Sustainability front of mind

As a part of the UP Initiative, pv magazine is introducing an award for Sustainability for the first time in its 2019 roster of awards. Highly recyclable products – those that do away with hazardous materials or exhibit a striking reduction in carbon intensity, as examples – will be awarded at the end of the year with the Sustainability Award. Make your mark with the UP Sustainability Award.

Award season is an opportunity to get a clearer picture of the technology trends shaping the PV industry. And by extending our awards schedule across three distinct ‘windows’ throughout the year, some intriguing developments are already beginning to appear.

In addition to increasing our opportunities to enter, pv magazine has also introduced five distinct technology categories for the awards, giving different component and technology groups a chance to shine. The categories are: Materials, Tools, Modules, Inverters, and BOS.

Five small juror groups of industry experts, with specific areas of expertise, are currently being assembled to review, assess, and evaluate each entry – with those judged Outstanding Entries qualifying for Annual Awards in each category at year’s end.

As was expected in this first award round of 2019, which coincides with Intersolar Europe – now a part of The smarter E, PV power plant components far outnumber production technologies. Entrants in the module, inverter, and BOS categories feature more prominently than materials and tools – a testament to product releases being targeted at specific end markets.

The trends

On the module front, everything is black – reflecting the continuing rise of monocrystalline wafers and cells. Bifacial, too, is prominent and five-busbar appears the default high efficiency option – before the switch to MBB is made. In tooling, equipment for ECA application is a standout – particularly well suited to heterojunction production, as is flashing for high-efficiency cells and modules.

In terms of power electronics, central inverter suppliers are paying particular attention to advanced cooling solutions, reflecting the growing importance of supplying the Sun Belt region. And in residential applications, communication interfaces continue to improve, with a number of suppliers going 4G. At the system level, attempts to expand application opportunities for PV are notable, and a system to allow for complete arrays to be installed on water – modules, inverters, transformers, and all – stands out.

Given the revamped award structure in 2019 and Intersolar’s early arrival, the first round of award assessment has not been completed. However, a selection of some of the particularly interesting applications have been highlighted in the following pages.

Swan dives into transparent backsheets

JinkoSolar Swan Bifacial module series

JinkoSolar’s new Swan Bifacial series modules bring together a number of efficiency-boosting technologies with a transparent backsheet – resulting in a product that is both different and similar simultaneously.

Jinko is coupling bifacial, larger format, half-cut cells in its Swan Series, with DuPont’s new Clear Tedlar transparent backsheet – in what the company claims is a product that combines high performance with a lack of complexity.

Jinko’s larger 158.75 mm² mono PERC full cells deliver 380-400 Wp front side output in a 144-HC-cell configuration, no

meagre achievement, however the back side is where the action is at. The use of DuPont’s transparent backsheet allows for up to 20% rear side energy gain, without the bulk and racking challenges that glass-glass brings with it. Both sides counted, Jinko claims up to 435 Wp in output.

Jinko says the Swan is 7-9 kg lighter than an equivalent glass-glass module – coming in at 23.3 kg compared to 31.8 kg. This, the manufacturer claims, results in reduced costs for installation labor, mounting structure support posts, and in transportation. The Swan also does away with the need for rubber-lined fastening clamps, required for glass-glass and which cost 20% more than those required for framed modules, according to Jinko.

Alongside DuPont’s claims of superior durability and color stability for its backsheet, Jinko notes that white mesh can be printed onto the backsheet increasing inner laminate reflection and delivering a 5 Wp module power boost. The module is reported to be undergoing Cradle to Cradle certification – making it well placed for the inaugural pv magazine Sustainabiity Award.

Hunting high power

Hunting high power

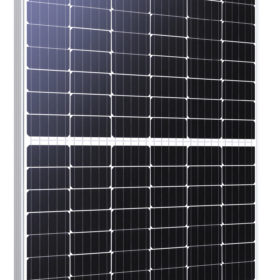

Risen Jäger series

Risen is demonstrating that there’s more to high powered modules than bifacial with its Jäger series, which brings together high-efficiency mono PERC half-cut cells, in a split module configuration and multi-busbar cell interconnection – MBB is not default to the Jäger series, however. The Chinese manufacturer has fitted larger cells and more of them onto its module, with 156 HC cells arranged in a doubled 6 × 13 configuration in its utility-scale format. Full cell size is 158.75 mm2.

And the combination of technologies appears to be paying off. Power output for a 156 HC Jäger cell comes in at

415-435 Wp, with a module efficiency of 20.1%. Risen reports its 3.2 mm front glass is treated with both anti-reflective and anti-soiling coating – making it suitable for Sun Belt applications.

On a cell level, Risen highlights its deployment of selective emitter, low firing temperature, and “enhanced current injection” techniques, along with “double side passivation” as being behind its mono PERC cell performance. Jäger appears to be an elegant module solution, without pulling out all the high-efficiency stops.

Total black for power and style

Sunerg Solar Energy XT Power

Sunerg Solar Energy’s XT-Power modules utilize mono cells, cut and shingled using conductive adhesive, on a black backsheet with black frame – delivering style and substance. And from an Italian manufacturer, the focus on aesthetics and performance appears somewhat fitting.

The XT-Power modules are produced at the company’s 100 MW Italian fab using a patented cell cutting and assembly solution that was developed in the United States. XT-Power modules are targeted at residential applications, a step up from full or half-cell ‘all black’ modules, where aesthetics do factor into the purchasing decision. High power may also be preferable in residential applications, where roof space may be limited.

And power output is certainly not forgotten on the XT-Power module, with 20% module level efficiency delivering 60 cell output of up to 360 Wp. Sunerg highlights that the XT-Power can guarantee 86% power output “even after 25 years.” A Ferrari of a module? Perhaps, while shingling remains far from mainstream production.

Glass-glass without the weight

Glass-glass without the weight

Phono Solar Bifacial TwinPlus Mono

Phono Solar’s Bifacial TwinPlus Mono ticks many of the boxes of high-efficiency modules in 2019: mono PERC, HC cells, 5BB, and bifacial. It also deploys a twin module configuration, however does not manage to fit in more cells when compared to rivals.

What sets aside the Bifacial TwinPlus Mono from other Intersolar Europe 2019 edition award entrants is that Phono has gone with a thin glass-glass encapsulation. The 2 mm glass sheets result in a relatively light dual glass module at 25 kg. Thinner glass is available on the market, however.

The Bifacial TwinPlus Mono comes in at power classes of 375-390 W in 72 full cell configuration (144 HC) and up to 325 W for 60 full cell. Besides its light weight, the Bifacial TwinPlus does not set the world on fire. However, it is a welcome entrant to the high power output game and may prove attractive to developers, EPCs, and installers who are familiar with, and accustomed to glass-glass installation. Glass-glass and bifacial: more of a classic solution in the fast moving high-efficiency segment.

Selective optimization

Huawei SUN2000 3/4/5/6/8/10KTL-M0

Huawei’s new Sun2000 KTL-M0 inverter series available from 3-10 kW is lighter and more user-friendly than ever. The inverter weighs in at a mere 17 kg making one-person installation possible without much of a hassle. The inverter’s energy management system no longer has to rely on a Wi-Fi connection, as it features a 4G dongle, making carport installations, or installing the inverter in remote parts of the home easier.

The manufacturer promises that a storage system can be fitted without a makeover of the array’s cabling layout and does not require any further power electronics. Additionally, Huawei says that it has fiddled with its cable connector design, making the removal of the front cover of the inverter unnecessary. This not only improves installation time but also ensures that the factory condition is not tampered with and full ingress protection is guaranteed. The Sun200 KTL-M0’s party piece is the possibility to deploy PV optimizers only to those modules that may be at risk of partial shading, rather than having to deploy the optimizers to the whole string.

Ice ice baby

Ice ice baby

ABB PVS980-58

For the first time in the European market, ABB will offer a high-power 1,500 V central inverter, which is plug-and-play ready with the company’s power block solution. Featuring a proprietary three-level power conversion topology, the system is said to have a high DC/AC ratio of up to 2.5, delivering 5 MVA at 690 VAC. ABB touts that its new central inverter solution provides a 30% higher energy density than its previous model. Squeezing incrementally more power into smaller cabins does have effects on heat dissipation, however. ABB says that it deploys a combination of a thermosiphon and a forced-air cooling system for this new inverter, which maintains low operating temperatures around heat sensitive components. According to the manufacturer, this also increases the lifetime of such equipment.

Small but brave suitcase

Sungrow SG250HX

Sungrow has introduced its 250 kW string inverter SG250HX, claiming it is the most powerful string inverter on the market. It comes with 12 maximum power point trackers and is compatible with bifacial modules.

The system features a flexible block design allowing for up to 3.15 MW or 6.3 MW blocks, making it ideal for utility-scale applications, Sungrow says. Manufacturer information reports that the “suitcase-sized” 95 kg inverter can operate without derating at temperatures of up to 40°C. The SG250HX features some innovations, such as smart air cooling technology, custom semiconductors, efficient modulation algorithms, and magnetic integration technology. With IP66 and C5 anti-corrosion grade, the compact inverter is resilient in harsh conditions and reduces the overall cost.

The early bird catches the worm

The early bird catches the worm

Solis 3P 4G 5-20 kW inverter series

With a range of three-phase inverters, Solis is bringing a new squad to the residential market. With an increasing focus on smart management of the inverter’s functions, Solis has added a 4G communication interface to its new series. The new interface allows it to work around a weak Wi-Fi signal should it ever be unstable or out of reach.

On the installation front, Solis says that with a dual-MPPT design and the claim of 98.7% efficiency, a comparatively high yield is promised by the manufacturer. Additionally, Solis says that its suite of products incurs low harmonic distortion against the grid with a THDi of less than 1.5%. With a startup voltage of just 180 V and an MPPT range of 160-850 V, the manufacturer claims that its product can start converting electricity from even earlier in the day, through to later in the evening, when the yield is lowest. Equipped with modern artificial intelligence technology, Solis says its new inverters are well equipped to take up the new tasks for inverters as they are progressively integrated into smart Internet of Things applications.

PV’s Austrian army knife

Fronius Primo Gen24 Plus 3-6 kW and Fronius Symo Gen24 Plus 6-10 kW

Residential PV has ridden a wave of popularity across the globe – in many regions, not least because of its promise of keeping the lights on and fridges cool, while your neighbor is dealing with yet another outage. With the Primo and Symo Gen24 Plus solutions, Fronius has brought to the market PV inverters that can provide basic emergency power even without the addition of battery storage, thanks to its PV Point feature. The addition of a storage system then allows for full backup supply. For those who would only seek to keep a few essentials running while the power is out, this is a low-cost option, as battery storage might still lack financial appeal in some markets, where other use cases are yet to be found.

Other functional highlights of the product include integrated data communication, dynamic peak management, and multi-flow technology for its hybrid inverter function. Two MPPTs and two DC inputs, which can accommodate the entire AC output of the inverter, ensure the efficiency of the system in every condition.

Water-free cleaning, no rails, no damage

Water-free cleaning, no rails, no damage

Miraikikai Type 2

The type 2 cleaning robot from Japanese company Miraikikai builds on experience and industry feedback to create a compelling case for robot cleaning solutions, particularly in arid regions. Miraikikai’s Type 2 robot can clean arrays at speeds of more than 2,000 m²/hour. The robots operate autonomously and can be carried in between arrays, reducing the number of units required per megawatt. The company says that it can calculate the optimum number of cleaning cycles with the minimum number of robots for any PV project, and that compared to systems working on the basis of one robot per array, its solution can carry out the same level of cleaning with less than 1% the number of units, greatly cutting the initial cost. Another key feature added to the Type 2 robot is the ability to move autonomously over an array where the panels are not aligned. This was identified as a problem holding PV plant operators back from investing in cleaning robots – plants are often assembled over huge areas of varying terrain, and some height misalignment is inevitable. No rails: an attractive solution.

Tracking on thin air

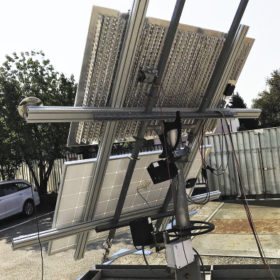

Sunfolding T29 tracking – Airdrive technology

U.S.-based company Sunfolding’s T29 takes a new approach to tracking, throwing out motors and torque tubes, instead relying on its Airdrive technology, which uses air to move module rows. Sunfolding says that the T29 uses far fewer components than other trackers, which reduces the time and complexity of installation, and can also eliminate the need for costly land grading. Doing away with more complex components such as gearboxes, torque tubes, and more also simplifies requirements at the O&M stage – the company states that thanks to fewer ‘wear points’ in the design, the T29 has 95% fewer maintenance locations.

The Airdrive is made using a polyester thermoplastic developed by DuPont, already proven in other demanding industrial uses. The company says the tracker has an expected lifetime longer than most PV modules, and that its 18 operational sites deployed since 2015 have demonstrated 99.9% uptime.

Whole systems afloat

Whole systems afloat

Zimmermann Zimfloat

Floating PV systems offer a whole host of advantages, and while they are a fast growing phenomenon in several global markets, there is still a lot of work to be done in terms of optimizing for installation on water and dealing with the inherent challenge. Mounting system supplier Zimmermann takes a whole system approach to floating solar. The company has designed a unique platform which, alongside floating modules, features floating platforms for inverters and transformer stations, as well as stable gangways for maintenance staff, cable ducts, and wave barriers. Its original approach is sure to turn heads.

Zimfloat is designed for large-scale installations. Several ‘boats’ can be assembled at once on the shore, and are then launched onto the water by a rolling conveyor. Zimmermann says in a test installation, workers were able to install a 2 MW system in around 2.5 weeks. And the system is designed with durability in mind. The company says it has simulated “all possible load combinations” for both waves and wind, and designed each component with these in mind. With plenty of questions remaining about the long-term stability of floating systems, Zimmerman’s system-level approach appears as sturdy as dry land.

Hybrid systems under control

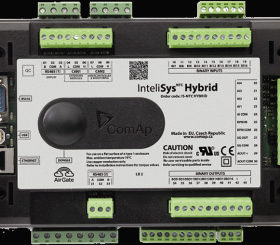

Comap InteliSys NTC Hybrid

Residents and businesses in remote areas not served by an electrical grid have long relied on diesel generators, and today there is a strong case for using these in combination with a PV array, to bring down reliance on more expensive and polluting diesel. Prague-headquartered company Comap a.s. is using its experience in manufacturing control products for diesel generators to facilitate the addition of PV to existing diesel gensets, and ensuring that system owners are able to maximize on fuel savings.

The InteliSys NTC Hybrid is a controller which continuously monitors data from all sources of energy, including solar, wind, genset, and batteries. The product facilitates communication between the PV inverters and the diesel genset, and communicates directly with Comap’s genset controllers to automatically select the most efficient combination of generation to maximize on fuel savings. Comap says it expects payback on the controllers to be achieved within six months, and further states its system will simplify the process of integrating PV into off-grid systems using diesel for power generation. Third-party control of solar PV and diesel generation could broaden the appeal of the emission busting and money saving solution. Diesel replacement from the sun appears more flexible with the solution.

Pooling resources for a renewable future

SolarEdge Virtual Power Plant

Efficient virtual power plant software will be a vital component of the future energy system, as more decentralized systems come online, and need to be managed as one to ensure supply and demand are balanced. Inverter supplier SolarEdge is one of the leading players looking to solve this problem and keep the energy transition running smoothly. SolarEdge’s Virtual Power Plant (VPP) delivers near real-time aggregated control and data reporting, allowing operators to pool distributed resources into a cloud, to balance the constantly shifting relationship between supply and demand.

SolarEdge says its VPP has benefits for all stakeholders. Grid operators are able to cost-efficiently meet demand, energy retailers are offered increased price protection, and PV system owners can increase revenues by including their power in this new market. The VPP can be used on SolarEdge’s own software platform, or integrated into third-party software and utility

management systems.

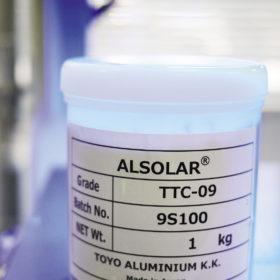

New horizons for silver-free solar

Toyo Aluminum ALSolar

Toyo Aluminum introduces its fully aluminum-based paste for advanced PV cell concepts. The company says that the paste is suitable for cell types including IBC, TOPCon, Mono-poly, and more. The paste is also reportedly capable of contacting p-type and n-type layers damage-free and with excellent contact resistance.

Using TOPCon as an example, Toyo says that replacing the back silver grid with aluminum can cut the metallization cost by almost 45%, and replacing the front side silver paste with aluminum increases this to 90%. In this example, silver pads of 20-30 mg are still required, though with advanced processes such as smart wire or IBC, it is possible to go 100% silver-free. Toyo says it has tested the paste in n-type passivated contact cells, and achieved a fill factor over 80%. Silver is proven, but doesn’t come cheap. Aluminum may present an alternative.

Cost-effective, built in cooling

Cost-effective, built in cooling

Coolback integrated backsheet & frame

Coolback is an integrated solution that aims to replace the traditional backsheet and frame common to solar modules. The solution’s key feature is an enhanced cooling capacity, achieved through heat sink technology on the rear side of the module, an enlarged surface that promotes a chimney effect and higher air turbulence, and a reflective aluminum outer layer. As well as lowering heat losses, the solutions uses materials that prevent moisture ingress, and a structure that reduces flexing of the module. Coolback’s creators say that this will increase both the daily output of the module, and its overall operational lifetime.

The product is suitable for all 60 and 72 cell modules, though will mainly be marketed for areas with high solar irradiation, and for utility-scale or large commercial projects. The company estimates that in such conditions Coolback could have a cooling effect of up to 15°C, resulting in a peak output increase of up to 7%. As Sun Belt markets grow, keeping cool becomes more powerful.

Less weight, more load

Borosil 2 mm fully tempered textured solar glass

India’s Borosil introduces its fully tempered, antimony-free textured solar glass, designed for glass-glass and BIPV modules. Borosil says that the glass offers uniform heat dissipation, for cooler operating temperatures and higher energy yield. The company notes that its thinner glass allows more light to reach the rear side of cells, and notes that glass-glass modules offer better protection than most backsheets against dust, humidity, and other hazards.

The glass has a load-bearing capacity of 150 newtons/mm², which Borosil notes is far higher than prescribed in industry standards, and says that it has been shown to perform with more than 8% additional output over any other solar glass. Borosil’s solar glass is also free of antimony and other toxic elements, and is safe to dispose of at the end of module life. The company notes that it is one of very few solar glass producers to have received certification from French research agency Solstice as having met the parameters set by the Government in recent tenders. Thin, strong glass for glass-glass bifacial modules appears important – antimony-free a sustainability bonus.

Longer pulse for reliable efficiency characterization

Longer pulse for reliable efficiency characterization

Gsolar long pulse solar simulator

High-efficiency cell concepts, such as PERC or IBC, require a longer flash duration to get an accurate measure of a cell’s performance. The cells have higher capacitance, meaning it can take them longer to respond to changes in light or voltage, and that standard flash measurements will often not be able to tell the full story of a cell’s or module’s ability. Gsolar presents its long pulse solar simulator, for highly accurate testing of the latest high-efficiency cell and module concepts. The flasher has a 10-150 millisecond sweep time, which Gsolar says is more than enough to measure current high-efficiency cells.

The company also notes that its flasher uses longer light pulse durations, while others in the industry rely on an algorithm to extrapolate the full results from a much shorter flash duration. According to Gsolar, this ensures more accurate characterizations, though the company does not address the issue that longer process times can present on a production line. The flasher is also upgradable, meaning that parts can be changed and tweaked to meet future testing requirements, so that manufacturers don’t have to invest in a complete new tool. Efficiency is always increasing. Accurate measurements impact the bottom line.

Busbarless cell interconnection for HJT

Teamtechnik Stringer TT1600 ECA

The Stringer TT1600 ECA brings an evolutionary approach to step change PV technology. Since 2002, Teamtechnik has been supplying its stringers for cell interconnection in module assembly. The TT platform has increased throughput steadily over almost 17 years, and allowed manufacturers to develop processes and optimize costs in their fabs at the same time.

Building on this strategy, Teamtechnik has now turned its attention to HJT module production, with a low temperature process for electrically conductive adhesive (ECA) cell interconnection. Rather than reinvent the wheel, Teamtechnik has

reimagined its proven TT stringer platform to the application of ECA. With a process temperature of 160°C, it is suitable for heterojunction (HJT) production – and has already been shipped to two customers. So, why shouldn’t HJT producers simply use other busbarless technologies, long promoted by other equipment providers? Because the T1600 ECA allows manufacturers to work with a wide range of material suppliers, allowing them to develop their own processes and reduce costs. Teamtechnik argues additionally that ECA does not suffer from any discoloring or degradation issues that may occur with foils used in wire-based interconnection processes. The Stringer TT1600 ECA can process close to 1,500 cells per hour. It is also suitable for light-capturing ribbon technology – delivering a further boost to power output. In terms of sustainability, ECA is entirely lead-free – doing away with lead-based solders. This year is looking to be the time at which HJT becomes a logical next step after PERC. That requires low temperature, high performance, scalable, and customizable cell interconnection technologies: Given this, the TT1600 ECA ticks a lot of boxes.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.