the modules are different. The double glass product with half cells is not only bifacial but appears to be frameless.

However, with Winfried Wahl, chief engineer for rival manufacturer Longi Solar in Europe having railed against frameless models at this year’s event, the Trina product may not vex him as it only lacks a frame on its short side. On the long sides, two pieces of a frame are visible, even if they are cut off at the ends and in the middle.

Klaus Hofmeister, product manager for Trina solar, explains this is deliberate a feature of the new Trina Pro system. The modules with the breakthrough in the frame are only available for this tracking solution. Through the frame pieces, modules can be moved and clamped in the usual way but also have the advantages of frameless modules, ensuring water can drip off the edge and the bifacial back side is only slightly shaded.

The Pro system also introduces a new software solution that optimizes the yield of bifacial modules in tracking systems, with each row designed to optimize yield from the front and back. Plants with this solution can look quite irregular as a result, but there is an elegance about the modules that is evident upon closer inspection.

The morning after

Good morning readers,

Oh, the things I do for pv magazine. Last night I was forced to go undercover and attend the Sungrow Intersolar party, via BayWa re and somewhere else where the free booze was flowing. I may even (shudder) have danced. But it’s okay, I don’t think anybody noticed.

The pv magazine team, for the most part, were throwing themselves into the party with gusto on the dancefloor, as befitted the official media partner of the event. But we’re a hardy bunch at pv Towers and the staff will be pounding the floors again today mopping up the leftovers and last knockings from this year’s event.

The glitzy module launches and earnest roundtables may be over as things start to wind down, and the number of attendees queuing at the gates this morning was depleted but there’s still a hatful of the biggest names in the solar game here and we’ll be reporting throughout the final day.

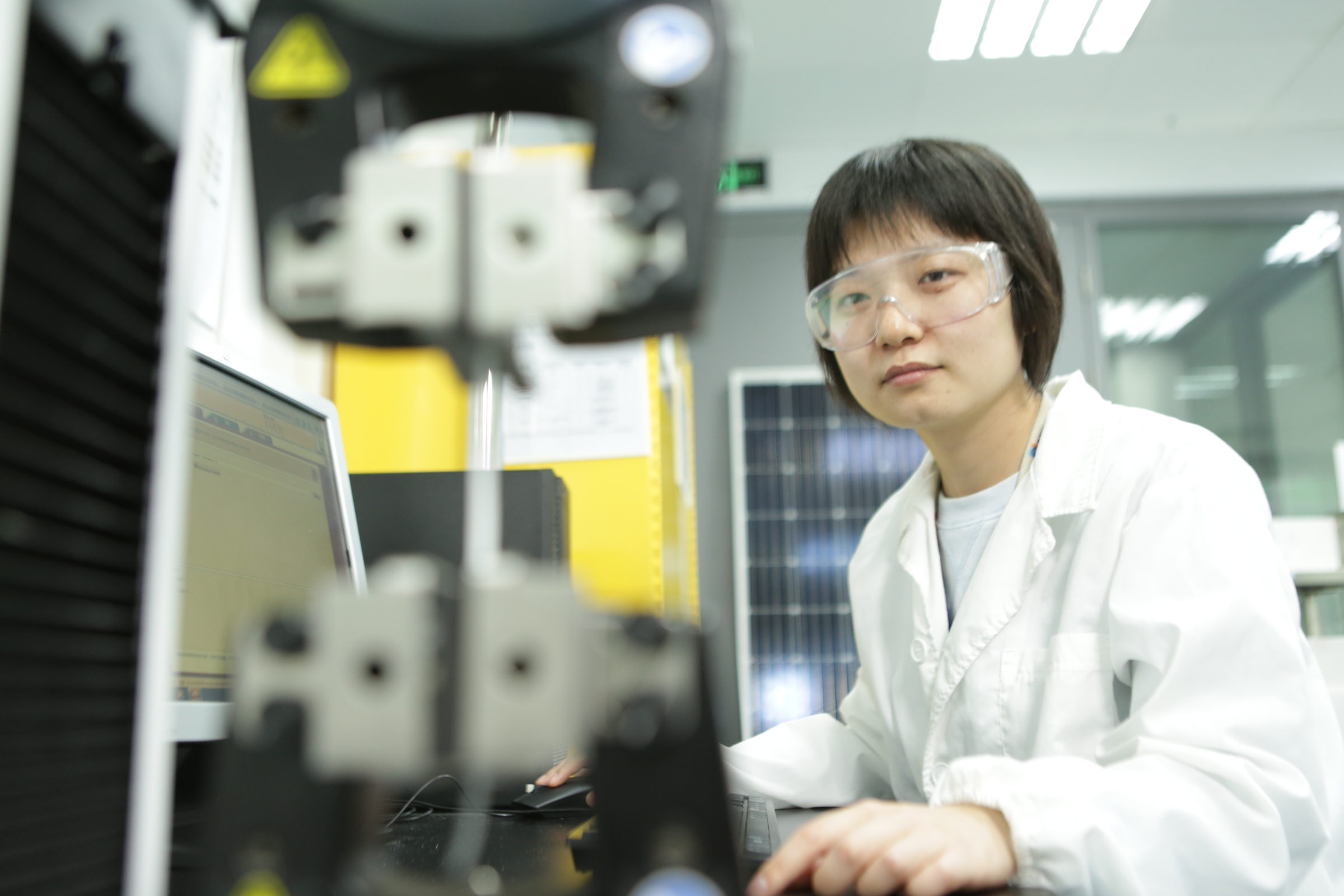

DSM’s circular solar ambitions

The notion of a circular economy is gaining traction, both in and out of the solar and storage industries. As part of our new UP campaign, pv magazine spoke with material solutions provider DSM Advanced Solar to see what it is doing in this area.

“We believe that companies have a responsibility to address environmental and social challenges, which includes sustainable use of the limited resources on earth,” said Imco Goudswaard, sustainability manager.

WE LOVE SOLAR… and electric scooters. Last chance to win yours!

As Intersolar nears its closing, today is your last chance to meet with pv magazine live sponsor Pfalzsolar at this years’ event. Visit www.welove.solar to enter into their giveaway to win a FREE electric scooter – and schedule a last-minute appointment. The winners of the two free scooters for this years’ event will be announced at 2PM. Meet on site to collect the prize before leaving Munich, and cruise home in smarter E style!