A+SunSystem

SunNet Ground mounting system

A+ Sun Systems is introducing its Sun- Net Ground, a steel cable mounting sys- tem for ground-mounted photovol- taic plants. It consists of steel wire ropes anchored at the extremities, offering an easy way to increase the tension, and a special hook, which the company states is a breeze to install. Because the mod- ules are suspended on cables, they can cover extremely irregular surfaces such as curved landfills, steep hilly quarries, or agricultural land in which it is undesir- able to forfeit land area to mounting structures. The modules can even be suspended over water.

In standard ground applications, accord- ing to A+ Sun Systems, tensile cable rack- ing offers the opportunity to have much larger spans between posts, reducing installation cost, and resulting in up to 65% weight reduction. Having thin wire rope and few easels under the panels, the racking system opti- mizes performance of bifacial PV panels. A+ also notes that SunNet Ground can be used with trackers.

____________________________________________________________________________________________

Ecoppia

T4 autonomous cleaning robot

Ecoppia’s T4 module cleaning robot is an autonomous, water-free cleaning solution for utility-scale, single-axis PV installa- tions using SAT technology. The robot removes 99% of dust from the panels in a nightly automated cleaning opera- tion of up to 400 m2 – or approximately 200 modules. Cleaning is done when the modules are in a stow position with an angle of 5 degrees or fewer. The mecha- nism of action is a combination of rotat- ing microfiber cloths coupled with con- trolled airflow.

No human operator is required and the robot will do its thing without human intervention. It detects the edges of the structure with sensors and integrated technology, and then navigates along the most optimal and efficient pre-defined path. All T4 units are centrally controlled and managed via a cloud-based network with data securely stored on Amazon.

A key benefit is that it allows nightly cleanings. Further, the company states it uses advanced predictive maintenance technology and smart heuristics to determine the optimal time to clean. Finally, it uses no water, which means it is ideal for arid regions in which water is scarce and very often sunshine is abundant.

____________________________________________________________________________________________

OMG Roofing Products

PowerGrip rooftop attachment anchor

PowerGrip Universal is a roofing anchor for racking systems. It aims to reduce three things: the need for ballast, weight on the roof, and labor in installation. The anchor delivers up to 3,300 lbf (13.34 kN) of tensile strength, 2,500 lbf (11.12 kN) of shear strength, and 2,000 lbf (8.9 kN) of compressive load strength.

The base ring is secured through the roof- ing cover and into the deck, with a water- proof cover plate. This mode of attach- ment transfers much of the load to the structural roof deck without any weld- ing. Further, the company states its prod- uct is typically installed in fewer than five minutes.

____________________________________________________________________________________________

Anar Solar rack and ballast

Anar Solar rack and ballast

Anar solar’s system for racking and ballast aims to reduce installation time and costs associated with site preparation, and make solar viable on slopes, landfill sites, and other less than optimal land types. The solution relies on HDPE tubing filled with ballast material, which also acts as a conduit for all cabling. The tubing, says Anar Solar, can be aligned at less than 33 degrees between land contours, mak- ing practically any piece of land viable for a solar installation. The tubing attaches to

Anar Solar’s racking system via clamps. The racking supports 20 panels in land- scape orientation at between three and nine feet (0.9-2.7 meters) of elevation. The company notes that its solution elimi- nates the need for flat terrain. The system uses slots and pins, and Anar Solar states that installation time is 45 minutes per 20 panel array for two workers.

____________________________________________________________________________________________

Energyra

Energyra PERC MWT module

Energyra is bringing its new factory online in the Netherlands, where it plans to pro- duce a module which combines high efficiency mono-PERC cells with ECN patented metal wrap through (MWT) technology. All while using reclaimable, traceable, and quality materials.

The 60 cell module has a peak range between 295 and 320 W of output, and thanks to MWT technology is busbarless – allowing for 3% more active cell area, and better resistance to microcracks, when combined with the patented EBfoil conductive backsheet. According to Energyra, the module also boasts a lower temperature coefficient, through the EBfoil heat dispersing alu- minum copper layer.

____________________________________________________________________________________________

Power Panel

Power Panel solar thermal panel

Solar modules have one self-defeating drawback: Their performance diminishes as they are heated. The hybrid technology behind Power Panel seeks to offset this by integrating solar thermal heating into the back of a solar PV module. Such a design allows the Power Panel to capture up to 75% of incoming sunlight into usable energy, both as electricity and heat – PowerPanel states that the product can efficiently heat water to 158 degrees fahrenheit (70°C). The company also states that the payback period for its product is typically less than five years. The panel utilizes monocrystal- line cells, which are first interconnected and then placed on top of a heat absorber layer coated with an encapsulant.

____________________________________________________________________________________________

Solytic

Monitoring and analytics solution

Devising a data-driven algorithm, Solytic offers a platform combining Internet of Things and artificial intelligence to assess large data sets on system performance. The software sources detailed metadata like geo-location and string plans, and creates a ‘digital twin,’ determining the highest theoretical generation capacity. This way, operators can establish if their asset is underperforming, and also see where exactly the fault is occurring. While a few years ago O&M contractors could charge two-digit euros per kWp for accessing and analyzing historical data, Solytic offers a more attractive introduc- tory product for €0.20/kWp/year.

____________________________________________________________________________________________

Megger

DET

2/3 advanced earth/ground tester

Utility-scale assets require testing for ground protection, to reduce risk of fires and to meet lightning protection standards. Megger’s tester can provide high resolution ground current data in a robust, compact, and practical unit. Megger reports that the DET2/3 brings together a number of ground testing tech- nologies into one device.

This allows it to evaluate ground commis- sioning of electrodes, measure soil resis- tivity, and test for ground maintenance requirements, all in one device.Megger claims the device is the first to carry out all tests with the one instrument – while providing live graph reading dur- ing testing. The package comes with a two year guarantee.

____________________________________________________________________________________________

Sunto

CaptPro

Plus 300%, 10×, and 1%: These are the headline figures spelling out the advan- tages of Sunto’s CaptPro – a new approach to irradiation sensors. A 300% increase in accuracy, 10 times more precise local- ization of faults, and the ability to detect production decreases from as little as 1%. Sunto says this can deliver a power output increase of up to 5%. While the claims are staggering, there are indications that the CaptPro truly repre- sents a step-change technology for irradi- ation sensing. The device is a single wire- less, self-powered, and robust unit – with no moving parts. It can measure global, diffuse, direct, and ground-reflected solar irradiation, replacing pyranometers, pyr- heliometers, and a tracker.

____________________________________________________________________________________________

REM Tec energy

Agrovoltaico greenhouse

Italy’s REM Tec has developed a solar tracking greenhouse concept, which opti- mizes electricity production with grow- ing conditions for crops underneath. The Agrovoltaico dual-axis tracking platform is the primary technology behind the con- cept, in which 12 meter module rows sit 4-5 meters above the ground, providing sufficient clearance for crops to prosper below. Additionally, the system is designed to minimize shading of the crops.

The Agrovoltaico Greenhouse concept adds software to the system. While tracker backtracking algorithms are commonly optimized to maximize output from the array, the REM Tec package is designed also to optimize the growth conditions for the plants within the greenhouse – controlling variables such as air conditioning, shading nets, artificial lights, ventilation, water recycling, irrigation, and energy storage, whether electrical or thermal.

____________________________________________________________________________________________

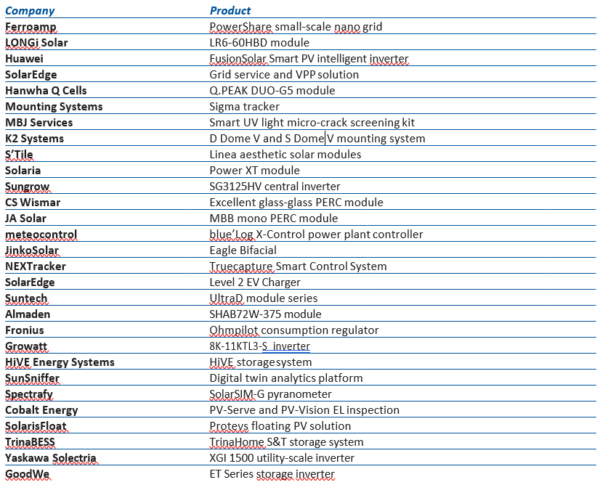

On top of these 10 new products, pv magazine’s expert jury rated the following list of innovations from across the sector, which were originally featured in the June edition of pv magazine, ahead of Intersolar Europe in Munich.

____________________________________________________________________________________________

The Array Changing jury

Dirk Morbitzer

Supply Chain Manager, Sunrun

While based in the U.S., Dirk has a long history in the European solar sector. Dirk is a two-time Array Changing Technol- ogies juror. At Sunrun, he is responsible for the vendor selection, contract negoti- ations, and quality management.Dirk is constantly evaluating new tech- nologies in terms of their impact on cost, reliability, and usability. During his more than 10 years in the solar industry, Mor- bitzer was Managing Director at Renew- able Analytics, where he advised finan- cial investors on renewable technologies, Director Global Procurement at Trina Solar, and Head of Procurement at S.A.G. Solarstrom.

Anika Giller

Senior Business Development Manager EMEA & APAC, Clean Energy Associates

Anika leads Clean Energy Associates’ (CEA’s) business development initiatives for clients in over 15 countries across Europe, the Middle East, and Africa, as well as in the Asia Pacific region. She man- ages a cross-function team in Italy, Spain, India, China, and the Philippines to execute client engagements. Prior to joining CEA, Giller worked in a cleantech startup and at IT and marketing advisory firms in Germany. She holds a BSc (Business Administration) from the Free Univer- sity of Berlin, and a MSc (International Business Administration).

Paula Mints

Founder and Chief Analyst, SPV Market Research

Mints began her career in 1997 with Strat- egies Unlimited. In 2005 she joined Nav- igant, where she continued as Director in Energy Practice until October 2012, when she founded SPV Market Research. Mints’s areas of expertise include: global markets and applications for solar prod- ucts, cell and module cost and price analysis, system and system component analysis (including inverters, trackers, and other BOS components), and trend analysis.

Chakradhar Byreddy

Chakradhar Byreddy

Director, Renewable Energy, UL Asia Pacific

Byreddy leads the testing, inspection, cer- tification, and advisory operations in the wind, solar, and battery storage industries. He also heads UL’s efforts for stakeholder engagement in renewable energy, includ- ing various government ministries, regulators, and industry associations.

A technical and technology expert, Byreddy has over 15 years of experience in application of engineering and next-gen- eration technologies in the clean energy, oil and gas, and aerospace segments. He has worked with different private equity, debt financing, and insurance organiza- tions on their financial modelling and assumptions to understand project risks in the areas of wind and solar. His previous engagements include China headquar- tered Envision Energy, Norway-based quality assurance and risk management company DNV GL, GL RC, Vestas Ameri- cas, and Baker Hughes Americas.

____________________________________________________________________________________________

After examining more than 40 entries over several hours of deliberation about the winners, our four independent industry experts have singled out the following five innovations as having truly array changing potential.

Joint winner: NEXTracker TrueCapture | Joint winner: Ferroamp PowerShare Highly commended: Cobalt Energy PV-Serve and PV-Vision

Finalists: Stäubli Power-Blox | Hanwha Q Cells Q. Peak Duo-G5

Congratulations to all of the five finalists who will go on to be included in the running for the inaugural pv magazine Award, to be announced later in the year. pv magazine would like to thank our expert jurors for their time, and all who made a submission for sharing their latest developments with us. The competition was stiff, and we are proud to be part of such an innovative industry.

![]()

Joint winner: NEXTracker

TrueCapture tracker control system

U.S. tracker supplier NEXTracker has been chosen as a winner of Array Chang- ing Technologies thanks to its ability to boost power plant yield, and to compen- sate for terrain, shading, and other factors. NEXTracker states that its TrueCapture system can increase plant yield by up to 6%. It does this by drawing from the latest meteorological forecasts on diffuse light conditions such as clouds, fog, or pollu- tion particulates. Then its self-learning algorithm corrects panel direction to minimize production loss due to inter-row shading and clouds. Further, the system has smart panel sen- sors that provide real-time sensing information on each tracker row’s shading and light conditions. The approach is unique due to the incor- poration of machine learning algorithms. These improve system behavior over time and let it adapt to local conditions.

Jury comments:

“There is a verified gain in production: an absolute gain averaging around 4%, which is huge.”

“This sort of nuanced change is what tech- nology advancement is. This is an interest- ing and efficient change, and moves things forward.”

“Smart optimization of the individual tracker, to compensate for terrain and other factors, maximizing ground cover- age, not allowing light to hit the ground: This appears to be a smart optimization.”

![]()

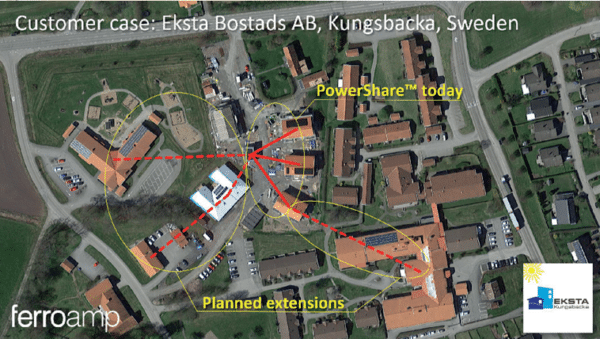

Joint winner: Ferroamp

PowerShare small-scale nano-grid

Ferroamp’s submission impressed the jurors with its potential to shape the ‘grid of the future,’ in which energy is shared and traded in a two-way grid with multi- ple generation points. Current electricity grids are centralized, top-down systems. But what would a bottom-up system look like? Ferroamp’s Powershare is a good example of such an approach. It is a small-scale DC nano-grid shared by a small group of consumers as a backup to the main AC grid. The Pow- ershare nano-grid consists of small-scale generation – usually PV and/or wind – and often also batteries and electric vehi- cle charging stations.

A number of successful projects in Swe- den have shown the feasibility of the solu- tion by connecting local office buildings in a small grid. This provides them with backup electricity in the case of a power outage, but also creates a local micro- economy and reduces their electricity tar- iffs. The company acknowledges that reg- ulatory hurdles exist in many countries in which there are few distribution compa- nies with a natural monopoly. However, the European Union’s ‘Winter Package’ has taken steps toward opening up mar- kets for micro-grids operating alongside traditional monopolies.

Jury comments:

“We see this as an innovation for the dis- tributed future, which gives much more freedom from utilities. This approach is the most futuristic, and could become the norm in the future. It is very innovative, and could have a huge impact in the long run.”

“It’s a very interesting stepping stone for multi-unit residential building arrays. This could be a very interesting application.”

“It’s not necessarily the newest, but one of the very positive approaches that has a very interesting future ahead of it.”

“Things that decouple us from the central- ized, utility-driven future, to a DG future are really what renewables are about.”

Highly commended: Cobalt Energy

PV-Serve and PV-Vision electroluminescence inspection

U.K.-based O&M expert Cobalt Energy is singled out in this year’s Array Chang- ing Technologies for its PV-Serve and PV-Vision solutions, which make on-site testing of modules considerably easier for plant owners, and thus contribute to push- ing ever more energy out of a PV power plant. Inspection services are not as sensational and headline-grabbing as other parts of the PV value chain, but they are the quiet achiever in the plant manager’s arsenal. Cobalt Energy offers the PV-Serve and PV-Vision solutions, which work together to enable nighttime electroluminescence inspections, dark I-V curve tracing, and bypass diode function checks.

First, PV-Serve injects a reverse current flow into a given string or module. Then PV-Vision can capture high definition video and photographs of electrolumi- nescence. Active cells emit a bright grey or white light, while damaged or inactive cells appear darker or even jet black. Detectable defects include: mechanical stresses, manufacturing defects, potential- induced degradation (PID), and bypass diode failures. Asset owners who make use of Cobalt Energy’s technology will certainly save time, money, and a few headaches when they uncover problems with their system as early as possible.

Jury comments:

“The super mobile units presented here, especially the EL camera, are pretty unique, and help to hold manufacturers and EPCs accountable for the equipment that is being installed.”

Finalist: Stäubli

Power-Blox

Accurately sizing and easily installing semi-permanent off-grid applications has hitherto been no easy task. As a PV sys- tem consists of a range of power electron- ics that must be connected and designed in the correct way, proper engineering was traditionally required. The result has been fixed bespoke systems with a stiff layout. Any adaptations had to be meticulously planned and executed by skilled staff. Stäubli’s Power-Blox concept addresses these issues by combining all necessary components into a single piece of equip- ment. The system comprises boxes that contain all relevant electrical hardware, delivering 230 AC to any mini-grid. Its modular design allows users to remove and add cubes depending on what they currently need. This feature permits users to downsize, extend, or even split the grid without the need for engineer- ing and system design or redesign. Also, mini-grids have either suffered from over- sizing resulting in lower ROI, or under- sizing resulting in lost revenues. Power- Blox allows system operators to utilize just the number of blocks that are required to maximize ROI. Additionally, finding skilled personnel to design and monitor the grid can become complicated the more remotely a grid is installed. Stäub- li’s concept does not need a master unit steering the mini-grid, but each box com- municates with and reacts to what the rest of the grid is doing, using Stäubli’s pat- ented swarm technology. This brings a range of advantages, like the benefit that splitting the grid does not require addi- tional components, or that the grid cannot be knocked out by the failure of a single component, as would be the case in tradi- tional mini-grids.

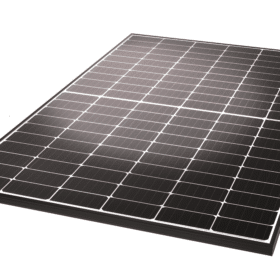

Finalist: Hanwha Q CELLS

Finalist: Hanwha Q CELLS

Q.PEAK DUO-G5 module

Hanwha Q CELLS’ mod- ule series Q.PEAK DUO- G5 comes in four variet- ies: 315 W (minimum 18.7% efficiency), 320 W (minimum 19% efficiency), 325 W (min- imum 19.3% efficiency), and 330 W (minimum 19.6% effi- ciency). The monocrystalline modules contain 120 half-cells and a six busbar design. The high-tech aluminum frame is certified for high snow and wind loads, at 5,400 Pa and 4,000 Pa respectively. The modules are also available as the all- black Q.PEAK DUO BLK-G5. Finally, the performance warranty is nothing to be sneezed at: Hanwha Q CELLS guar- antees at least 85% performance in year 25 to allay any investors’ concerns. TheQ.PEAK DUO-G5 series continues to push the envelope and raise the bar for competing modules in terms of efficiency, durability, and clean design.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.