The trend towards portfolio consolidation is accelerating in the U.S. solar industry, whittling down the number of firms managing solar assets. Larger portfolios of solar PV plants create market efficiencies, but, depending on their geographical distribution, they may also create new operational challenges. Financially combining diverse assets means that outlier projects far below projected energy production can have a severe impact on a portfolio’s target rate of return.

The size of these new aggregated portfolios has magnified the standard operations and maintenance (O&M) issues. Facing the daunting task of juggling multiple monitoring platforms to assess site performance and project health creates a challenging and inefficient business environment for both asset managers and O&M providers.

The industry’s top 10 players manage more than 50% of the installed base in the U.S. Asset management software firms are responding with capabilities that cater to these companies with combined portfolios, but often neglect the needs of the O&M providers.

Streamlined knowledge is power

Aggregating PV projects comes with some baggage —sites designed by different firms with different design goals vary greatly in terms of operation. New asset owners inherit not just a different asset but often a different monitoring system. While it is possible for asset managers to use several types of software across a portfolio, it is neither convenient nor effective when tackling on-site issues. Inconsistencies in both recorded data points and data resolution are major hurdles for a job whose goal is efficiency and consistency. Acquisitions and project sales create a minefield of complex challenges for asset managers to resolve.

Standardized asset management technology is a cure for some of these headaches, helping portfolio owners to organize financial information and record keeping. Using a unified software platform with remote monitoring and controls creates data consistency across projects and can enhance efficiency, reduce labor, and lower the levelized cost of energy (LCOE) of PV assets. These efficiency gains can help accelerate portfolio growth.

System downtime and suboptimal operation produce the greatest losses for total system performance and return on investment. Traditional diagnostic methods have historically involved long response times and costly labor. Conventional site health diagnostics require expensive truck rolls and can keep arrays offline for over 24 hours, incurring unrealized PPA revenue. While truck rolls are key for general system maintenance, remote monitoring software can support asset managers by limiting labor deployments to an as-needed basis.

High quality and consistent data across an asset owner’s portfolio can drive targeted and efficient maintenance and diagnostic procedures. Asset managers can use performance models to assess the relative liability of the site issue and determine whether maintenance could be delayed until a larger issue presents itself. With a view across the portfolio, O&M providers can consolidate truck rolls across multiple sites and deliver maximum efficiency for costly site visits.

The flexibility of remote monitoring technology offers both convenience and predictive power. Asset managers can assess system power output in real time virtually anywhere with an Internet connection. In the case that actual performance differs from the predicted performance modelling of a PV site, asset managers can use next generation diagnostics to evaluate site health and the possible variables that are impeding the array from hitting projected targets. PV performance can vary for a variety of reasons: be it losses caused by location characteristics, weather events, site degradation, or component malfunctions. Monitoring software can provide insights into which sites perform best within a portfolio and why. These patterns and lessons can inform new construction of PV as an increasing number of Fortune 500 companies look to engage in the power markets by generating and consuming their own power or engaging in PPA agreements.

More than monitoring

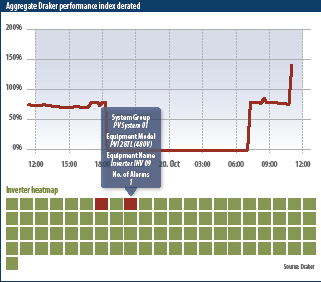

Consistent information is one part of optimizing PV performance, but the latest wave of monitoring software is also a platform for action. In the case that system equipment fails, some PV monitoring solutions offer remote on/off control capabilities to avoid or defer on site maintenance. Visualization tools like inverter heat maps enable sites with hundreds of string inverters to be managed conveniently. The heat maps can be complemented by the ability to actually turn that faulty inverter on or off from the comfort of your desk. Each avoided truck roll means more avoided cost. Depending on the severity of the issue, allowing corrective and reactive maintenance to be done remotely preserves budgets for high priority maintenance tasks in the future. According to NREL, more efficient planning and delivery of O&M can reduce the variability of these costs, previously ranging between $0 and $40/kW per year, to a more uniform $10/kW per year.

There are other benefits of remote monitoring and control software. Take for example, a major home furnishing retail giant that has deployed PV assets on a number of its retail facilities across the U.S. At a site in Columbus, Ohio, the company is required to meet utility limitations on the amount of power that can be generated by the array. To accommodate these requirements, the asset managers implemented customized control strategies from our firm, Draker, to curtail the amount of power being produced on-site. In areas with high renewables penetration, utilities are forced to curtail PV generation to maintain grid reliability. Utilities use either SCADA solutions or manual remote controls to take sites offline as a means to balance supply and demand on the grid. Solar PV owners need to be prepared for how this affects their assets.

To ensure that the site is producing energy year-round, the retail site asset managers can monitor and change the output of the project based on seasons, building load and changing utility requirements through an integrated cloud-based monitoring and control solution. Of course, having remote control abilities requires enhanced security and operations that must be intricately logged. The logging also creates a unified ledger for projects that can be used to inform future design decisions. In a portfolio that stretches across the country with varying state regulations and utility requirements, having remote control ability through a single portal is a powerful tool for managing those assets.

Commercial power generators who consume the electricity produced by their PV assets also require an increased level of customization when monitoring their portfolios. In the case of the Columbus site, an accelerated build schedule resulted in a project that was fully commissioned in under six weeks. Upon completion of the hardware installation, the site was accessible through cloud-based software within 24 hours. The retail chain continues to leverage remote monitoring to control its PV assets across the country and maximize power production.

The trend towards consolidating solar assets is accelerating, and large developers and EPCs continue to gain market traction. Remote monitoring provides asset managers with a standard platform to aggregate and evaluate data. Monitoring and control platforms have improved the challenging O&M landscape by providing tools to compare production estimates with actual yield in real time. By assessing environmental and operational conditions, asset managers can minimize downtime and prevent system performance losses. As consolidation continues across the PV supply chain, O&M providers and asset managers increasingly need to standardize their software. It’s a clear path to maximize return on investment across portfolios and inform the development of future deployments of solar PV. In essence, a bigger machine needs better support to run more efficiently.

Author: Joe Grimes

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.