EUPVSEC: Cautious optimism over local production

As the 40th edition of the European Photovoltaic Solar Energy Conference and Exhibition (EUPVSEC) gets underway in Lisbon today, it’s clear that European PV manufacturing faces some difficult challenges in the current climate of low prices and strong competition on all sides. Nonetheless, the show is already revealing plenty of optimism among the continent’s PV manufacturing players.

Accelerated testing procedures for perovskite solar cells

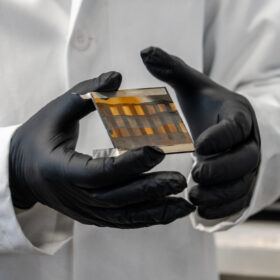

Scientists in the US developed a series of accelerated testing procedures designed to predict how perovskite solar cells will perform when installed outdoors for a long period of time. The study finds that combined, simultaneous exposure to light and heat gives the most accurate of how a perovskite solar cell will perform in the field.

New silver paste product promises TOPCon solar cell gains

China’s Solamet has launched a new silver paste product for tunnel oxide passivated contact (TOPCon) solar cells processed with laser carrier injection technology. By solving a problem related to contact between the paste and the boron doped front surface of the silicon cell, it promises an efficiency improvement of at least 0.2% over competing products.

Greenpeace notes widespread greenwashing among fossil fuel companies

A new report published by environmental campaign group Greenpeace analyses financial statements from 12 major European headquartered oil companies. The study finds that, despite many public claims to be participating the energy transition, both the current activities and future investment plans of these companies are dominated by fossil fuels.

Quantum physics, supercomputers, and solar cell efficiency

Scientists in the United States applied quantum computing techniques to the study of singlet fission – a little understood phenomenon that carries the potential to greatly increase solar cell efficiency. For now, the study reveals more about potential applications for quantum computing than for solar cells. But the techniques demonstrated could eventually helps scientists identify better materials for highly efficient solar cells.

Cracked cathodes not all bad, battery scientists find

Scientists in the United States developed an innovative method to observe the inner workings of lithium-ion batteries and found that cracks which form in the electrode – something manufacturers do their best to minimize – may actually have benefits in allowing for faster charging. The work also challenges assumptions on how certain particles behave inside a battery, with potential consequences for their future design.

Laser optimization for half-cut solar cells

Scientists in Korea examined the parameters of laser ‘scribe and break’ processes used to cut silicon cells, in search of optimizations to reduce damage caused at the cut edges. They also found that varying encapsulant thickness or even adding a supportive rail across the back of a module can help reduce performance loss caused by cell cutting damage.

RENA announces 1.8 GW sale for new TOPCon equipment

German company RENA Technologies has announced the first sales of a new tool for silicon cell manufacturing. The tool is used for etching/removal of unwanted material on one side of a solar cell, and will be integrated into the gigawatt-scale production of an unnamed manufacturer in South Asia working with TOPCon technology.

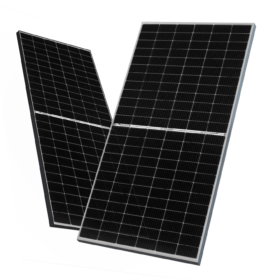

TOPCon PV modules outperform PERC by more than 5% in energy yield tests

A study by TÜV Nord in Malaysia shows that the latest generation of tunnel oxide passivated contact (TOPCon) modules surpass their older rivals on energy yield. The researchers compared n-type TOPCon modules with older p-type PERC modules, both manufactured by JinkoSolar over a three-month period earlier this year. The newer product showed an energy yield 5.69% higher than its PERC counterpart.

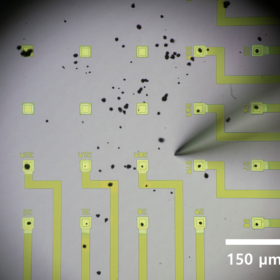

Using shunts to spot PV module degradation

Scientists in Ireland investigated the effect of shunt resistance on a PV cell’s electrical performance. The group says its finding could potentially lead to the development of models for early detection of various forms of cell degradation, allowing for intervention to repair or replace components before major power losses occur.