High throughput,

versatile laser platform

Innolas Lumion series

Laser process supplier Innolas has introduced its new platform Lumion, suitable for a range of crystalline silicon manufacturing processes. Lumion is a higher throughput, more cost-competitive generation of Innolas’s proven laser tooling. The new series is a dual line system, which can be integrated into cell lines, AlOx PERC rear-side ablation, and selective emitter laser doping. At the front end of module lines, or the back end of cell, it can be installed for half-cut cell production, for which Innolas has developed a laser direct cleaving (LDC) process, that leaves an undamaged cell edge and is suitable for heat-sensitive cells such as heterojunction. The Lumion platform can achieve throughput of 7,500 wafers/hour. To achieve the higher throughput, Innolas deployed a new device for the cell handling, to replace the linear turntable used in its Ultago high precision tooling. Accuracy on Lumion is still more than sufficient for PV, reports Innolas, with

±25 µm pattern accuracy and <±15 µm line-to-line accuracy. A “special focus” was on the LDC process for HC cell production, the company reports, with HJT cell cutting having been identified as an opportunity for new business. The new LDC process delivers high quality HC cells, with no shunting, melt, or dust, delivering significant advantages over scribe-and-break. Larger cell formats are also no problem on the tool, and it can handle 166 × 166 mm² wafers.

Sustainability issues take shape

Multi busbar stringing,

Multi busbar stringing,

as smooth as…

FuturaSun Silk MB1500

The Italian-Chinese stringer supplier FuturaSun has introduced a vacuum-solder process for the stringing of modules using round multi-busbar wires in its new SILK MB1500 platform, which offers a raft of new features. MBB technology is gaining momentum, however concerns do exist as to the quality of cell interconnection and accuracy of placement, due to the wires being both very thin and round. By virtue of soldering of the round MBB wires composed of tin-plated copper, in a low oxygen environment the risk of oxidation of the connections is in turn eliminated. And given the technology utilizes a vacuum process, the placement of the round wires is also facilitated. FuturaSun says that deploying MBB on the SILK MB1500 platform reduces the thickness and quantity of screen-printed silver metallization paste required, simultaneously boosting performance and reducing costs. The company says the SILK tool is more energy efficient than competitor processes, as it can use round wires, rather than transforming them into a rectangular profile through a thermal process before stringing.

The SILK MB1500 can hit a throughput of up to 3,000 cells per hour on a single track. It is modular and therefore upgradeable, with the company claiming that upgrades to 15 or even 18 wires can be carried out while retaining 98% of the tool’s original parts. The CEO of FuturaSun, Alessandro Barin, has lived in China for almost two decades, where the company’s stringers are produced. Thus, FuturaSun claims to enjoy a synergy between Italian technical know-how and Chinese industrialization. The result: silky smooth stringing.

Doubling up on light source for bifacial module flashing

GSolar GIV-200DS bifacial solar simulator

China’s Gsolar has developed a laboratory flasher capable of illuminating both sides of a bifacial module simultaneously. The flasher aims to help the industry answer increasingly important questions about modeling the performance of systems utilizing bifacial modules, potentially unlocking further optimizations to increase output, and simplifying the process of financing such projects. The GIV-200DS features dual xenon light sources, suitable for testing the latest module technologies being deployed in bifacial modules, including PERC and heterojunction. Gsolar says that the simulator can also be upgraded to meet testing needs for any future cell or module technology, eliminating the need for costly investment in new equipment every few years. The manufacturer notes that its bifacial module flasher was developed in cooperation with renowned PV testing labs, and is already in use in the testing laboratory of one leading module manufacturer.

Fast, accurate laser processes for

Fast, accurate laser processes for

roll-to-roll production

3D microFLEX platform

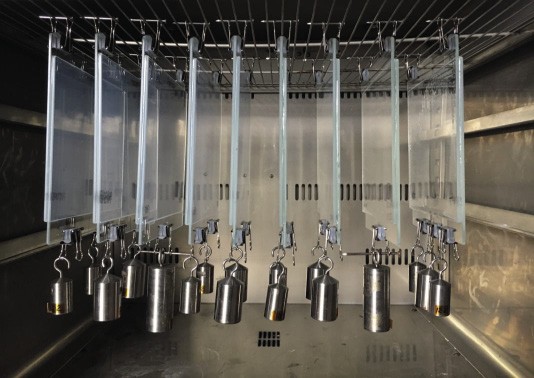

Roll-to-roll (R2R) production processes for thin film PV have long promised the potential for low cost, high throughput, and, importantly, flexible solar module production. However, scaling R2R thin films has proven difficult. 3D Micromac believes its new microFLEX platform can help, by handling larger substrate widths (web width), while increasing scribing accuracy and throughput.

A high level of scribe accuracy reduces dead areas, increasing module power output. 3D Micromac says that this is achieved due to the tool’s high level of substrate tension control and accurate guiding. Air cushions assist the substrate to travel over the rolls. The rollers themselves offer precision control, allowing for continuous motion or ‘stop and go’ operation – all on the same machine. Given that the microFLEX can handle substrate widths of up to 1,500 mm, 3D Micromac claims that hundreds of megawatts of production can be achieved on the one tool. The company also reports that the microFLEX platform is highly flexible, and able to scribe different patterns (P1, P2, P3, PT) on the same tool. The tool comes equipped with multiple laser heads, and utilizes constant optical inspection and alignment marks for added precision. In developing the tool the company says that it acquired a large amount of knowhow in terms of matching of substrate movement, tension control, and pattern recognition in optical inspection.

Its first generations of the tool, which were primarily employed in R&D applications, handled a 50 mm substrate, that scaled up over time. In non-PV applications, however, the tool has achieved a throughput of 50 meters/minute. Whereas thin film scribing on a rigid glass module is mature, R2R production, whether that be on metallic or plastic ‘foils,’ can enable lightweight, flexible PV products – increasing the number of applications for solar and allowing for cheaper and easier transportation. All of these added benefits also aid in reducing the carbon footprint of both the tool itself as well as the resulting end products.

Fast flasher for bifacial cells

h.a.l.m. cetisPV-IUCT-3600-BF

Flash testing equipment supplier h.a.l.m. presents its solution for bifacial cell testing in production. The cetisPV-IUCT-3600-BF combines two A+A+A+ xenon flash heads, controlled by one electronic cabinet. This allows the tool to simultaneously flash both the front and rear of a cell, accurately measuring its bifacial performance. The system performs front, rear, and bifacial I-V measurements under standard test conditions in a single three flash sequence. It can achieve throughput of 3,600 cells per hour, operating at a maximum of 3 x 30 millisecond flash duration per cell thanks to a new optical design of both light sources, a rework of the electronics and optimization of the advanced hysteresis system in combination with non-linear voltage ramp.

While bifacial flashers are typically much more expensive that their single light source counterparts, h.a.l.m. claims that thanks to the increased throughput, as well as flash tube lifetimes of up to five million flashes and low power consumption, its solution actually reduces the required investment per megawatt of production capacity. The firm estimates that initial investment for the cetisPV-IUCT-3600-BF is approximately 35% higher than that of a typical single side flasher. The solution also incorporates h.a.l.m.’s advanced hysteresis technique, which allows for the accurate measurement of high capacitance cells without any compromise on throughput. It is still early days for bifacial PV and the technologies that support it, and industry standards are yet to emerge for the treatment of bifacials cells in flash testing. While such tools represent an increase in capex investment compared to single-side flashers, they could help to provide certainty regarding the field performance of PV systems using bifacial modules, by assigning a firm value to the bifacial performance, a vital question when it comes to convincing investors and demonstrating bankability.

Qualifying TOPCon

Qualifying TOPCon

Meyer Burger CAiA Lab-Tool

Incremental technological improvement is powerful – a foundation on which the modern PV industry has been built. Meyer Burger is applying this principle to TOPCon cell production, which it describes as offering “a possibility of optimizing existing production lines in such a way as to boost the efficiency of solar cells to more than 23%.” But how to get there? Meyer Burger’s new CAiA Lab-Tool can be used by manufacturers to qualify their lines and tweak processes before a full-scale TOPCon upgrade. CAiA can deposit the “ultra thin” tunnel oxide and doped silicon passivating layers onto the cell, the two key TOPCon processes. Meyer Burger says that while the CAiA Lab-Tool is not designed for full-scale production, it can be deployed by manufacturers as a compact development tool, allowing them to “familiarize themselves with the process and customize it very quickly”, thus accelerating commercial application.

The Meyer Burger TOPCon process was developed in partnership with SERIS and is called monoPoly. It is a PECVD process, which means the deposition of both layers can be carried out on the same tool, which boasts a small footprint. The CAiA is a single-sided deposition process, meaning that “wrap around” effects are avoided, as are productive layers for the opposing side of the cell. Speaking to pv magazine during Intersolar, Adam Ga, Meyer Burger’s head of global sales said that TOPCon is a logical upgrade to PERC lines. “There is a huge capacity of PERC, that has been added to the industry in the past years,” said Ga. “PERC capacity [using AlOx] could reach 110 GW by the end of this year, plus or minus 10 GW depending on who you talk to. TOPCon is an upgrade on this existing capacity to the next capacity level.” Meyer Burger says its full-scale CAiA is “anticipated,” and given its long-proven track record in PECVD for AlOx PERC production, there’s every reason to believe it.

Raising the temperature on lab flash testing

Eternal Sun Spire temperature controlled module flasher

Eternal Sun Spire introduces its temperature controlled lab module flasher, which it says cuts the uncertainty in temperature coefficient calculations in half, from 10% down to 5%. The temperature coefficient of a module is an important factor in predicting its long-term performance, and in determining the yield predictions which factor into revenue forecasts and bankability assessments. Reducing the level of uncertainty in such calculations could be a valuable contribution to ensuring profitability and ultimately getting more projects built.

Netherlands-based Eternal Sun Spire’s latest innovations combines an A+A+A+ flasher with a single light source capable of a stable long pulse up to 270 ms, and extended spectrum between 300 and

1,200 nm. The chamber can maintain temperatures in the range of 10-85°C, with +/-1°C temperature uniformity throughout. The tester is suitable for measuring modules incorporating the latest technologies, including PERC, heterojunction, and IBC, and is designed to meet the R&D requirements of module manufacturers, research institutes, and certification test laboratories. Eternal Sun Spire also notes that the compact design of the system keeps its energy consumption low when maintaining a constant temperature. And finally, the temperature control chamber can also be retrofitted to Eternal Sun Spire flashers already deployed in laboratories.

ALD enabler

ALD enabler

DK Electronic Materials DK92X Silver Paste series

The DK92 series of high-efficiency silver pastes developed by Chinese manufacturer DK Electronic Materials (DKEM) aims to address the balance between lower firing temperatures needed for high-efficiency technologies such as PERC and ensuring a good contact window with reliable adhesion and high-speed printability. The series features a PERC paste (DK92 A/B) which DKEM says can achieve firing temperatures of 10 to 30°C, and offers enhanced adhesion on both monocrystalline and black silicon treated multi, and continues with ‘the trend of lower silver consumption.’ The paste achieves fine line printing down to less than 24 microns at speeds of more than 350 mm per second. Another in the series, DK92K is, according to the manufacturer, the first to be able to achieve acceptable contact performance with a stacked aluminum oxide/silicon nitride layer, making the mass production of the batch atomic layer deposition process for PERC possible, an innovation which could significantly lower production costs for PERC. The company notes that its DK92 series was developed in collaboration with leading cell makers and equipment suppliers, and has already been utilized and deployed in modules from tier-1 suppliers.

PID beating encapsulant material

Dow Mitsui Ionomer

Dow Mitsui’s ionomer encapsulant material is an ethylene copolymer, from the same family as well-known encapsulants such as ethylene vinyl acetate and polyolefin elastomer. According to its makers, however, the material exhibits a unique structure derived from ions embedded in the material, which it names ‘ionic multiplets.’ The sheet manufacturers, Kurabo, have utilized this structure in two separate encapsulant materials – the KuranSeal ES PV8700 and PV8800 series, with the PV8800 offering stable adhesion against various backsheet materials. Both are available as sheets in black or white and in various thicknesses from 0.1 mm to 0.6 mm. In glass-glass modules, a simulation conducted by Dow Mitsui showed that thanks to the material’s high shear modulus, stress is transferred more effectively between the two glass layers, allowing module makers to work with thinner glass – saving on weight and materials, without increasing fragility and the risk of cracking. The simulation suggests that ionomer laminated with 2 mm thick glass is equivalent to a polyolefin encapsulant laminated with 2.6 mm thick glass, in terms of bending and stiffness of the module.

Thanks to their crystalline structure, the materials exhibit excellent thermal conductivity, which the manufacturer says is superior to the performance of polyolefin-based encapsulants, keeping the module temperature lower. The manufacturer also claims that ionomer offers outstanding resistance to potential-induced degradation, thanks to the material’s high volume resistivity, and thermal stability – with a melting point above 90°C. Testing conducted by Dow Mitsui showed no degradation on electroluminescence imaging, after 1,000 hours of PID testing. Internal testing from Dow Mitsui also showed that the ionomer materials offer leading performance in terms of moisture protection, outperforming other common encapsulant materials in terms of water vapor permeability in more than 6,000 hours of damp heat testing.

Bifacial backsheet + engineered coating

Bifacial backsheet + engineered coating

Coveme Dymate Clear BACK / Dymat Clear FRONT

Italian backsheet manufacturer Coveme introduces its Dymat Clear Back, a transparent polyester-based backsheet for use in bifacial modules. As an alternative to glass-glass, which has quickly come to represent the majority of bifacial modules on the market, glass-transparent backsheet designs allow for lower module weight, lower cell breakage, and higher throughput in production. According to Coveme, Dymat Clear Back also exhibits better thermal conductivity than glass, lowering the module’s operating temperature.

The backsheet features a coating which the manufacturer says helps to capture more light on the back side, particularly in low light conditions at sunrise or sunset. In testing conducted by Coveme, the coating also achieved better abrasion resistance than competitors, which it says avoids degradation of the polymer, reducing performance over time. The manufacturer adds that a test installation featuring the Dymat Clear Back has been in the field for three years, and so far it has exhibited no yellowing, cracking, chalking, or bubbles. The manufacturer also offers a frontsheet as an alternative to glass, for producing flexible or lightweight modules where installation requirements demand this.

PID, LID-free with n-type + POE

Jolywood JW-T72N module series

China’s Jolywood continues to grow its reputation as a module supplier. And while some manufacturers are employing one or two innovative approaches, or materials, into their module concepts, Jolywood is going ‘all in.’Its new JW-T72N targets high performance with n-type bifacial cells, along with minimizing degradation through new encapsulant materials – in the form of polyolefin. The JW-T72N module series is robust, and high powered. In a 72 cell format, front side power output comes in at between 395 W and 415 W.

Deploying bifacial n-type cells, the JW-T72N series can achieve total power output, using a 405W module as a reference, of 502 W – assuming a 30% bifacial power boost. This is a significant step forward on previous products. Jolywood claims its new module series is both LID and PID-free, due to the deployment of n-type cells and polyolefin (POE) as encapsulant. In general, n-type cells are considered to be LID-free, although they can suffer from LeTID – as with many high-efficiency concepts. POE encapsulant has been demonstrated in Fraunhofer CSP testing to deliver better electrical isolation – substantially reducing PID in comparison to conventional EVA. Interestingly, Jolywood has gone with DuPont’s new Clear Tedlar backsheet, rather than a glass-glass format, which the company reports delivers a 20% lighter module. 3.2 mm glass has been used for the front glass. The module comes with a 30 year linear performance warranty, guaranteeing a 0.4% annual degradation after three decades under the sun and only 1% in the first year.

Dual-glass, dual-module approaching GW-shipments

Dual-glass, dual-module approaching GW-shipments

Longi Hi-MO 3 modules

First released in May 2018, Longi’s Hi-MO 3 high performance module series is now a mature product, and its “basic product” for supply into the Americas, EMEA, and APEC. And it has built up a considerable track record. Longi reports that 275 MW of the Hi-MO3 have been installed in Top Runner projects in China, and that orders of an additional 500 MW have already been placed. The Hi-MO 3 deploys Longi’s mono PERC bifacial cells, for which it is well known, in a dual-module design, with half-cut cells. In a 72 cell configuration (144 HC) it achieves a power output of between 360 and 385 W. Longi has gone with dual-glass encapsulation, however using 2 mm glass – which results in a dual-glass module with a weight of 25.5 kg. The dual or split-module design, along with HC cells, delivers the well understood advantages of a lower operating current and temperature, along with reduced hot spot risk.

Diagnosis: High-efficiency

Growatt – Max 50 ~ 80 KTL3 LV

Growatt has released a whole range of new inverters in its MAX series. The new equipment comes in 60 kW, 70 kW, and 80 kW power ratings for the three-phase 400 V models, and in 80 kW, 90 kW, and 100 kW for the three-phase 480 V models. The inverter features smart I-V curve scanning for optimized power conversion and higher yields. Additionally, the machine can detect failures of the modules, and other system components on the AC and the DC side, including grid quality control and grid wire impedance diagnosis. Using a quad core architecture, the inverter is said to perform these vital monitoring and diagnostic tasks at a higher speed and stability than has been the case before. Growatt asserts that its new range of inverters is breaking efficiency records and currently ranks as the top inverter in China for the most efficient 80 kW inverters, at a European weighted rating of 98.3%.

Density on a skid

Density on a skid

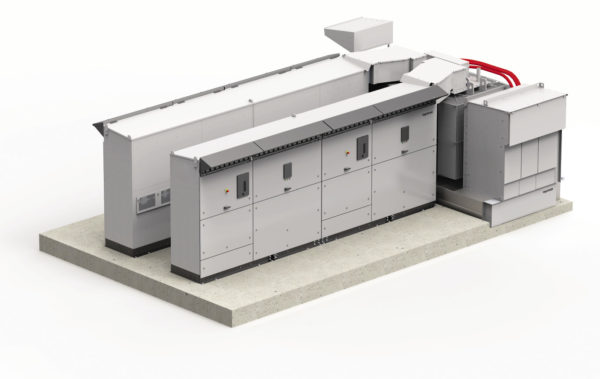

Ingeteam – Inverter Station (1660-7200 kVA)

Ingeteam is presenting its new Inverter Stations including switchgear and transformers combined on a single power skid. The product features Ingeteam’s B Series central inverter which comes with a rating of between 1,170 and 1,800 kVA, which can be scaled up to 7.2 MVA using up to four inverters at a time. According to the manufacturer, the inverter station shines with the greatest power density on the market at 317 kW/m³. A high power density can help with the installation process, as it is possible to smoothen shipping and field installation. Furthermore, higher power density also means that fewer inverters are needed.

The whole arrangement including a hermetically sealed and liquid filled

34.5 kV medium voltage transformer sits pre-assembled on the skid, for easy plug-and-play installation. On the side of grid interplay, Ingeteam’s B Series central inverters feature low voltage ride-through capability, reactive power deliverance, and active power injection control, among other things. These functions are becoming increasingly more important in markets where the share of variable renewable energy assets is high, or the grid is rather weak. The list of optional extras includes a meteo station and an extra energy meter for auxiliary services, as well as a high-speed communication interface for remote control and a SCADA system for enhanced oversight.

Combining the strings

Power Electronics – HEM

With the HEM 3.5 MW inverter Power Platform, Power Electronics launched the first 1741-SA UL-listed medium voltage inverter in the world. Since 2018, the company has deployed 1,000 Power Platforms in the U.S. The system comprises 36 DC input circuits of 1,500 V each. This makes the HEM ‘a central inverter with a string concept,’ as manufacturer Power Electronics puts it. The string inverter concept also applies to the inverter’s failure mitigation behavior, as it is composed of six field replaceable units. These can easily be replaced without the need for a full replacement of the entire inverter.

The HEM is not just a central inverter, but comes as a fully integrated system with a transformer and medium voltage switchgear, eliminating the need for additional connections between the LV and MV sides. On the matter of cooling, Power Electronics says that the transformer functions without the need for oil cooling, which according to the manufacturer, frees it of any need for maintenance, and eliminates the risk of spillages. The inverter cabinet itself also features a new cooling system. The system is a regular air cooling system, though through a technology called ‘Cyclone drive cooling’ the system does not need any filters. That in turn means that there are no filters to clean or exchange, which reduces the overall O&M costs. Thanks to its compact design and light weight the manufacturer asserts that the HEM can reduce installation costs and time, lowering the LCOE.

Stay tuned for BOS

The July edition of pv magazine global will feature the entrants into the BOS category for the 2019 awards. A host of smart software solutions, cleaning, and the latest bifacial tracking platforms will feature in the selection of highlights.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.