A gulf between PV ambition and testing facilities

Though it already hosts several of the world’s largest PV installations, the Middle East and North Africa (MENA) region’s solar industry is still young, with limited local infrastructure and expertise. Project developers are learning quickly that building PV in harsh desert environments requires a careful eye on quality. New testing laboratories are looking to meet demand.

‘Oversupply issues may continue in 2025’

As part of our Intersolar 2024 interview series, pv magazine spoke with Amy Fang, senior PV analyst at InfoLink Consulting, about new solar factories coming online and decreasing solar modules prices. She says the downward trend may continue until the first half of next year, with prices reaching $0.07/W, and estimates global module demand for this year could reach between 470 GW and 500 GW.

‘We expect solar panel prices to stabilize in the second half of the year’

At Intersolar Europe 2024, pv magazine spoke with Edurne Zoco, executive director, Clean Energy Technology at S&P Global Commodity Insights, about module price trends, increasing solar demand and PV manufacturing outside China. She claims panel prices may stabilize in the second half of this year or in early 2025 and says top seven Chinese manufacturers may even continue with capacity expansion plans. She also believes that, without further substantial incentives, Europe will not be able to recreate a domestic PV supply chain.

Access to finance key for solar in small island nations

Held once a decade since 1994, the fourth International Conference on Small Island developing states (SIDS) began this week in St. Johns, Antigua and Barbuda with a strong message: That major changes to international finance are needed to create a level playing field for sustainable development in the world’s island nations, and that larger nations and industries bear responsibility for the impacts of climate change, and must do more to honor commitments towards their mitigation.

Building back bigger

Already 2024 is shaping up to be another record year for solar installations. In Europe, projects are getting bigger as increasing difficulty with obtaining a grid connection makes smaller systems unviable. pv magazine recently caught up with Bernhard Suchland, CEO of Germany/Bulgaria based project services provider Sunotec, for a look a closer look at this and other trends in the large-scale PV segment.

Key takeaways from SunRise Arabia conference

Saudi Arabia has laid out an ambitious vision to establish itself as a renewable energy hub for the Middle East and beyond. The market is growing rapidly, with solar generation capacity more than tripling in 2023. But obstacles remain for the Kingdom to continue on this PV pathway, and these challenges were up for discussion this week in Riyadh at the SunRise Arabia conference, organized by Solarabic and pv magazine.

Weekend Read: Temper tantrum

Reports of broken module glass with no obvious cause have begun to crop up at large PV projects. Module design, glass manufacturing, and interactions in the field between modules and trackers are at play and a clear solution has yet to emerge. Early signs suggest an update to certification standards may be needed.

Integration on hold: Energy Taiwan 2023

This week, pv magazine was in Taipei for the Energy Taiwan exhibition. The island is moving forward on net-zero ambitions and hosts a renewable energy industry ready to support other companies in achieving them. There is much focus on energy storage and grid integration, as Taiwan looks to create space in its grids for more renewable energy. However, with elections upcoming in early 2024 and one party likely to favor nuclear over renewables, many projects are now on hold.

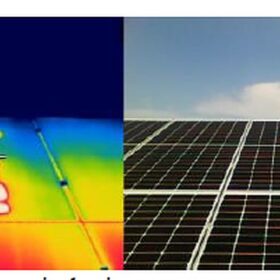

Combination of half-cut, bifacial solar cell designs may contribute to hotspot formation

Scientists in Spain tested PV modules under partial shading conditions, aiming to better understand the formation of performance-damaging hotspots. The study reveals a potential issue particularly affecting half-cell and bifacial modules, which may cause accelerated performance loss and is not covered by current testing/certification standards.

Solar energy in the real world – EUPVSEC 2023

Practical matters, beyond simply improving on solar cell efficiency, have led the agenda at the European Photovoltaic Solar Energy Conference (EUPVSEC) going on this week in Lisbon. Policy and the geopolitics of solar manufacturing is the big question on everybody’s lips as the event passes its halfway point today. Concerns including grid integration, critical materials consumption, and public acceptance are all being aired frequently – illustrating a closer than ever link between work being done in the labs at solar energy institutes and the everyday lives and energy consumption of people in Europe and around the world.