Eco-friendly solvent for a 16.7% perovskite solar cell

Scientists in Germany looked to eliminate the use of toxic solvents in the production of perovskite solar cells, replacing them with a more environmentally material called dimethyl sulfoxide (DMSO) which has so far proved difficult to integrate into processes suitable for large-scale production. The group demonstrated a scalable blade coating process using DMSO as the only solvent, and reached cell efficiencies close to those achieved using more toxic substances.

Role of UV in solar cell degradation

US scientists have tested a range of modern cell designs under strong ultraviolet light and have found that many of them, including p-type PERC and n-type heterojunction cells, are more susceptible to degradation than older back surface field designs. They noted that the rear side of bifacial cells may be particularly vulnerable.

Environmental impacts of perovskite PV

A life-cycle analysis of perovskite-silicon tandem modules indicates that additional environmental impacts in manufacturing are more than offset by the higher energy yield over their lifetime.

Femtosecond lasers for high-efficiency organic PV

UK scientists have developed a process using laser and x-ray pulses to observe what happens in the initial fractions of a second after light hits a solar cell. By applying the technique to various organic PV materials, they expect to gain insights that could quickly the improve the efficiency of such materials.

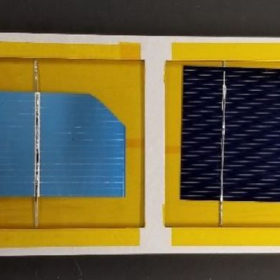

Recycling process promises ‘better than new’ silicon wafers

Scientists in China have developed a new recycling process for PV modules that can recover intact silicon cells from end-of-life products, and process them back into wafers. As part of the recycling process, the wafers are purified and surface-treated, making them suitable for integration into new, high-efficiency cells and modules.

Vehicle integrated solar to power refrigerated trailers

German VIPV specialist Sono Motors has signed an agreement with French refrigerated vehicle supplier Chereau to develop refrigerated vehicles powered by an integrated solar array. The two companies will build and test a prototype vehicle, and begin to evaluate mass production. Sono estimates that the concept could save around 3,400 liters of fuel and avoid 9 tonnes of CO2 emissions per vehicle, per year.

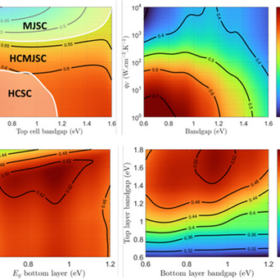

Reaching beyond efficiency limits

An international group of scientists experimented with a concept known as a “hot junction” carrier cell, which holds the potential for efficiency beyond the theoretical limits assumed today. The group modeled various cell designs, seeking those that would be least affected by imperfections in the actual materials, compared to how they are modeled.

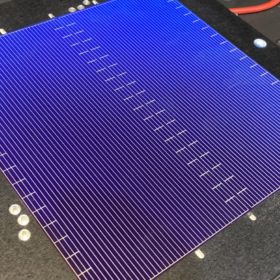

Cutting out cadmium for a 16.7%-efficient flexible thin-film solar cell

Scientists in Japan have developed new processes for CIGS solar cell manufacturing, entirely eliminating the use of cadmium and replacing a waste-intensive wet chemical stage. With a thin film deposited on a flexible steel substrate, the group achieved 16.7% efficiency, which it says is a record for a cell of this type produced using scalable fabrication processes.

Tuning out the defects for more powerful perovskite solar cells

Scientists in the UK and Japan used the latest imaging techniques to observe the inner workings of a perovskite solar cell at the scale of a few nanometers. Their findings suggest that a single defect is responsible for both limiting initial performance and causing degradation of the cell. By altering chemical compositions and process parameters, the appearance of this defect can be quickly reduced, and the group is confident that its finding could quickly be applied in large-scale processing as well.

Gallium doping and solar cell degradation

German scientists have conducted a series of experiments on gallium-doped silicon solar cells to understand the causes of degradation in PV cells and modules treated with gallium rather than boron. They confirmed that the performance losses are caused by a bulk defect in the material, and found that the right combination of light and temperature can “heal” earlier damage and even lead to small improvements in overall cell efficiency.